Press Brake

Definition

A press brake, as an essential metal processing equipment, is widely utilized in the bending and forming processes of various metal sheets. This article will elaborate on the definition, structure, operation, and characteristics of the press brake to assist readers in better understanding and using this equipment.

Structure

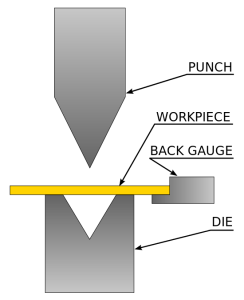

The press brake is mainly composed of a frame, a workbench, a hydraulic system, an electrical control system, and a mold. The frame serves as the support structure for the entire equipment, while the workbench acts as the platform where metal plates are placed and bent. The hydraulic system provides power for the bending operation, and this power is transmitted to the working mechanism through the transmission mechanism to achieve plate bending. The electrical control system is responsible for controlling the operation of the entire equipment, including the setting and adjustment of parameters such as working speed and bending angle. The mold is an important part of the press brake, and its shape and accuracy directly affect the quality and accuracy of the bending finished product.

Panel Bender

Definition

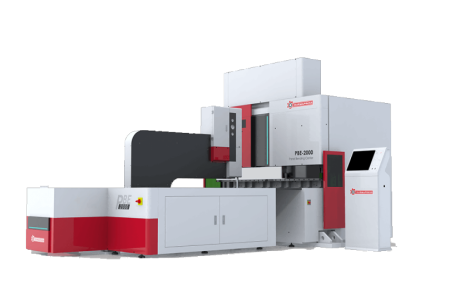

A panel bender, also known as a bending machine or plate bending machine, is a piece of equipment widely used in industrial manufacturing. Its primary function is to precisely bend metallic or non-metallic plates to meet various product design and production requirements. With its characteristics of high efficiency, precision, and reliability, the panel bender has become an essential tool in modern manufacturing.

Structure

The panel bender mainly consists of a body, a worktable, a bending mechanism, a control system, and other components. The body is typically made of sturdy steel structure to ensure equipment stability and durability. The worktable is responsible for carrying the plates to be processed, ensuring their stability during bending through precise positioning and fixation. The bending mechanism is the core part of the panel bender, accurately bending plates through precise mechanics and mechanical structure. The control system manages overall equipment operation and parameter setting, making operation more user-friendly and efficient through a humanized interface and intelligent control logic.

Operation

When operating the panel bender, the plate to be processed should first be placed on the worktable and fixed by the positioning device. Then, through the control system, set the bending angle, depth, and other parameters, and start the bending mechanism for bending operations. During the entire bending process, the control system monitors the equipment's operation status and the bending effect in real-time to ensure processing quality and precision. After the operation is completed, the bent sheet can be easily removed for subsequent processing or assembly.

Features

Efficiency: The panel bender adopts advanced mechanical structure and control system, enabling fast and accurate bending operations, greatly improving production efficiency.

Precision: Through precise positioning and control systems, the panel bender can achieve high-precision bending processing to meet various complex product design requirements.

Stability: With a sturdy steel structure and precise mechanical components, the panel bender ensures equipment stability, durability, and reduced maintenance costs.

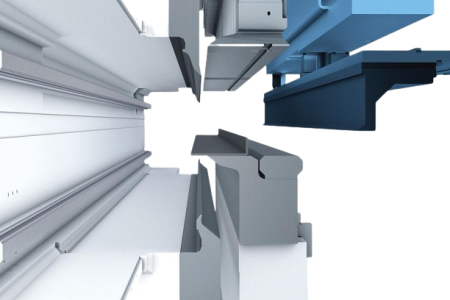

Flexibility: Suitable for processing a wide range of materials and plate specifications, the panel bender can achieve different shapes and sizes of bending needs by adjusting parameters and replacing molds.

Safety: Equipped with comprehensive safety protection devices such as emergency stop buttons and overload protection, the panel bender ensures operator safety.

