Application Background

In view of the characteristics of small batches of multi-batch bending parts, customers need to change molds many times a day. On the basis of robot automatic bending, WILA's automatic mold change solution can realize fully automated bending operations to the greatest extent, greatly improve the yield rate and bending efficiency, and thus achieve a higher return on investment.

Core Technology

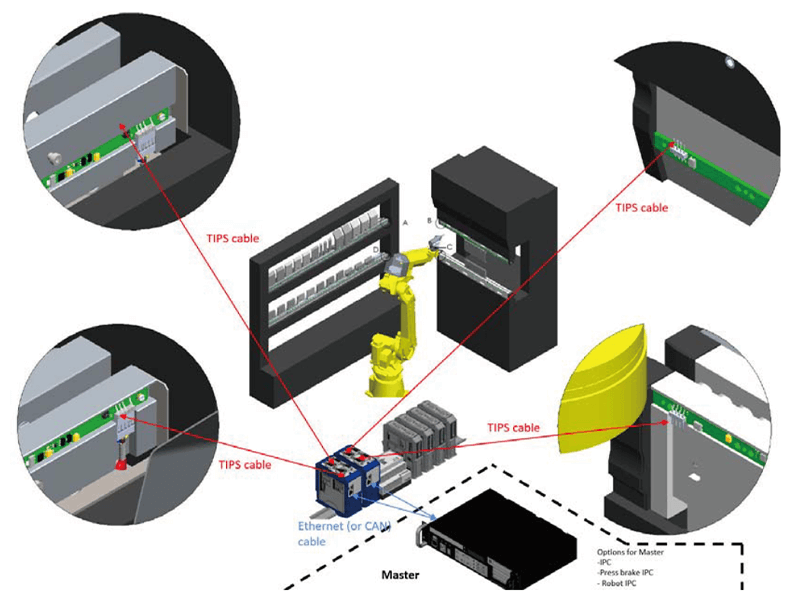

The automatic mold change used on the bending machine requires the support of three major systems: the bending machine system, the robot system, and the WILA automatic mold change system, as shown in the figure below.

WILA's automatic mold changing system is based on the following two core technologies:

