What is LaserCheck?

LaserCheck is a bending angle measurement system that utilizes advanced laser technology and image processing to achieve high-precision angle measurements. It is commonly used in industrial production on equipment such as press brakes to measure the bending angles of various materials, including metal sheets and pipes. By installing LaserCheck on press brakes, operators can monitor the angle changes of workpieces in real-time during bending processes, ensuring the accuracy and consistency of each bend. Its operational principle involves projecting a laser beam onto the surface of the workpiece and calculating the angle of the workpiece by reflecting the beam back to sensors. Users can view measurement results and make adjustments through the system's display screen or connected computer software. This system's high precision, ease of operation, and application versatility make it widely used in industries such as automotive manufacturing, metal processing, and construction.

How LaserCheck Works

The working principle of LaserCheck involves projecting a laser beam onto the surface of the workpiece and then calculating the angle of the workpiece by reflecting the laser beam back to the sensor. This efficient angle measurement system is suitable for high-end series of press brakes. By precisely measuring the bending angle of each workpiece, LaserCheck ensures accuracy and consistency in the production process. The measurement results can be intuitively displayed on the system screen and also recorded and analyzed through software connected to a computer. This technology not only enhances production efficiency but also provides reliable means of quality control for users.

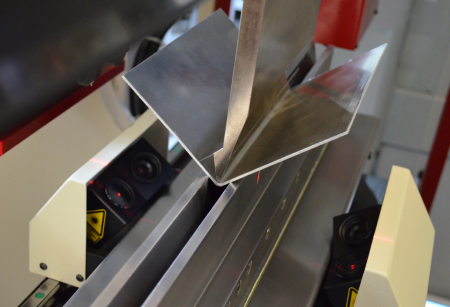

The connection between LaserCheck and the press brake.

The application of LaserCheck on press brakes is highly flexible and convenient. It can be directly installed on press brakes and integrated with the control system through simple settings. During operation, the laser beam is projected onto the workpiece to be processed, and then reflected back to the sensor. The system calculates the angle of the workpiece by measuring the angle of the reflected laser beam. Operators can monitor the angle of the workpiece in real-time during bending, using measurement results for timely adjustments and corrections to ensure the accuracy and consistency of each bend. This close integration makes angle measurement easier and more accurate, providing users with efficient production tools while ensuring the quality of the final product.

Advantages of LaserCheck Bending Angle Measurement System

High Precision Measurement

In the field of press brakes, precise angle measurement is crucial to ensuring the accuracy of each bend. LaserCheck utilizes advanced laser technology and image processing to achieve highly accurate measurements. When installed on press brakes, the laser beam is projected onto the workpiece, and the angle of the workpiece is calculated by reflecting the laser beam back to sensors. This means that operators can accurately monitor changes in the angle of the workpiece during bending processes, allowing for timely adjustments and corrections to ensure the accuracy and consistency of each ben

Simple Operation and Efficiency

Press brake operators need to make quick and accurate angle adjustments to accommodate the processing requirements of different workpieces. LaserCheck's operation is simple and intuitive. Simply placing the device on the workpiece allows operators to obtain measurement results and make adjustments immediately. This simple operation not only reduces the threshold for operation but also greatly improves the efficiency of the bending process. Operators can quickly adjust angles without affecting production, reducing setup time, and reducing the likelihood of operational errors.

Wide Applicability

Press brakes need to handle workpieces of various shapes and sizes, and LaserCheck has a wide range of applications. It can easily handle different types of workpieces, including large mechanical equipment and small components. The application of LaserCheck on press brakes is highly flexible, suitable for complex workpiece structures and tasks requiring high-precision angle control. Operators can trust LaserCheck to provide accurate and reliable measurement results, ensuring the accuracy and consistency of each bend.

Stability and Durability

Press brakes typically operate for long periods in industrial environments, requiring high stability and durability from equipment. LaserCheck is carefully designed to have excellent stability and durability, ensuring stable operation in various industrial environments. Whether in high-temperature, high-humidity, or dusty environments, LaserCheck can reliably operate. This stability ensures reliable long-term use, and its durability means that operators can rely on this system for continuous measurement work without frequent maintenance or replacement. This stability and durability make LaserCheck an indispensable angle measurement solution on press brakes.

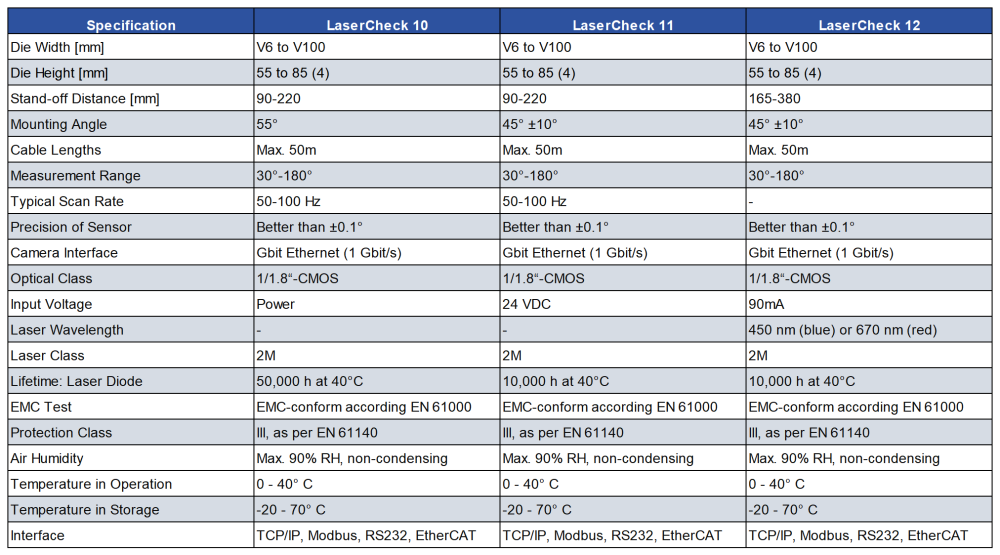

The representative products of LaserCheck

The representative products of LaserCheck include LaserCheck 10, LaserCheck 11, and LaserCheck 12.

