In the metalworking industry, press brakes are a common piece of equipment used for bending and shaping a wide range of sheet metal. For beginners, operating a press brake may seem simple enough, and they often think that bending a part is as easy as inserting the tool into the proper position and then maneuvering the punch up and down. However, such an idea oversimplifies the skills and requirements for operating a press brake, which in fact requires a great deal of skill and experience on the part of the craftsman in order to truly master the machine and operate it efficiently.

Understanding the machine

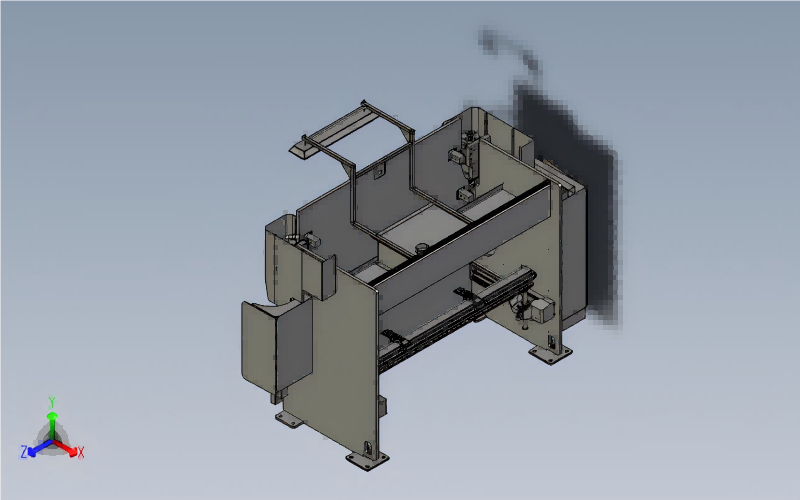

Bending is a core step in sheet metal operation, which not only concerns the shape of the final product, but also affects productivity and quality. A highly skilled sheet metal operator needs to have an in-depth understanding of not only the press brake itself, but also a comprehensive grasp of the entire bending process. This includes an in-depth understanding of the structure of the press brake, its operating principle, the functions of the controller, and the various tools involved.

Programming the controller is an important part of press brake operation. Operators need to be proficient in programming skills, be able to set bending parameters according to actual needs, and flexibly utilize functions such as dwell, acceleration, deceleration, etc., in order to achieve precise bending results. This not only requires the operator to have solid professional knowledge, but also rich practical experience and keen insight.

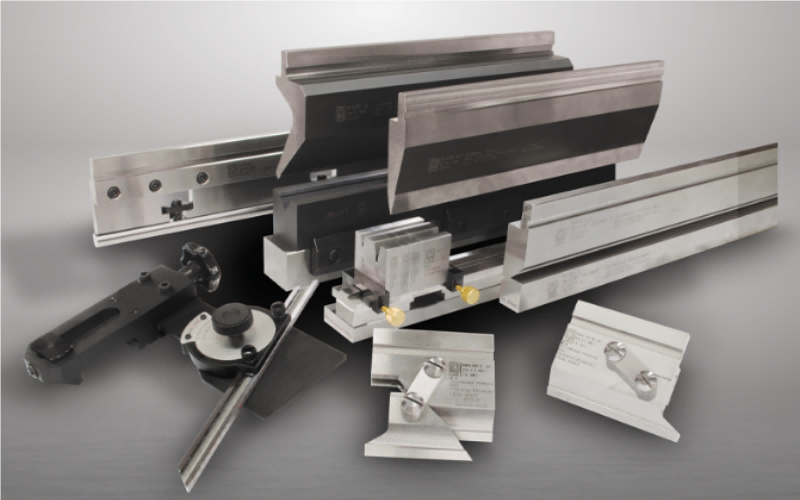

At the same time, choosing the right tools is also a key factor in ensuring bending quality and safety. The bending of different materials requires the use of different tools, and the selection of the tonnage of the tool also needs to be determined according to the thickness and hardness of the material. If an inappropriate tool is selected, it will not only lead to poor bending results, but may also cause damage to the machine and tools. Therefore, operators need to understand the characteristics and scope of application of various tools, and be able to choose the right tool according to the actual needs.

In addition to choosing the right tool, the operator also needs to master the correct method of use. When using the tools, it is necessary to pay attention to keep the tools clean and sharp, so as to avoid the impact of bending quality due to tool wear or damage. At the same time, pay attention to safety during operation to avoid accidents due to improper operation.

In addition, regular machine maintenance is also an important measure to ensure the long-term stable operation of the press brake. Operators need to be responsible for the daily maintenance of the machine, including cleaning, lubrication, fastening and other tasks, and keep detailed maintenance records. This helps to identify and solve problems in time, extend the service life of the machine and ensure production stability.

