Metal presses play a significant role in the metal working industry. They are used to change the shape, size or properties of metal materials by applying pressure, and are widely used in a variety of applications, including automotive, aerospace, construction, electronics and electrical appliances. As technology continues to advance, metal presses are becoming increasingly diverse to meet different processing needs. The purpose of this article is to introduce several common types of metal presses, including mechanical, hydraulic, pneumatic, CNC, and composite, and discuss their definitions, characteristics, and application scenarios.

Mechanical Metal Presses

Definition

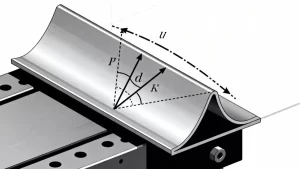

Mechanical metal press is a kind of mechanical equipment that utilizes the rotary motion of flywheel and crankshaft as the power source, and changes the rotary motion into linear motion through the efficient conversion of connecting rod mechanism, thus exerting high-intensity pressure on metal materials. It ensures that the pressure can be evenly distributed during the processing of metal materials through precise mechanical structure design, thus realizing plastic deformation of metal materials to achieve the required shape and size.

Features

- Simple structure, easy maintenance.

- Stable operation, suitable for mass production.

- Low cost, suitable for small and medium-sized enterprises.

Application

In actual production, mechanical metal press is widely used in various metal materials stamping, shearing, molding and other processing processes. For example, in the automobile manufacturing industry, it is commonly used in the manufacture of automobile body parts, such as doors, wings, engine covers and other key parts of the stamping production. In addition, it also plays an important role in industries such as home appliances, hardware, and electronics, helping these industries to realize efficient and precise metal processing needs.

Hydraulic Metal Presses

Definition

Hydraulic metal press, it is a kind of equipment that adopts liquid as the working medium, and utilizes the incompressibility of liquid and the principle of hydraulic transmission to realize energy conversion and mechanical operation. Through the hydraulic pump, the pressure energy of the hydraulic fluid is efficiently converted into mechanical energy, and then various processing treatments are carried out on the metal materials, such as molding, pressing, bending, tensile and so on.

Features

- High pressure and adjustable stroke, suitable for processing large or heavy workpieces.

- Higher precision, can realize the processing of complex shapes.

- Low noise, low vibration and friendly working environment.

Application

This equipment is widely used in the forging industry because of its high efficiency, precision and stable processing capability. It can not only be used for die forging, but also for free forging, and it is also handy for calibrating and equalizing processing of plates. Especially in those production occasions that have high requirements for pressure tonnage and strict standards for processing accuracy, hydraulic metal presses have shown their excellent performance and irreplaceable role. Whether in the field of aviation, aerospace, automobile, ship or other metal structure manufacturing, it is one of the important equipment to ensure product quality and efficiency.

Pneumatic Metal Press

Definition

A kind of metal press that utilizes compressed air as its power source, which efficiently converts the pressure energy of the gas into mechanical energy through the cylinder, to process all kinds of metal materials, to meet the demand for metal parts forming in industrial production.

Features

- Simple structure, light weight, easy to move and install.

- Low cost, easy to operate, suitable for small-scale production and maintenance operations.

- High safety, when overload and other abnormal conditions occur, the machine can stop automatically, effectively preventing the equipment from being damaged due to overloading and prolonging the service life of the equipment.

Application

Commonly used in riveting, punching, assembly and other lightweight metal processing tasks. Its high efficiency, stability and reliability make it the right hand of the metal processing industry.

CNC Metal Press

Definition

CNC metal press is a high-tech product that integrates high-end CNC technology into press equipment. Through precise programming, it can control various actions of the press, thus realizing automated, high-precision processing of metal materials. This kind of equipment not only has high efficiency, but also has high stability, which is an indispensable and important equipment in modern manufacturing industry.

Features

- High processing precision and good repeatability.

- High degree of automation, reduce manual intervention, improve production efficiency.

- Strong programmability, adapt to a variety of processing needs.

Application

CNC metal press has a wide range of applications in precision manufacturing, aerospace, electronics and electrical appliances. It is mainly used for processing those metal parts with complex shapes and high precision requirements, and is an indispensable key equipment in these fields.

Compound Metal Press

Definition

A composite metal press is an innovative machine that integrates the advantages of multiple types of presses. For example, it combines mechanical presses with hydraulic presses, CNC technology with pneumatic technology, and so on, to achieve more flexible and efficient metal processing.

Features

- Versatile and adaptable to meet different processing needs.

- High efficiency, can complete a variety of processing tasks on the same equipment.

- The cost is relatively high, but in the long run can reduce the comprehensive cost.

Application

Compound metal press is suitable for those complex metal product production lines that require multi-process, high-efficiency and high-precision processing. It can play a powerful role in these production lines, helping enterprises to improve production efficiency and reduce production costs.

Summarize

Product Characteristics

In the field of metal processing, metal presses are crucial equipment, and they play a key role in forming and deforming metal materials through mechanical force in the manufacturing process. There are a wide variety of presses, each with its own unique technical characteristics and application scenarios, thus meeting the diverse needs of different production requirements.

Mechanical presses, which rely on mechanical structures to transmit pressure, are a traditional and widely used type. They are usually characterized by simple structure and easy operation, and are particularly suitable for industrial situations requiring mass production. Due to their stable performance and low failure rate, mechanical presses are the preferred choice of many manufacturers, especially in production lines where the pace of production is fast and continuous operation is required.

Hydraulic presses, on the other hand, utilize a liquid as the working medium to drive a ram through a cycle of pressurized oil for stamping. This type of press has a large tonnage capacity and is able to cope with the processing needs of large and heavy workpieces, and is also suitable for occasions that require extremely high processing accuracy. Hydraulic presses, because of their excellent controllability and adaptability, occupy an important position in the manufacture of precision parts in the aerospace and automotive industries.

Compared to the first two, pneumatic presses utilize compressed air as a power source, which makes them simpler in structure, smaller in size, lighter in weight, and easier to move. This makes pneumatic presses ideal for small and medium-sized businesses and maintenance sites that require flexibility, and they perform particularly well in small-scale production or rapid prototyping.

With the development of technology, CNC (numerical control) presses have emerged, which are controlled by a computer numerical control system, enabling not only high-precision machining, but also automated production. This highly intelligent equipment excels in areas such as precision mold manufacturing and high-precision parts processing, and is an important tool for modern manufacturing to improve product quality and efficiency.

Compound presses, on the other hand, integrate the characteristics of a variety of presses, with the processing capability of large-scale equipment and the high precision and operational flexibility of small-scale equipment. This versatility and high efficiency makes compound presses show strong advantages when dealing with complex machining tasks, and they are able to meet a variety of different machining needs, so they have been widely used in the modern manufacturing industry.

Selection

When choosing a metal press, it is necessary to make a comprehensive consideration according to the actual production and processing needs, as well as budget and other conditions. First of all, it is necessary to clarify the type of material to be processed, the shape to be achieved, dimensional accuracy and surface quality and other requirements, and then according to these requirements to compare the performance and characteristics of different types of presses, so as to choose the equipment that best meets their needs. At the same time, the reliability of the equipment, the quality of after-sales service and the availability of spare parts are also factors that must be taken into account in the selection process, as they will have a direct impact on the efficiency of the equipment and the continuity of production. By doing so, we can ensure that the selected metal presses can maximize their effectiveness in the actual production process and create more value for the enterprise.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.