LaserCheck Product Introduction

Component Introduction

Laser Measurement Equipment

- Includes laser emitter and receiver.

- The laser emitter generates a beam of light, which is received by the receiver after passing through the object.

- The receiver records the position and angle information of the light passing through the object for subsequent angle calculation.

Image Processing Unit

- Receives laser data and calculates the bending angle of the object through image processing algorithms.

- Can calibrate and process data to ensure the accuracy of measurement results.

Display Screen and Control Panel

- The display screen is used to show measurement results and system status.

- The control panel includes various buttons and control elements, allowing users to perform system settings and operations.

Bracket and Fixture

- Used to fix the measurement equipment on the object to be measured, ensuring stable and accurate measurement.

Measurement Process

Preparation

- Place the LaserCheck system next to the object to be measured and ensure there are no obstructions between the equipment and the object.

- Turn on the system power and wait for the system to start.

Calibration

- Before measurement, calibration of the system may be necessary. This typically involves adjusting the positions of the laser emitter and receiver to ensure accurate measurement results.

Fixing Equipment

- Use brackets and fixtures to fix the laser measurement equipment on the object to be measured. Ensure that the equipment is securely fixed in place.

Start Measurement

- Start the measurement process through the control panel or the operating interface provided.

- The laser emitter emits light, which is received by the receiver after passing through the object.

- The receiver records the position and angle information of the light passing through the object.

Data Processing

- The image processing unit receives laser data and calculates the bending angle of the object using algorithms.

- Real-time measurement results, including angle values and graphical representations, can be viewed on the display screen.

Result Display and Recording

- Measurement results are displayed on the screen, allowing users to visually observe the bending angle of the object.

- Users can also choose to record the results, saving them as files or exporting them to other systems for further analysis and processing.

Completion and Cleaning

- After measurement is complete, turn off the system power.

- Remove the equipment from the object and perform necessary cleaning and maintenance to ensure normal operation for the next use.

Practical Applications of the LaserCheck Bending Angle Measurement System

Automotive Manufacturing

In the automotive industry, the LaserCheck bending angle measurement system is widely used in the production processes of car bodies, chassis, and components. When combined with a press brake, LaserCheck ensures the accuracy and stability of car body structures. For instance, during the welding process of car body parts, LaserCheck can detect whether the bending angles of welded parts meet design requirements, thereby enhancing the quality and safety of automobiles. Moreover, for manufacturing bent components of car bodies and chassis, the high-precision measurements of LaserCheck help manufacturers ensure that each part meets specifications, ensuring consistency and safety of overall car performance.

Construction and Structural Engineering

In the field of construction and structural engineering, the combined application of LaserCheck with a press brake plays a crucial role. During the construction of buildings and structures such as bridges, LaserCheck accurately measures the bending angles of steel structures, concrete components, etc. When steel or concrete components need to be bent, LaserCheck assists operators in monitoring and adjusting angles during the bending process, ensuring structural stability and durability. Additionally, LaserCheck can be used to monitor deformations and displacements of buildings, promptly identifying and addressing potential safety hazards. This combined application enhances construction efficiency and quality control in construction and structural engineering.

Metalworking and Manufacturing

In metalworking and manufacturing industries, the combined use of LaserCheck with a press brake is equally significant. For example, in the manufacturing processes of metal pipes, fittings, frames, etc., LaserCheck is used to measure the bending angles of these metal components. This is crucial for manufacturing high-precision metal components, such as engine parts in the aerospace industry and hull structures in the shipbuilding industry. By combining with a press brake, operators can monitor and adjust the bending angles of metal components in real-time, ensuring precision and consistency of each part. This combined application enhances production efficiency and product quality in metalworking and manufacturing industries, providing reliable machining solutions for enterprises.

Comparison of Performance Parameters with Other Measurement Systems

Accuracy: LaserCheck possesses high-precision measurement capabilities, typically achieving accuracy to several decimal places. Ease of Operation: Compared to traditional measurement systems, LaserCheck offers simpler operation, allowing users to complete the measurement process with ease. Applicability: LaserCheck is applicable to various industries and scenarios, including automotive manufacturing, construction engineering, metalworking, etc., with a wide range of applications.

Comprehensive Advantages of LaserCheck

High-Precision Measurement: Utilizing advanced laser technology and image processing techniques to ensure measurement accuracy. Ease of Operation: Simple operation reduces the complexity for users. Wide Applicability: Applicable to multiple industries including automotive manufacturing, construction engineering, metalworking, etc. Stability and Durability: Demonstrates good stability and durability, capable of stable operation over extended periods.

Conclusion

The LaserCheck bending angle measurement system demonstrates significant application value and advantages in industries such as automotive manufacturing, construction engineering, and metalworking. Its high-precision measurement capability, ease of operation, and wide applicability make it a preferred tool within the industry. Choosing LaserCheck not only enhances production efficiency and product quality but also helps enterprises reduce costs, save time, and improve competitiveness. For enterprises aiming to stand out in intense market competition, selecting LaserCheck is undoubtedly a wise decision.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)