Using the method of plate shearing machine:

1. Before starting the machine, the upper and lower blades should be calibrated, and the material retaining device should be adjusted, and the work can start after the air cutting 2-3 times.

2, the gap between the blade should be determined according to the thickness of the shear steel plate, not more than 1/30 of the thickness of the steel plate.

3. The shear material shall meet the requirements and shall not exceed the limit.Prohibit shearing bar, quenching and high performance materials.

4. A plate shearing machine is not allowed to shear two materials at the same time, and it is not allowed to stand behind the material.When feeding, fingers should be away from the opening 20 cm, small pieces to use special tools.

5, when operating, to concentrate, always pay attention to whether the scissors and screws are loose.

6, the bed surface is not allowed to put tools, work pieces, etc., the cut iron scraps should be stopped in time to clean.

7. When more than two people work, they need to cooperate with each other and keep pace with each other, and there is a special person to control the shear switch.

8, do not cut the folded billet.

9. After the work is finished, cut off the power supply and lock the switch box.

10, plate shearing machine must be set up special management, strengthen maintenance.

About Us

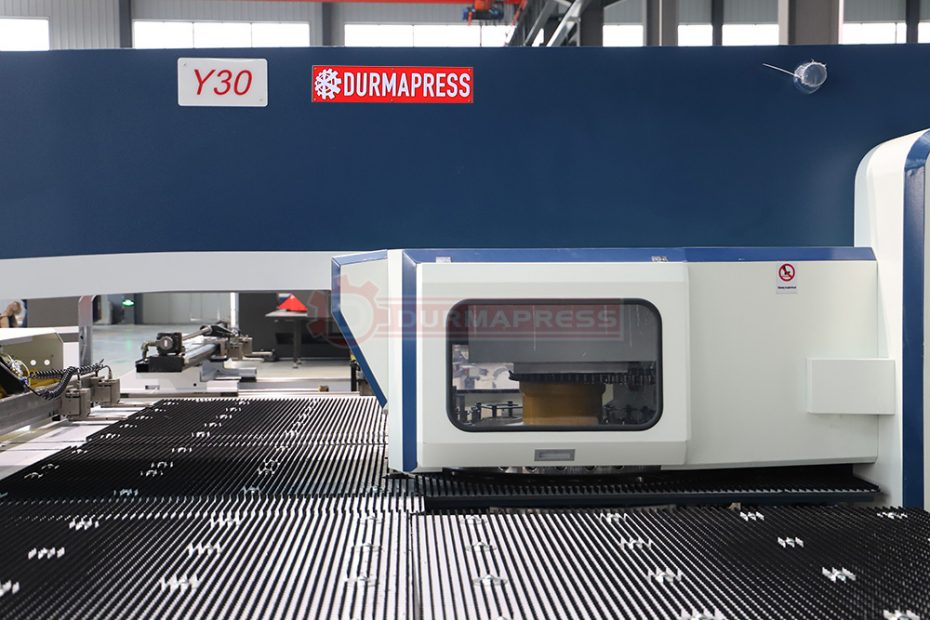

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Categories

Follow Us

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.