Introduction

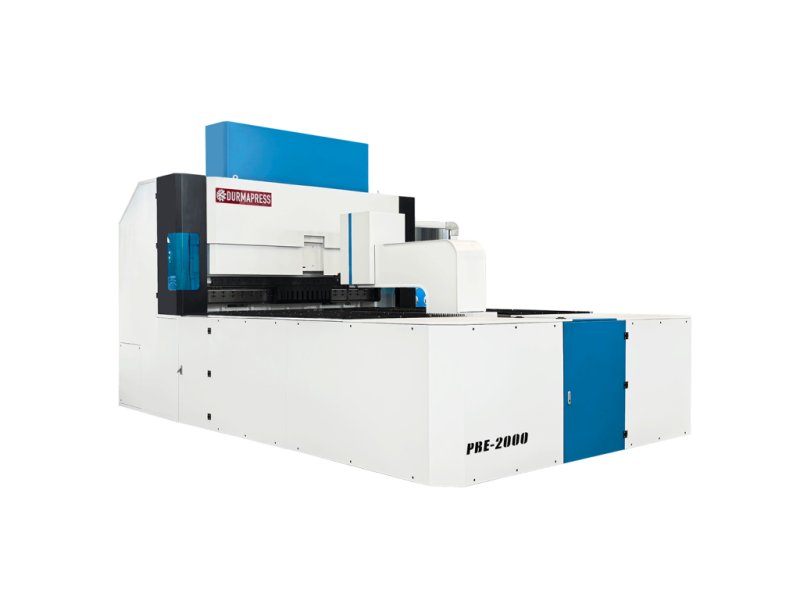

In modern industrial production, Panel Benders play a vital role as a kind of efficient and accurate metal processing equipment. So, what exactly is a Panel Bender? Simply put, a Panel Bender is a kind of automated equipment specially used for metal plate bending processing, which integrates feeding, positioning, bending, unloading and other processes, and can realize high-efficiency and high-precision metal plate processing.

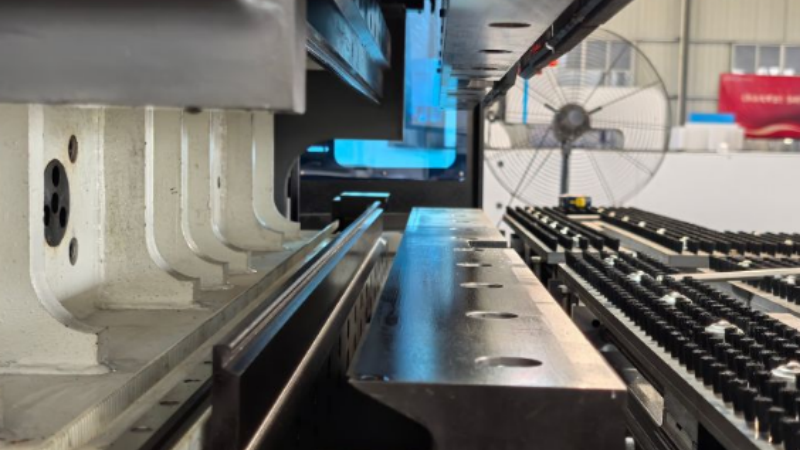

Next, we will discuss in detail the working principle of the Panel Bender and its unique advantages. The working principle of the Panel Bender mainly depends on its precise mechanical structure and advanced control system. First of all, the sheet metal to be processed enters the Panel Bender through the automatic feeding system, and then is accurately positioned by the high-precision positioning device. After the positioning is completed, the bending device starts to work and bends the sheet by means of hydraulic or electric drive. After the bending is completed, the unloading system will automatically discharge the processed plate, the entire process without human intervention, greatly improving production efficiency.

The advantages of the Panel Bender are mainly reflected in the following aspects

- high efficiency: Panel Benderthrough automated operation, to achieve a fully automated production from feeding to unloading, greatly reducing the production cycle and improve production efficiency.

- High precision: the Panel Benderadopts high-precision positioning device and advanced control system, which can ensure the accuracy of bending angle and position, thus improving the processing quality.

- Saving labor costs: Due to the fully automated operation of the Panel Bender, the dependence on labor is reduced, thus effectively reducing labor costs.

- High safety: Panel Benderin the operation process without direct human involvement, to avoid safety accidents caused by improper operation, improve production safety.

- Strong adaptability: Panel Bendercan adapt to different thicknesses and materials of metal plates, has a wide range of applications.

In short, the Panel Bender as an efficient and accurate metal processing equipment, in modern industrial production has an irreplaceable important position. Through an in-depth understanding of its working principle and advantages, we can better utilize this equipment to improve production efficiency and product quality.

Second, customer type analysis

The advantages of the Panel Bender are mainly reflected in the following aspects

These customers are suitable for high-frequency, high-volume production tasks. They have high requirements for production efficiency and automation levels to ensure that they stay ahead of the competition in the market. These types of enterprises are usually involved in mass-production industries such as automobile manufacturing and home appliance manufacturing, which require efficient production lines and highly automated equipment to meet market demand.

Precision Machining Industry

Customers in this category demand the highest level of bending accuracy and need to maintain high levels of precision and consistency in the production process. These companies are usually involved in industries such as aerospace and electronics, which have strict standards for product precision and quality. As a result, they need high-precision equipment and stable production processes to meet these requirements.

Diversified production enterprises

These customers need equipment that can quickly switch between different machining tasks to cope with the demands of production with small batches but a wide variety of products. They are often involved in industries such as metal products and customized manufacturers, which require flexible production lines to respond to diverse market demands. Such companies need to be able to quickly adjust production parameters to accommodate the processing needs of different products.