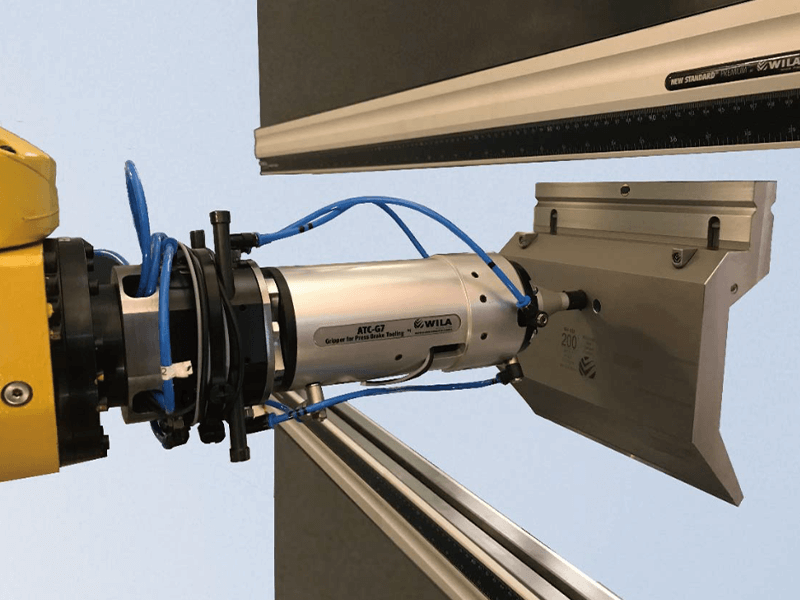

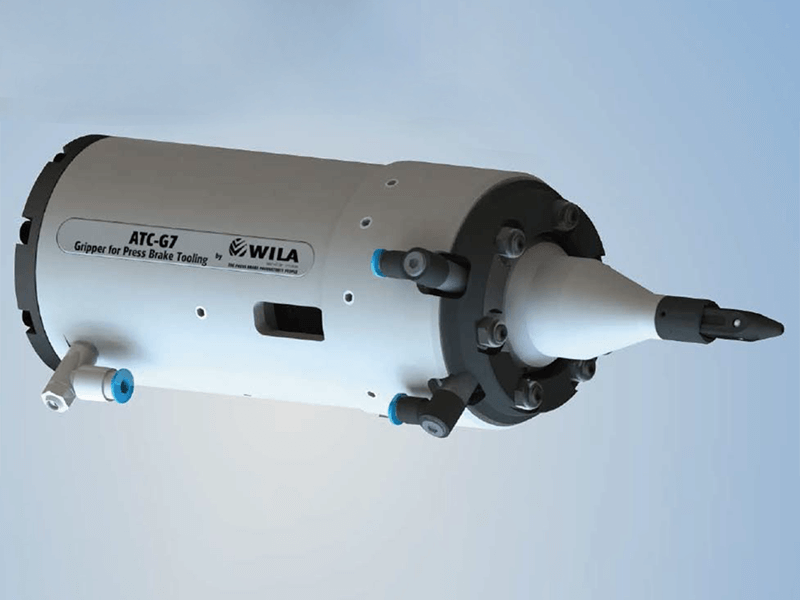

1.ATC (Automatic Tool Change) automatic mold change technology

It mainly consists of two parts: the ATC-G7 gripper and the ATC mold. As shown in the figure below, the G7 gripper can be easily integrated into the robot's quick-change plate. The ATC mold is designed with a special air path inside. The G7 gripper can release the safety button device on the bending mold through the air path, and then the mold can be loaded and unloaded in the bending fixture.

