Preface

A hydraulic shearing machine is a type of equipment that utilizes the motion of an upper blade and a fixed lower blade, along with a reasonable blade gap, to apply shearing force to various thicknesses of metal sheets, thereby breaking and separating the sheets into desired dimensions. A hydraulic shearing machine primarily consists of a frame, hydraulic pump, hydraulic cylinder, and blades. The frame serves as the supporting structure for the entire equipment, the hydraulic pump is a crucial component for generating hydraulic pressure, the hydraulic cylinder is the core component for generating cutting force, and the blades are essential for carrying out machining operations. It operates on the principle of transmitting pressure through a hydraulic fluid, where the hydraulic pump pressurizes the fluid and directs it into the hydraulic cylinder, generating significant pressure on the blades. This allows the machine to perform cutting and shearing operations on metal sheets. This process offers advantages such as simplicity of operation, high efficiency, and the ability to ensure machining quality and safety. Hydraulic shearing machines are classified into two main types based on the motion of the upper blade: hydraulic swing beam shearing machines and hydraulic guillotine shearing machines.

What Is A Hydraulic Swing Shear?

A hydraulic swing shearing machine is a common metal processing equipment, mainly used to cut metal sheets of different thicknesses into required lengths. It mainly consists of an upper tool holder, lower tool holder, hydraulic system, swing arm, slider, oil cylinder, and hydraulic system. The swing arm connects the upper and lower tool holders to support and transmit shear force.

What Is A Hydraulic Guillotine Shear?

A hydraulic Guillotine shearing machine is a common metal processing equipment, mainly used to cut metal sheets of different thicknesses into metal parts of required shapes and sizes. The hydraulic Guillotine shearing machine adopts an all-steel welded frame structure with hydraulic preload. It is mainly composed of the body, hydraulic system, cutting tools, fixtures, and other parts. Among them, the body is the frame of the shearing machine, the hydraulic system provides power, the cutter is responsible for shearing the metal sheet, and the clamp is used to fix the metal sheet to ensure shearing accuracy and efficiency.

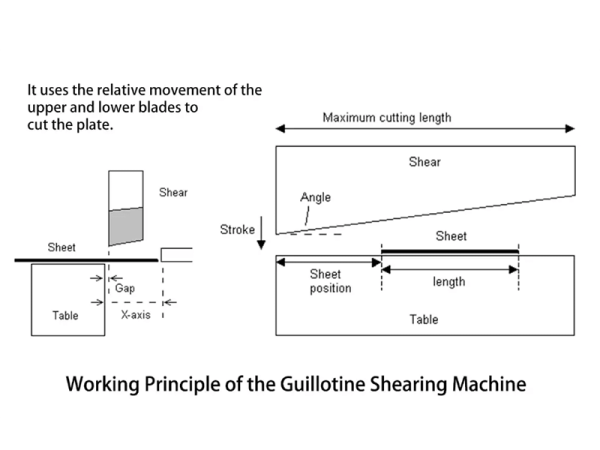

Working Principle

Hydraulic Swing Shearing Machine

The hydraulic swing shearing machine is driven by hydraulic pressure and uses an oil cylinder to push the swing shearing mechanism to achieve shearing of the plate. When the oil cylinder pushes the blade of the shearing mechanism toward the plate, a huge pressure is generated between the blade and the plate, causing the plate to reach shear strength, thereby achieving shearing.

Hydraulic Guillotine Shearing Machine

The working principle of the hydraulic Guillotine shearing machine is to provide power through the hydraulic system to push the cutter downward to shear the metal plate. During the shearing process, the clamp between the cutter and the metal sheet secures the metal sheet to prevent it from moving or bending. The hydraulic system uses a two-way cartridge integrated valve; the entire system uses a digital stroke display, a photoelectric protection device, and a mobile workbench (to facilitate mold replacement). Function, the working pressure stroke can be adjusted within the specified range according to process requirements, and the buttons are centralized for easy operation.At the same time, the hydraulic system can also control the down force and shearing speed of the tool by adjusting pressure and flow to achieve different shearing effects.

Shearing Machine Performance Characteristics

Hydraulic swing shearing machine

- The hydraulic transmission ensures that the thickness of the sheet will not change during operation. In addition, this machine has the characteristics of smooth operation, convenient operation, low noise, safety, and reliability.

- There is a mechanical stop in the oil cylinder to ensure the repeatable positioning accuracy of the slider to the bottom dead center to ensure the consistency of the bending angle during mass production.

- Use German technology for internal stress relief.

- The overall frame is rust-removed by sandblasting and sprayed with anti-rust paint.

Hydraulic Guillotine shearing machine

- The vibration of the frame and tool holder eliminates stress, and the whole machine is welded and durable.

- Advanced integrated hydraulic system with good reliability.

- Use a three-point supporting rolling guide rail to eliminate supporting gaps and ensure shearing quality.

- The blade gap can be adjusted manually or electrically, quickly and accurately.

- The upper and lower blades adopt four-sided blades to increase the use time and extend the service life of the blades.