In terms of tool selection and use, operators also need to understand the differences between different tools. For example, traditional planing tools and hardened precision grinding tools differ in terms of material, process and service life. Operators need to select the right tools for their actual needs and understand how to properly use and maintain these tools.

Finally, operators need to recognize that tools, while durable, are also consumables. As they are used for longer periods of time and with increased wear and tear, the performance of the tools will gradually deteriorate and eventually fail. Therefore, operators need to check their tools regularly for wear and replace them when necessary to ensure bending quality and machine safety.

In summary, knowledge of the machine, mastery of the programming controller, selection of the right tools, knowledge of the correct use of the tools, and regular maintenance of the machine are all important factors in ensuring the success of a sheet metal bending operation. A highly skilled sheet metal operator needs to continuously learn and practice these skills to improve his professionalism.

Extended Material Properties

Each material has its own unique characteristics in terms of how it behaves under pressure, mainly in terms of its physical properties and yield limit. For example, cold rolled steel, as a base material, has a deformation capacity under pressure that lies between stainless steel and aluminum, and requires a tonnage that, while less than stainless steel, is greater than aluminum. Stainless steel, on the other hand, has a higher resilience compared to cold rolled steel, which makes it necessary to pay special attention during processing. Aluminum, on the other hand, usually requires less tonnage under pressure than cold rolled steel and stainless steel because of its light weight and good electrical conductivity.

In addition, variations in material thickness, grain size and orientation can have a significant effect on the final bending result. This requires operators to have an in-depth understanding of and the ability to adapt to these variations, as each day's work can be challenging due to differences in material properties.

Ability to read drawings

Mastering drawing reading is one of the key skills necessary for a press brake operator. By understanding the dimensions, tolerances, and types of projections (first and third angles) on a drawing, it is possible to ensure that the parts produced are accurate. This process not only requires the operator to have an in-depth understanding of geometry, but also the ability to recognize engineering drawings in an expert manner. Persistence and learning are the keys to success in a press brake operator's career path. A career as a press brake operator can be rewarding, but it requires a great deal of skill and focus. Even experienced operators need to learn and adapt to new challenges every day. This industry provides opportunities for continuous learning, giving aspirants the chance to become highly skilled master craftsmen.

Reading the operator's manual is fundamental to understanding the machine's capabilities and how to operate it. The operator's manual details the machine's structure, functions, operating procedures and safety guidelines, and is a code that every operator must familiarize himself with and follow. Learning proper tool selection and maintenance techniques is critical to ensuring a job well done. Tool selection should be based on the type and thickness of the material, while maintenance is the key to ensuring the machine's long-term stable operation.

An in-depth understanding of the properties of different materials and their behavior under pressure is essential to the operation of a press brake. Different materials require different handling and pressure tonnages, and this knowledge can help operators avoid surprises during the process. Knowledge of drawing reading skills can ensure that the parts produced are dimensionally accurate and meet design requirements. This is an indispensable part of an operator's job.

Persistent learning and continuous self-improvement is an important guarantee that the press brake operator to the road to proficiency. It's a long road, but it's full of challenges and fulfillment. Through continuous learning and practice, operators can stand out in this industry and become true experts. In the process, operators need to have an in-depth understanding of geometry and the ability to expertly recognize engineering drawings, as well as a strong ability to learn and adapt. Only in this way can a press brake operator gain a foothold in the ever-changing market environment, continually improve his or her skill level, and create greater value for the organization.

