three-roller

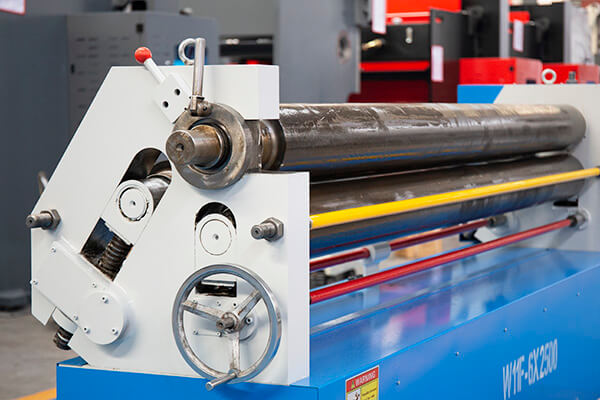

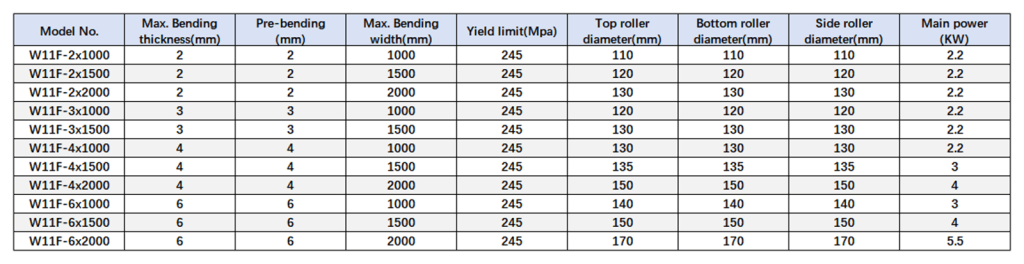

W11F Hydraulic Rolling Machine

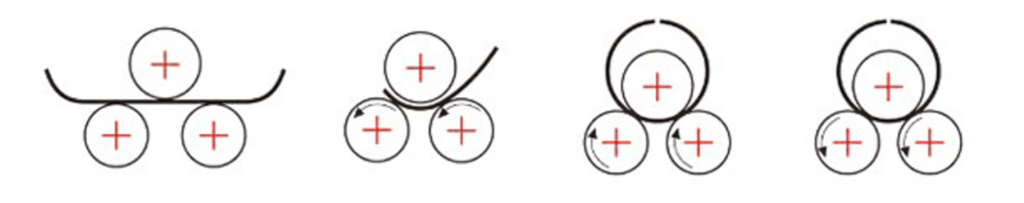

Three-roller symmetric structure driven by a screw lever and turbine worm, the upper roller moves in the vertical direction in the center symmetrical position between the lower two rollers.

Three-roller symmetric structure driven by a screw lever and turbine worm, the upper roller moves in the vertical direction in the center symmetrical position between the lower two rollers.

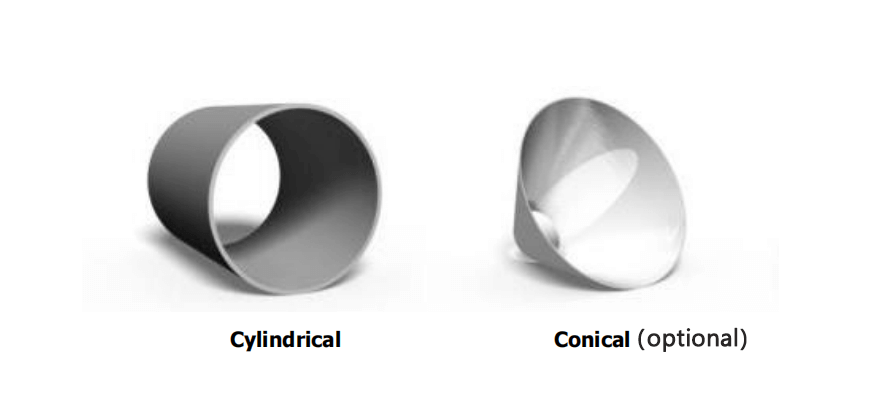

Customize your configuration according to your needs

Standard accessories for W11F Hydraulic Rolling Machine

The system uses wearing linear guides, ensuring the rolling scales do not affect the system. This planetary system operates safely with minimal maintenance and downtime, maintaining a robust body even at small rolling diameters.

The three-roll plate bending machine is a versatile and efficient tool for bending metal plates. Its mechanical design includes two lower driving rolls powered by a motor and reducer, while the upper roll is driven and controlled by a motor, reducer, worm, and gear mechanism.

The control panel is easy to operate and maintain, with an electrical cabinet meeting international CE standards, ensuring strong anti-interference capability. It is equipped with protective fences and safety interlocks to ensure operational safety, and features a flexible design with the ability to add control buttons according to needs for diverse functionality.

The bodies of DURMAPRESS Plate Rolls are designed with FEM analysis to obtain a maximum strength and rigid structure. In this way, tensions that occur during bending are minimized to provide safer and longer machine life.

Driven by a hydraulic system, the rolled products on the plate bending machine can be safely flipped to the other side for further processing or handling. The tipping device ensures that the product remains stable during the turning process, and the turning angle and speed can be adjusted as needed.

The bodies of DURMAPRESS Plate Rolls are designed with FEM analysis to obtain a maximum strength and rigid structure. In this way, tensions that occur during bending are minimized to provide safer and longer machine life.

Durmapress always adheres to the concept of putting customers first in the whole purchase experience, and continuously optimizes and innovates the production process to cater to the needs of all large, medium and small manufacturing companies.

1

Hydraulic systems provide precise control over the rolling process, ensuring accurate bending angles and dimensions.

2

Hydraulic systems can exert high levels of force, allowing for faster rolling speeds and increased productivity.

3

Hydraulic systems are known for their durability and reliability, ensuring long-term performance with minimal maintenance.

Utilizes a variable flow piston pump for high-pressure resistance, durability, and low noise. The specially designed hydraulic motor offers efficient operation with minimal power consumption and increased speed.

Features an integrated hydraulic control system from YUKUN-Japan for reliability and easy maintenance. Includes overload overflow protection for leak-free operation and direct oil level monitoring. Compliant with Directive 98/37 EC.

The electrical cabinet meets IP65 standards and is CE certified, ensuring safety and reliability with strong anti-interference capabilities. Equipped with protective fences, safety interlocks, and a movable single-hand pedal switch for easy operation.

Front side covers include safety switches, backlight safety guards (Category-4), and a foot pedal conforming to CE regulations for enhanced safety during operation.

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

7/24

Fill in the information below to receive a free quote and product brochure. We will respond within 24 hours!