- The shearing angle can be adjusted electrically to minimize the deformation of the plate.

- It has the function of segmented fixed-length cutting.

- Automatic filling function.

- Electric back gauge and digital display, accurate and reliable.

- The shearing end surface, shearing speed, and shearing thickness are superior to those of hydraulic swing shears of the same specifications.

Adaptation system

Hydraulic Swing Shearing Machine

DELEM DAC-310T CNC Controller System

The Dutch company DELEM produces imported DAC-310T CNC controllers for metal plate-cutting machines. It features a high-definition LCD with a resolution of 1024 × 600 pixels and 100-step programming. It adopts professional servo control technology and full touch screen control, which greatly improves cutting accuracy.

Hydraulic Guillotine Shearing Machine

The DAC-360T CNC system of the shearing machine is imported from the Netherlands and produced by DELEM. It is equipped with a high-definition LCD panel and, a built-in time relay, and also has one-key switching and unilateral positioning functions. Using X-axis intelligent positioning, multi-step programming of 40 programs, each program has 25 steps. It can automatically calculate shearing pressure, automatically control back gauge, shearing stroke, shearing angle, blade gap, and flexibly define I/O ports.

Common Adaptation System

ESTUN E21S CNC System

This E21S CNC system with a high-definition LCD has many great features. Users can choose Chinese and English languages, and the programming parameters are clear at a glance, which improves the efficiency and convenience of programming. The back gauge system has intelligent positioning and also supports manual adjustment, eliminating the need for a mechanical manual positioning device. The built-in shear time relay simplifies the operation of the shear stroke and saves costs. In addition, the built-in cutting angle adjustment function eliminates the tedious operation of angle indicators and buttons. The encoder feedback displays the knife edge gap in time, making the operation easier. It also has one-click parameter backup and recovery functions, which can restore parameters at any time as needed, reducing maintenance costs. All buttons on the panel use micro switches and undergo strict EMC, high and low temperature, and vibration tests to ensure the stability and service life of the product.

The main differences between Guillotine shears and swing shears

Cutting Accuracy

The knife rest of the swing shearing machine itself is arc-shaped, and the point contact of the arc ensures the straightness of the material being sheared, while the knife rest of the Guillotine shearing machine operates relative to the lower blade. Vertical linear motion ensures small deformation and good straightness of the sheared plate. Therefore, in comparison, the hydraulic Guillotine shearing machine is more accurate than the hydraulic swing shearing machine.

Taking the 16*3200 hydraulic swing shearing machine and the hydraulic Guillotine shearing machine as an example, the gap values calculated at the edges of the swing and Guillotine shearing machines are both less than 6 mm, but the gap between the swing arm and the swing frame body of the swing beam machine is The bearing connection gap between them cannot be eliminated.

In addition, the cumulative shearing accuracy error of the gap and edge gap is generally more than 10 mm, and the rear guide rail of the Guillotine【 shear body is supported by 4 large bearings, and the front guide rail is pressed behind them by 2 bearings with compression springs. Tight, so that there is no gap between the front and rear guide rails, and the additional precision error between the gap and the edge gap is kept below 4 mm, so the sheared material is smoother and burr-free.

Different Shear Angles

When shearing plates with a thickness of less than 20 mm, the shearing angle of the hydraulic swing shearing machine cannot be adjusted, causing the sheared material to be distorted. The narrower the material being cut, the greater the deformation. Since the shearing angle of the hydraulic swing shearing machine is fixed, the efficiency of shearing thin plates and thick plates is the same, which means that a lot of power resources and running time are required. For example: the QC12Y-10X2500 hydraulic shearing machine has a motor power of 55KW and can cut a 10mm thick plate 8 times/minute. Since the shearing angle cannot be adjusted, the same 5mm thick plate can be sheared 8 times/minute. To reduce frame deformation and reduce machine power, the shearing angle of the swing shearing machine is usually at the maximum value, but a larger shearing angle when shearing thin plates will cause greater bending deformation of the sheared work piece.

In contrast, hydraulic Guillotine shears can achieve angle adjustment by adjusting the amount of oil in a closed chamber connected in series between two engineering cylinders. During work, the curvature of the plate is effectively reduced, making the sheared plate less likely to twist and deform, thereby maintaining the accuracy of the work piece. More importantly, the shear force is stronger when the shear angle is increased.

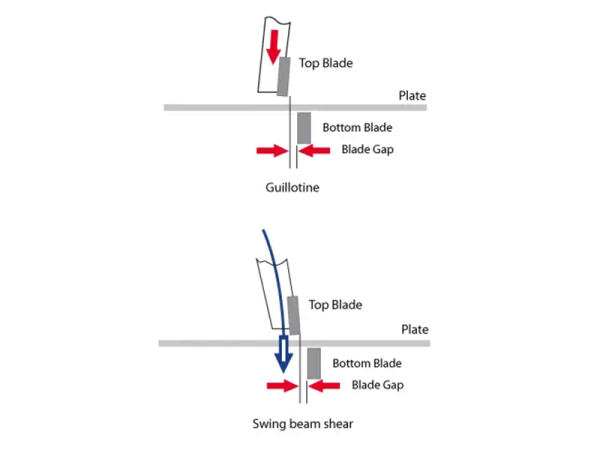

Different Types of Exercise

The blade holder of the Guillotine shearing machine moves up and down. It makes a vertical linear motion relative to the lower blade to ensure the shearing of the sheet. The distortion and deformation are small, the straightness is more accurate, and the accuracy is twice that of the swing shearing machine. The swing-type shearing machine has an arc-shaped movement. The tool holder body of the swing shear is arc-shaped, and the points of the arc are used to contact to ensure the straightness of the sheared material.

