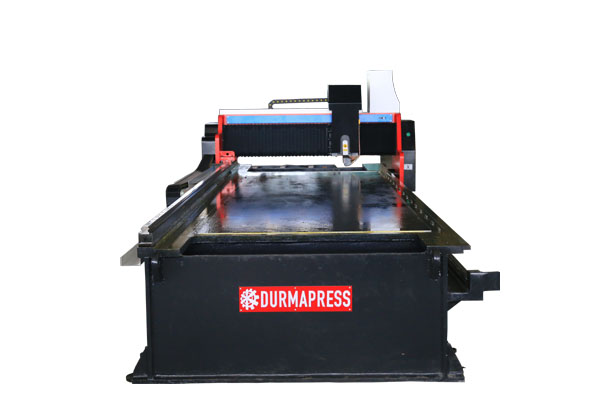

V GROOVING MACHINE

General Features

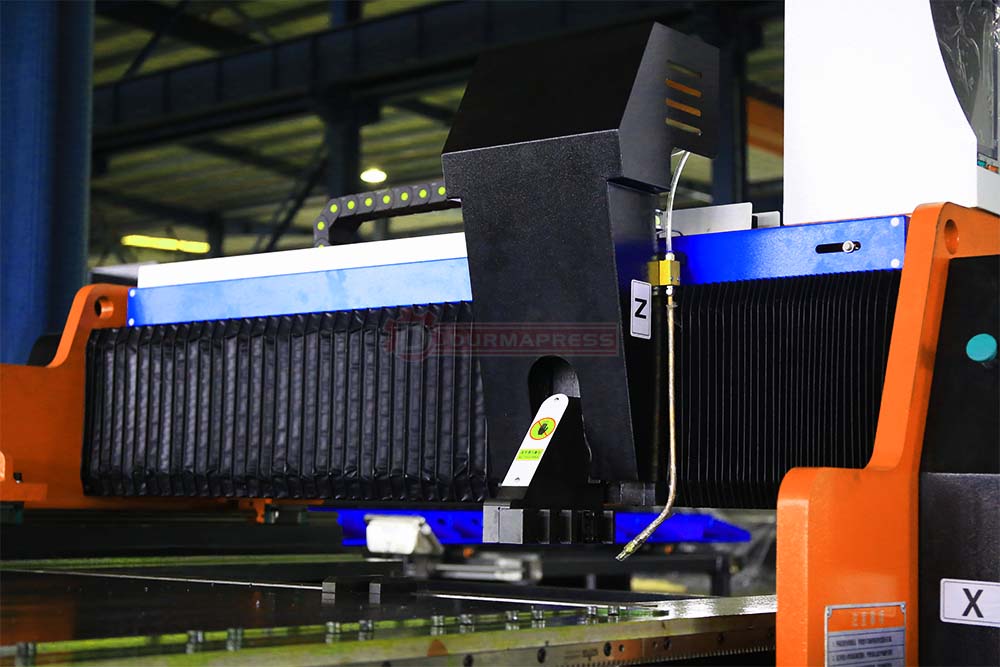

Convenient materials loading and unloading. Air cooling without environment pollution. 3+1 axis CNC servo control to realize fully automatic operation.

High pressure, reliable firmly tight force, low noise and small energy consumption. Adopt tin bronze helical gear made by #45 forging steel.

QH silent guide rail transmission, the movement speed can be adjusted. The worktable has self-healing function. NC program design.

- 3+1 axis CNC servo control

- QH silent guide rail

- self-healing worktable

STANDARD COMPONENTS

- CNC system - Japan

- Hydraulic system - Taiwan

- Frequency converter - Mitsubishi

- Servo motor - Mitsubishi

- Seal ring - VALQUA,Japan

- Motor - SEW

- Air switch - Schneider

- Contactor - Schneider

- Breaker and button - Schneider

- Relay - Schneider

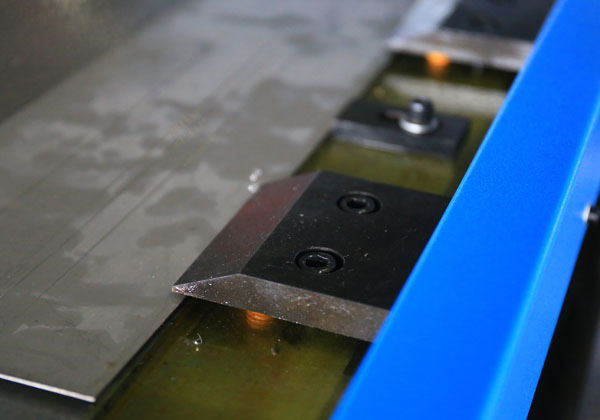

- Blades - KORLOY,Korea

- Linear guide - HINWIN, Taiwan

- Wire - IGUS, Germany

OPTIONAL

Blade with different material for cutting mild steel, brass, aluminum etc.

Would you like the brochure ?

Check out the technical data sheet and machine details in our brochure

Frame And Beam

The bed and beam of V grooving machine are all designed with the frame structure and the working table is made of 60mm low-alloy high-strength structural steel while the frame is made of Q345 steel, which make it not only rigid but also durable.

Body

The bed of V grooving machine adopts natural gas tempering to eliminate welding stress and reduce equipment deformation. Through the sandblasting treatment to ensure a good paint coating effect.

Punching station

The large punch bed area has a removable front block and is designed to give a very wide range of punching applications. A punch table with rules and guides for repetition work are fitted as the standard machine.

OTHER COMPONENTS

Write us today

Write us today and our experts are ready to help. You can contact us by the contact form below or write us email or make a phone call!