About Us

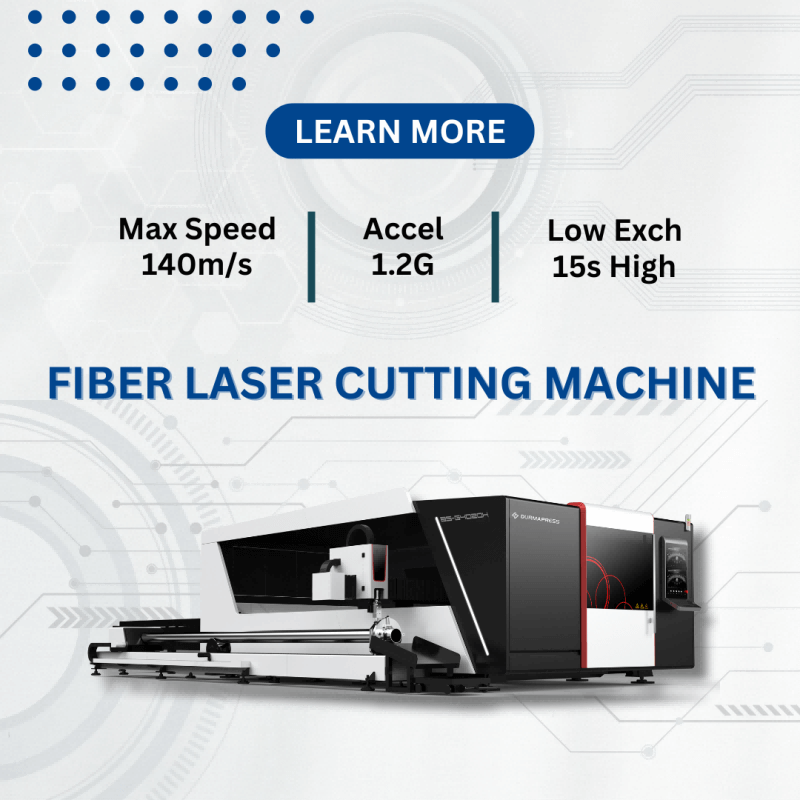

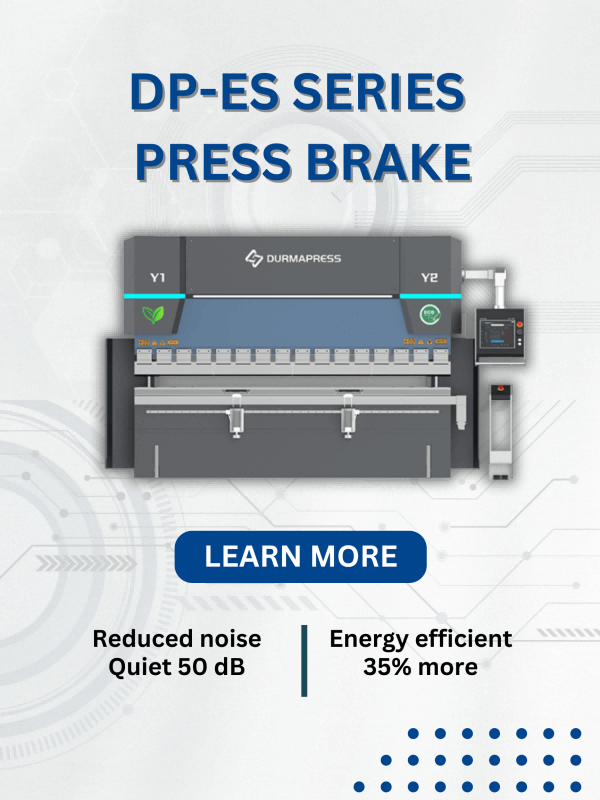

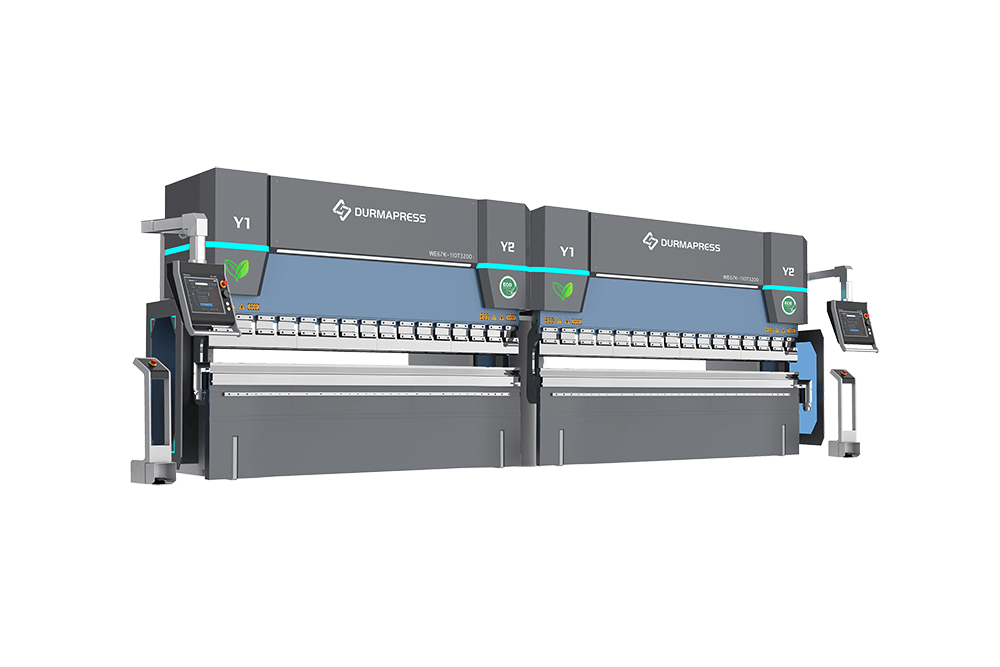

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.