Metal pipe in different application domain is widespread, the traditional processing method is to choose more cutting piece of laser cutting,

from manual to semiautomatic, then to automatic type, little imagine, because of the application field Tube laser cutting machine ,

cutting piece of laser cutting efficiency can not meet the manufacture of the current processing technology,

and many more, at this time, Laser pipe cutting machine has entered the metal pipe production Tube laser cutting machine,

processing and manufacturing industry, which provides a subversive change to the original metal pipe production, processing and manufacturing industry.

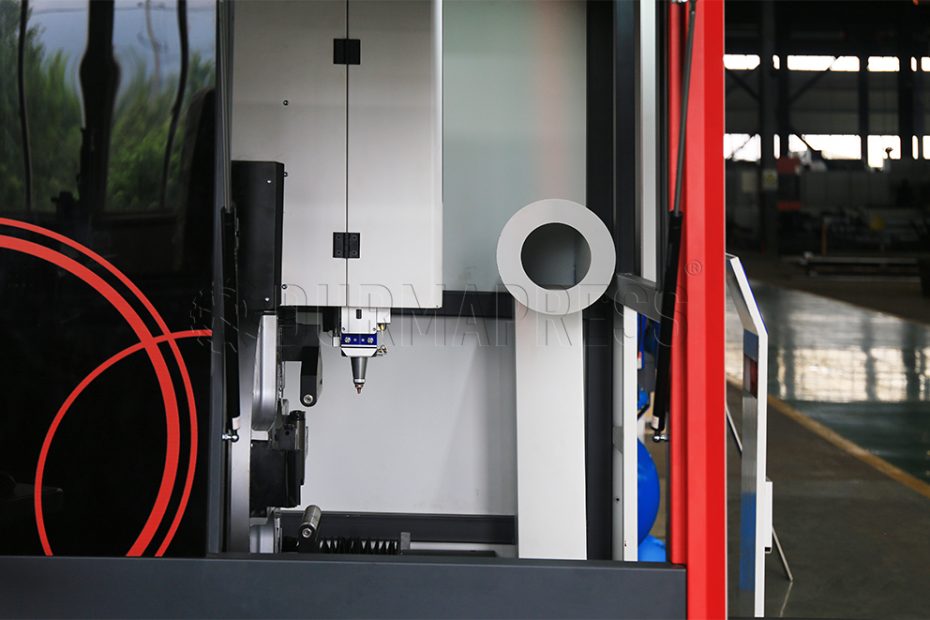

The automatic feeding, drilling, cutting Angle, beveling laser cutting and graphic drawing of laser pipe cutting

machine basically meet any needs of pipe production and processing. It is suitable for all kinds of metal pipe laser

cutting production and processing, with high automation, high efficiency, high return characteristics,

it can produce and process different shapes, different sizes of parts, in order to meet the needs of different manufacturing industries.

Pipe laser cutting machine make full use of the characteristics of laser contact production and processing,

do not damage the product workpiece, laser cutting goods without extrusion forming deformation,

production and processing out of the product quality is good, no burrs, save a lot of unnecessary production and processing process,

save the labor cost, in addition, Laser cutting machine production and processing metal pipe without mold production,

no mould cost, don't need to repair and replacement mold, can save a lot of mould application,

save production cost, reduced the cost, so, in view of the metal pipe production and processing manufacturing industry,

laser cutting machine manufacturers choose a component is critical,

Laser pipe cutting machine can not only help manufacturing enterprises to produce better goods,

but also help manufacturing enterprises to control costs and improve profits