Blade Differences

Hydraulic swing shears cannot use all four edges of the blade to cut sheet metal due to the arc-shaped motion of their blades.

Therefore, only diamond-shaped cutting edges can be used for double-sided cutting.

In contrast, the blade holder of the Guillotine shearing machine moves up and down in a linear motion, allowing it to directly use a rectangular blade with four cutting edges. This makes the blade of the Guillotine shearing machine last longer than the blade of the swing shearing machine. double. In addition, the diamond-shaped blade shears the plate, which can easily cause the plate to twist. This defect becomes more severe the narrower the material you are cutting, and a rectangular blade avoids this defect.

Cylinder Life

The semicircular block of the built-in oil cylinder used in the swing shearing machine is difficult to lubricate and maintain, but the upper and lower chambers of the oil cylinder in the shearing machine project do not require additional lubrication, thus greatly extending the service life of the shearing machine. Improve service life.

Operational Differences

Since the blade holder of the swing shearing machine is arc-shaped, arc point contact is made to ensure the straightness of the material being sheared.

The Guillotine shear ensures the straightness of the material being sheared through its straight blade holder, thereby achieving higher precision.

However, there is an obvious blade retraction phenomenon in the middle of the swing-type shearing machine, resulting in burrs on some sheared materials. This problem cannot be avoided.

Application Areas

Hydraulic Guillotine Shearing Machine

Hydraulic guillotine shearing machines are widely used in metal processing industries such as automotive, aviation, machinery, and construction. They excel in efficiently and accurately shearing various metal sheets, especially in large-scale production settings. Hydraulic guillotine shearing machines have a broader range of applications and are suitable for industries such as automotive, tractors, locomotives, ships, motors, and instruments, and are also suitable for stretching high-strength alloy sheets.

For example, in a coal processing plant designed to process 3 million tons of coal annually, which later expanded to a maximum capacity of 16 million tons per year, hydraulic guillotine shearing machines play a crucial role in achieving cost savings, reducing production costs, and improving efficiency. The plant faced the challenge of optimizing its operations in the context of high-quality, intelligent development. The existing mechanical shear machine had exceeded its service life, had a high failure rate, and low efficiency, and could not meet the current processing needs. Hydraulic guillotine shearing machines were introduced to transition the processing equipment towards greater automation and efficiency, with the goal of reducing costs, increasing efficiency, and lowering maintenance expenses.

Hydraulic Swing Beam Shearing Machine

Hydraulic swing beam shearing machines are known for their high cutting precision, efficiency, and low noise. Driven by hydraulic systems, they offer precise and uniform motion, and ease of operation, and are suitable for processes like stretching, bending, squeezing, and forming thin metal sheets in industries such as power generation and aviation.

For instance, ABC Manufacturing Co., Ltd. purchased an advanced hydraulic swing beam shearing machine to replace their outdated cutting equipment. They opted for a high-performance swing beam shearing machine capable of meeting their metal sheet cutting needs, offering enhanced cutting capacity and automated control features. They seamlessly integrated this hydraulic swing beam shearing machine into their production workflow. The performance advantages of the new equipment enabled them to meet customer demands more efficiently, reduce production cycles, minimize waste, and improve product quality. This not only increased the company's competitiveness but also led to more orders and business growth. The investment in the swing beam shearing machine not only boosted production efficiency but also helped the company capture a larger market share, establishing them as leaders in the metal processing industry.

Conclusion and Usage Recommendations

In conclusion, the main differences between hydraulic guillotine shearing machines and hydraulic swing beam shearing machines lie in their machine structures and operating principles. The former uses a Guillotine-type pressure transmission mechanism, making it suitable for cutting various material thicknesses with high precision. On the other hand, hydraulic swing beam shearing machines use a swinging arm design and are not suitable for cutting thick materials, but they offer advantages such as a smaller footprint and good stability.

Furthermore, hydraulic guillotine shearing machines offer higher precision, and longer blade lifespan, and are ideal for various material thicknesses. However, their manufacturing cost is higher. Considering cost savings and precision requirements, if precision is not critical and the material thickness is thin (below 8mm), a swing beam shearing machine may be suitable. For materials exceeding 8mm in thickness, a hydraulic guillotine shearing machine is necessary, as the swing beam shearing machine's principle limits it from cutting thick materials. When making a purchase, comprehensive consideration should be given to actual needs. If you have any further questions about shearing machines, please feel free to contact DURMAPRESS!

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)