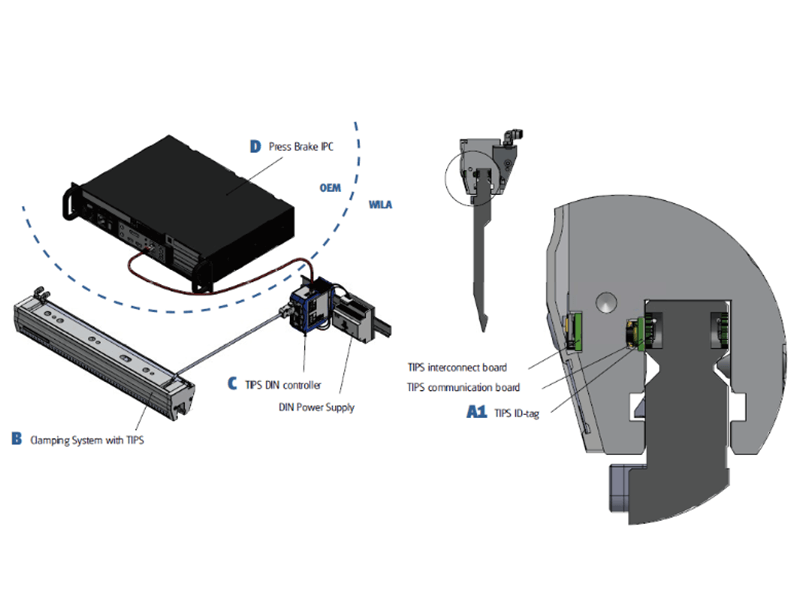

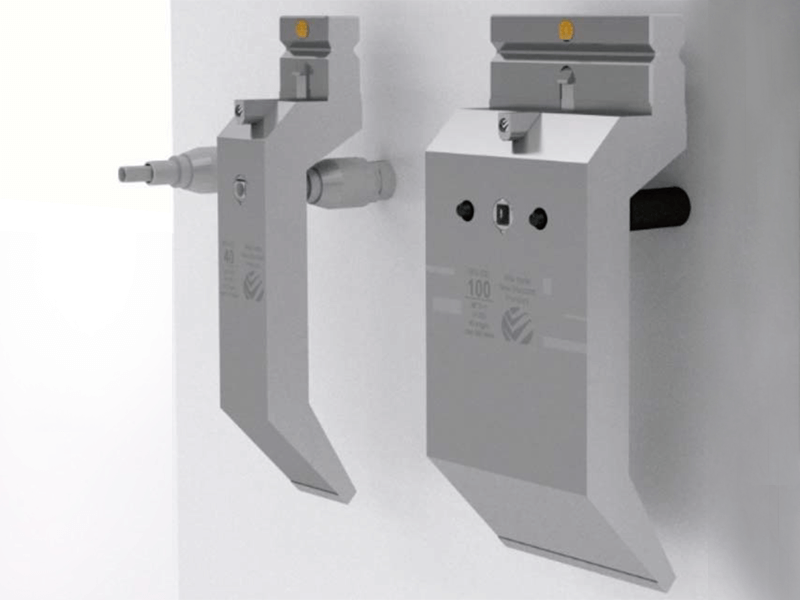

2.TIPS (Tooling Identification and Positioning System) mold identification and positioning system technology

It mainly comprises a fixture and a mold with a TIPS chip, as shown in the figure below. When the TIPS mold is clamped, the TIPS fixture can identify all mold information, including model, length, height, mold location, etc. The TIPS fixture can send the mold information back to the main controller of the system through Ethernet communication. The robot controller, the bending machine controller, or an additional industrial computer can be used as the main controller.

Program components

WILA's automatic mold change system can be integrated with various bending machine and robot brands in a friendly way, including the following products:

