quote

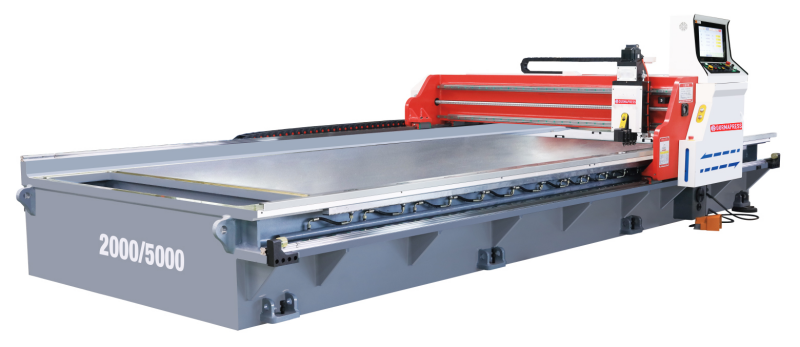

In today's manufacturing industry, V-type tank machine production is an important processing equipment, which is used for various types of metal and non-metal material processing areas. The main function of the V-shaped tank machine is that it has a specific cutting tool, and the V-shaped tank mouth is formed according to the existing construction, so that it is fully equipped with specific equipment or functional requirements. The basic processing method is different in terms of structure and features, and the V-type tank machine can be separated into two different types: Vertical V Groover Machine machine and Horizontal V Groover Machine machine. The main text of this article is a detailed explanation of the operation of each type of equipment, and the following information is provided by the relevant industry personnel for reference.

Vertical V Groover Machine

fixed and given special points

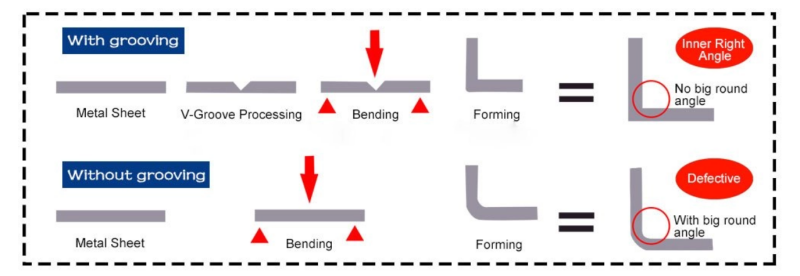

We have in-depth research in precision iron manufacturing industry, the most outstanding new product is V-type opening machine, its core is V-type opening machine, usually also called V-type opening machine, which is unique and powerful. Tools, precision manufacturing items. Is this important? In the metal processing field, the concave tank's precision and depth directly affect the final product's bendability and quality.

This small device corresponds to the principle behind it, but it is very effective. The machine uses a rotary cutting tool to carve a "V" shaped recessed tank on a metal plate, and the depth and angle of the recessed tank can be carefully controlled, making it possible to make a precise curve. The various types of engineering do not require high curvature precision, and can be formed at a fixed angle, while the construction metal processing and high-end cutting, etc. are carried out in addition.

excellence

Large cutting depth, vertical V-shaped tank machine, horizontal type with larger cutting depth, suitable for progressive processing of thick materials.

High stability, horizontal placement of the work table, no material movement during machining, and excellent process stability.

However, this product is designed with attention to detail, durability, and accuracy. Usually, the main parts of the frame are made of high-grade steel or iron, and the structure is reduced in design and movement during the operation process. This is a matter of safety and stability for mechanical design. Convenient method to ensure

limitation

Materials with high hardness requirements: Materials with high hardness can be used for Japanese knives.

Cutting depth limit: Yuyu equipment structure limit, cutting depth possible limit.

Horizontal V Groover Machine

fixed and given special points

The horizontal V-shaped tank machine is equipped with a variety of metal processing machines, and its main function is to process the V-shaped tank on metal sheets. Various types of equipment used in the control technology, continuous advance setting process, number control tool operation, practical precision, consistent V-shaped tank processing. The advantages of the horizontal CNC tank machine are easy to operate, high processing precision, and efficiency, and can be used to process various types of metal plate materials. excellence

Low operator requirements: Operation horizontal CNC V-type tank machine requires no personnel equipment, and high skill requirements, easy to cultivate.

excellence

Low operator requirements: Personnel operating a CNC V-groove machine do not need to have excessive skill requirements and are easy to train and take up positions.