Difference Between Press Brake and Panel Bender

Press Brake

Machine Structure

A press brake typically adopts a traditional C-type or gantry structure, mainly composed of a machine body, worktable, bending mechanism, and backgauge device. They are suitable for various angle bending operations on metal sheets. In contrast, a panel bender is specifically designed for processing large panels, with a typically larger and more complex structure including a large worktable, high-precision bending mechanism, and automatic feeding system.

Operation Method

Press brakes have relatively simple operations, usually completed manually or semi-automatically for sheet positioning and bending. On the other hand, panel benders often utilize fully automated operation methods, allowing for efficient and precise panel processing.

Usage Scope

Press brakes are suitable for bending processing various metal sheets, including stainless steel, aluminum alloy, carbon steel, etc. On the contrary, panel benders are more suitable for processing large panels such as architectural curtain walls, solar panels, etc.

Accuracy and Repeatability

Due to the specific characteristics of panel benders in structure, operation methods, and usage scope, they generally excel in accuracy and repeatability compared to press brakes. Panel benders can achieve higher precision panel processing and maintain stability in multiple repeated processes.

Production Efficiency

Panel benders typically have higher production efficiency than press brakes due to their fully automated operation. They can complete a large number of panel processing tasks in a shorter time, thus improving production efficiency.

Panel Bender

Production Speed

The production speed of a panel bender affects the efficiency of the entire production process. Fast panel benders can quickly process a large number of panels, increasing production output.

Panel Positioning Accuracy

Panel benders require precise panel positioning to ensure accurate bending positions every time. Efficient panel benders can accurately position panels, avoiding waste and rework.

Ease of Operation

The operation interface of a panel bender should be designed to be simple and easy to understand for convenient operation. A user-friendly interface and intelligent control system help operators quickly adapt and improve operational efficiency.

Cost and Investment

Due to the advantages in structure, precision, and efficiency, panel benders usually have higher costs and investments compared to press brakes. However, for enterprises requiring the processing of large panels, investing in a panel bender can bring higher production efficiency and product quality, leading to better economic benefits.

Future Demand

With the continuous development and technological progress of the manufacturing industry, the future demand for press brakes and panel benders will show different trends. The demand for press brakes will continue to grow as the metal processing industry develops rapidly. On the other hand, with the rapid development of industries such as construction and new energy, the demand for large panel processing equipment will also increase. Therefore, panel benders will have broader market prospects in the future.

Limitations

Press Brake

The operation of the press brake is cumbersome and requires a large amount of manpower and auxiliary equipment.

This equipment is complex to operate and requires a significant investment in human resources and auxiliary equipment support. Employees need to receive specialized training to master correct operating skills and safety procedures. At the same time, auxiliary equipment such as clamps and molds is also indispensable, increasing the complexity and difficulty of the operation. These factors jointly lead to an increase in labor costs during the production process, posing challenges to the company's production management and cost control.

For complex products such as electrical cabinets, the production efficiency of the press brake decreases significantly. These products usually have multiple bending angles and different size requirements, which require frequent adjustment of the press brake parameters and processes during production. This not only increases the production cycle but also leads to a decrease in production efficiency. At the same time, due to the complexity of the operation and adjustment, the possibility of errors also increases, which will further extend the production cycle, increase production costs, and waste resources.

Panel Bender

Panel bender are generally suitable for thinner metal sheets and may have limitations for thicker sheets.Certain specific materials (such as high-strength steel) may not be suitable for panel bending and require the use of a press brake.

The panel bender has limitations in terms of larger sizes, as its bending length and width may be restricted, making it more suitable for smaller-sized components. When dealing with large or specially shaped components, the utilization of a press brake may be necessary due to the complexity and uniqueness of their shapes, which may exceed the capabilities of the panel bender.

Summary

In conclusion, there are significant differences between press brakes and panel benders in terms of structure, operation method, usage scope, accuracy and repeatability, production efficiency, cost and investment, and future demand. When choosing equipment, enterprises should select the appropriate type based on their production needs and processing requirements.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)