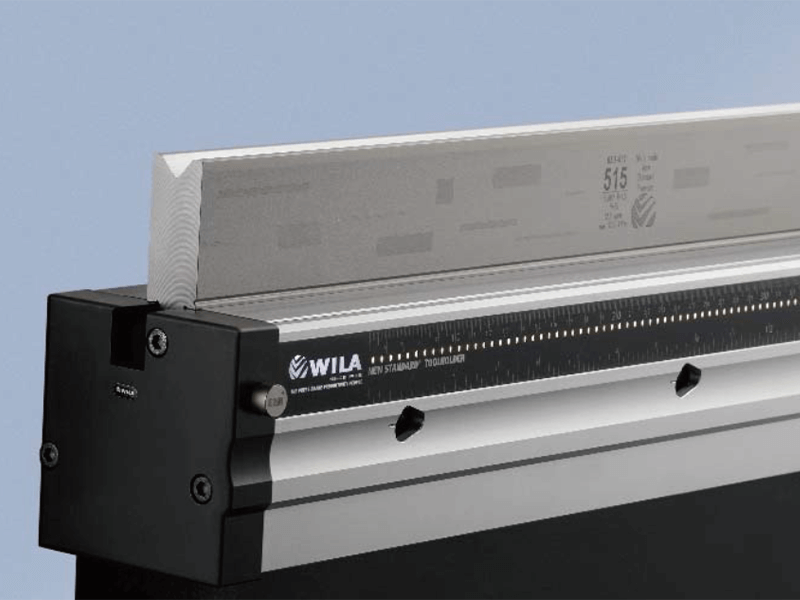

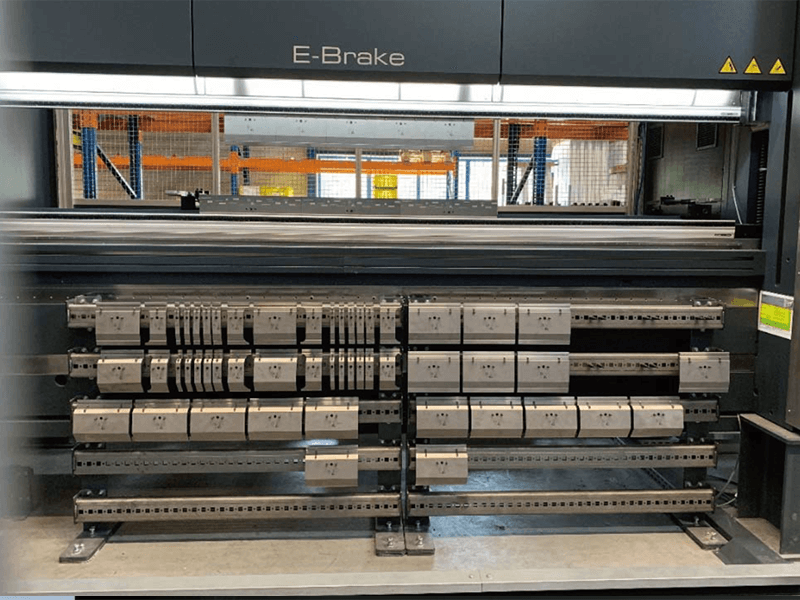

1.WILA hydraulic/pneumatic clamps used on bending machines

The main material of the fixture is high-strength CrMo alloy steel with a tensile strength of ≥1000 Mpa. The working surface has been CNC deep quenching and hardening treatment, with a hardness of up to HRC56 and a hardened layer depth of 3mm. Automatic clamping, and automatic centering of the bending line. A 3-meter-long clamp can be fully clamped in about 5 seconds. The fixture has a built-in Tx/Ty adjustment function, which can adjust the bending line and achieve local fine-tuning of the bending angle. The mechanical compensation workbench can accurately compensate for the deflection deformation of the bending machine and achieve high-precision bending.The fixture is equipped with a TIPS chip, which can identify the mold information on the fixture and transmit it back to the main controller.

2.The WILA G7 gripper used on the robot has the following features:

Applicable to all WILA new standard bending dies with ATC interface. Compact design, dimensions Φ70*256 mm, weight 2.5 Kg. The maximum allowable weight of a single mold is 12.5 Kg, and the allowable mold length range is 20~255 mm.

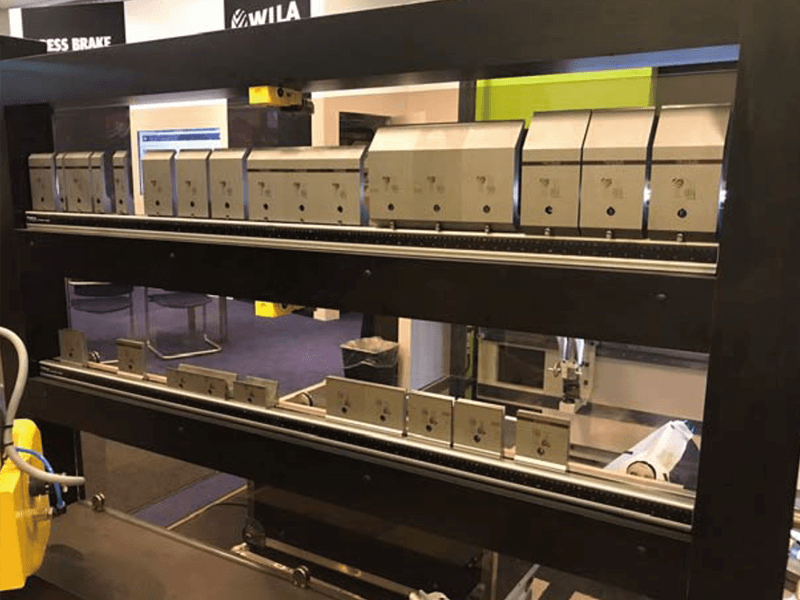

3.Mold storage device

The molds that are not put on the bending machine for operation temporarily can be stored in the mold storage device. You can choose the mold library or mold positioning pins. The mold library is a pneumatic clamp with a TIPS chip.