During V-groove processing, the user does not need to move the steel plate and will not scratch the surface of the plate, making the operation more convenient.

After processing, it is simple and convenient to clean up the waste materials, which improves work efficiency.

The horizontal V-groove machine has a relatively low price and high cost performance, making it suitable for users with limited budgets.

For decoration manufacturers, the horizontal V-groove machine is a good choice and can meet the processing needs of decoration materials.

limitation

It is only suitable for processing plates with a thickness less than 3 mm, and cannot meet the needs of thicker plates.

Due to structural limitations, the horizontal V-groove machine may be slightly inferior to the vertical type in terms of processing accuracy, and is not suitable for processing occasions that require higher accuracy.

For users who need to process large-size plates or thicker plates, the processing range of the horizontal V-groove machine is limited, so you need to choose carefully.

Application examples

Manufacturing applications

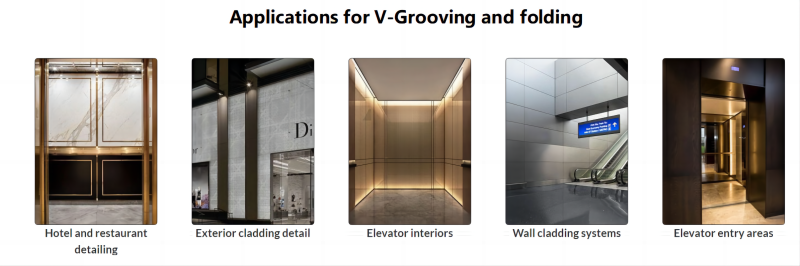

Vertical V-groove machines are often used in manufacturing industries where high processing accuracy is required, such as manufacturing precision parts, metal casings, precision instruments, etc. Its vertical design allows for better control of cutting angle and depth during processing, thereby ensuring product quality and assembly accuracy. In addition, vertical V-groove machines are generally suitable for fine machining and engraving of material surfaces.

Application in building decoration field

In the field of architectural decoration, horizontal V-groove machines are often used to cut V-grooves on building materials, such as processing aluminum plates, stainless steel plates, etc. Due to its large processing depth and ease of operation, horizontal V-grooving machines are a common choice for decorative manufacturers.

Vertical V-groove machines are also used in the field of architectural decoration. They are especially suitable for fine processing and engraving of architectural decoration materials, such as the production of exquisite metal carved panels.

Summarize

In manufacturing, vertical V-groove machines are usually used where high processing accuracy is required, while horizontal V-groove machines are suitable for processing materials of large size and thickness. In the field of architectural decoration, horizontal V-groove machines are often used for processing large materials, while vertical V-groove machines are suitable for fine processing and engraving of materials. Choosing the right machine depends on specific processing needs and material characteristics.

Comparison of vertical V-grooving machine and horizontal V-grooving machine

In contrast, horizontal V-groove machines are more suitable for processing larger sizes and thicker materials. In terms of performance, vertical V-groove machines have advantages in processing accuracy, while horizontal V-groove machines are better at processing materials of large size and thickness.

In terms of cost, although the price of the vertical V-groove machine may be slightly lower than the horizontal type, the specific cost depends on factors such as machine specifications and brand.

In terms of operation and maintenance, the vertical V-groove machine is relatively easier to operate and maintain, while the horizontal type may be more convenient when handling large-size materials.

Therefore, when choosing a vertical V-groove machine or a horizontal V-groove machine, a comprehensive evaluation needs to be based on specific processing needs, material characteristics, and budget to ensure that the selected machine can best meet production and processing needs.

conclusion and suggestion

In summary, vertical V-groove machines and horizontal V-groove machines each have unique characteristics and play an important role in different processing needs and industrial application scenarios. When higher machining accuracy is required, especially micro-machining of small parts, vertical V-grooving machines are the ideal choice, while horizontal V-grooving machines are suitable for processing large and thick plates.

When choosing the right V-groove machine, you need to consider your processing needs, material characteristics, budget, and technical capabilities. At the same time, it is particularly important to make recommendations on the selection and use of both machines based on the needs of different industries and applications. By strengthening machine operation training and maintenance, production efficiency and product quality can be effectively improved.

Therefore, when purchasing and using a V-groove processing machine, you must fully understand the company's processing needs, choose a model that suits the company, and perform daily maintenance and management of the machine to ensure smooth production and processing.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.