Businesses with high labor costs

Located in countries or regions with high labor costs, this group of companies reduces the need for labor by introducing automated equipment such as Panel Benders to increase the automation of the production process. This not only reduces production costs but also improves productivity and product quality. These types of companies often look to automation equipment to meet the challenges posed by high labor costs.

SMEs with a need for capacity expansion

Such SMEs want to increase their production capacity to cope with the expanding market demand. They plan to expand their market share, but at the same time need to control costs to remain competitive. By introducing efficient production equipment and automation systems, these companies can increase productivity and reduce labor costs, thereby increasing production capacity while controlling costs. Such enterprises usually hope to realize capacity expansion and market expansion through technological upgrading.

Detailed description of applicable industries

Sheet metal processing industry

Panel Benders are particularly suitable for the sheet metal processing industry, especially those tasks involving complex shapes and multi-bending of sheet metal parts. This type of equipment can efficiently complete a variety of high-precision bending operations to meet the industry's demand for complex sheet metal parts processing.

Machinery and Equipment Manufacturing

In the field of machinery and equipment manufacturing, Panel Benders can be used to process a wide variety of large parts such as mechanical housings and racks. These large parts often require precise bending and forming, and Panel Benders can provide stable and consistent processing quality to ensure the overall performance and reliability of mechanical equipment.

Conclusion

Summarize the types of customers who are suitable for Panel Benders

Panel Bender is suitable for companies with high productivity requirements, processing accuracy, and product quality. In particular, the demand for Panel Benders in these industries is particularly evident in sheet metal processing, machinery and equipment manufacturing, furniture manufacturing, and construction and decoration industries.

Encourage customers to choose the right equipment according to their needs

We encourage customers to choose the most suitable Panel Bender equipment according to their own production needs, processing characteristics and long-term development plans. Through an in-depth understanding of the functions and technical parameters of the equipment, combined with the actual production situation, choose the most appropriate equipment to achieve the best production results and economic benefits.

About Us

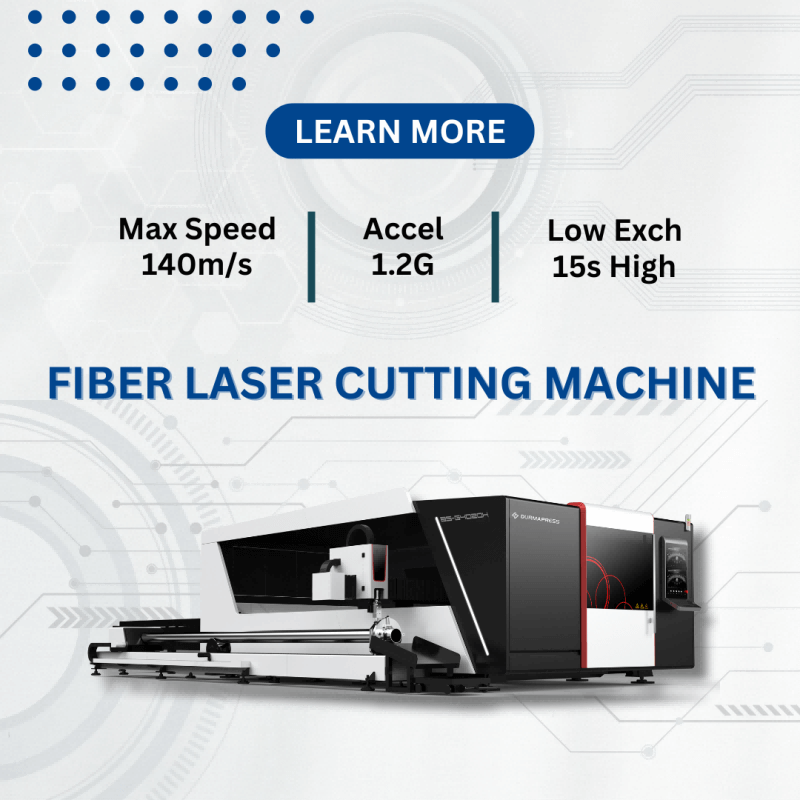

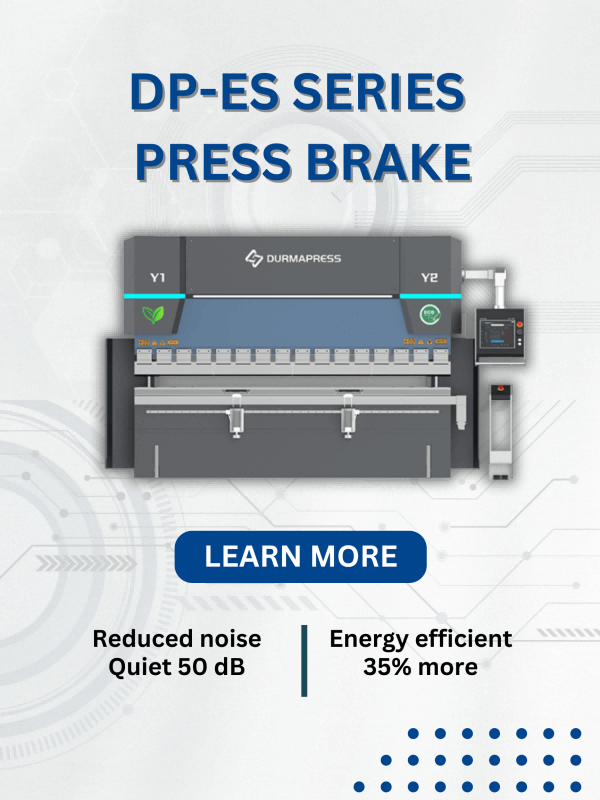

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)