4.ATC+TIPS bending mold

Based on the traditional bending mold, the ATC automatic mold change interface is processed and the TIPS chip is installed.

About Us

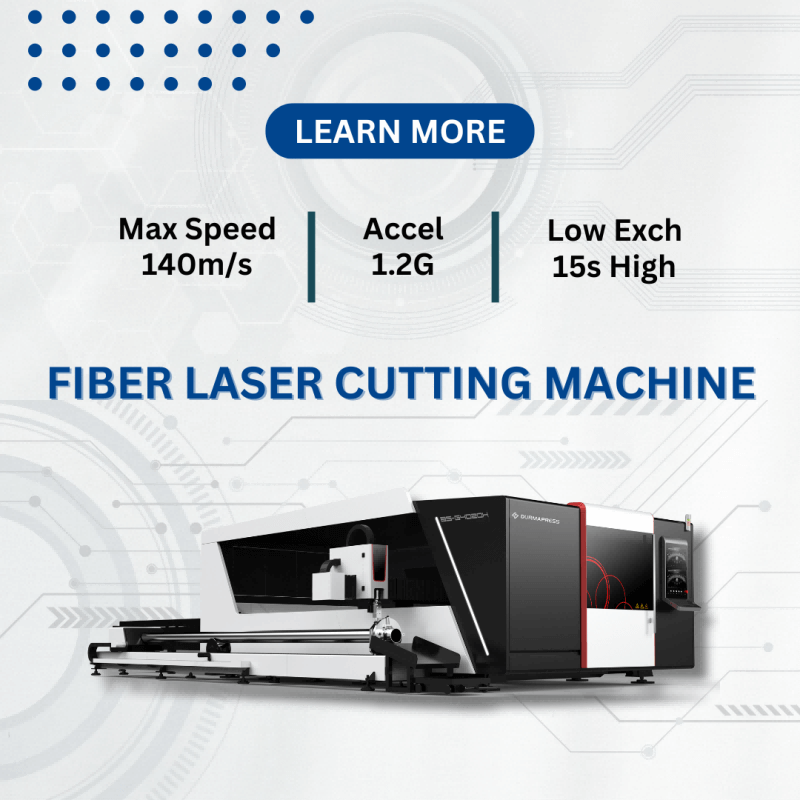

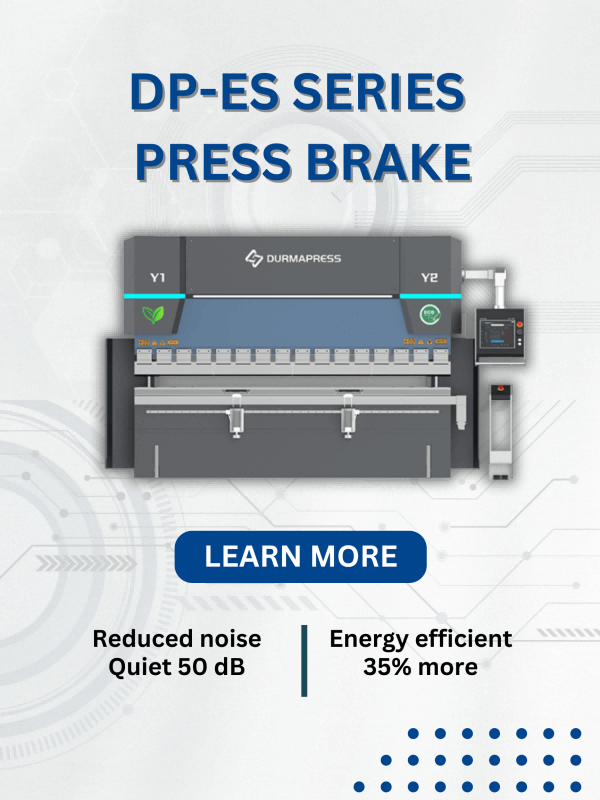

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)