Fiber Laser Cutting Machine -Open Type

General Features

The plate and tube integrated laser cutting machine, also known as the plate and tube dual-purpose fiber laser cutting machine, can cut both plates and tube profiles (including square tubes, round tubes, channel steel, angle steel, etc.), and can cut carbon steel and stainless steel. One machine with multiple functions, high cost performance. The bed adopts cast iron bed, rack and pinion transmission system, professional pipe cutting CNC system, with high precision, complete functions, convenient use and simple operation. The plate and tube dual-purpose fiber laser cutting machine is suitable for comprehensive processing and manufacturing enterprises.

The BS3015-1000/1500/2000/3000/4000/6000w laser cutting machine is a tube-sheet integrated machine, which can cut 3000mm×1500mm (4000mm×1500mm, 6000mm×1500mm, 4000mm×2000mm, 6000mm×2000mm, 8000mm×2500mm can be selected Custom-made) sheet of breadth, with auxiliary pipe cutting function, can cut round pipe Ф25mm-Ф160mm, square pipe 25mm×25mm-100mm×100mm (diagonal 30mm-160mm), thickness 3-16mm, length 6-12m, cutting The seam is small, and the thermal effect is small, especially suitable for metal sheet (tube) processing .

Why Choose BS3015G

1. Powerful cutting function can meet customers' requirements for plane and pipe cutting at the same time.

2. Using pneumatic chuck push-cutting method, high centering accuracy and high processing accuracy.

3. After repeated CAE analysis and verification, the machine tool adopts integral profile welding structure. The finishing process after annealing eliminates the internal stress, better solves the stress generated by welding and processing, and improves the rigidity and stability of the equipment.

4. The gantry adopts high-strength aluminum alloy casting structure, which has the advantages of light weight and good dynamic response.

5. X/Y axis adopts precision helical gear transmission mechanism, which effectively guarantees the accuracy and speed of the cutting process.

6. The imported laser has good stability and long service life.

7. Excellent processing system, friendly interface, easy operation, processing status

Application field

★It can cut metal, various non-metallic sheets and pipes. It is especially suitable for cutting stainless steel, iron, aluminum, copper, titanium steel, ceramic wafers, silicon wafers, diamonds and other materials.

★Widely used in sheet metal, hardware, steel structure, precision machinery, auto parts, glasses, jewelry, nameplates, advertising, handicrafts, electronics, toys, packaging and other industries.

Optical fiber automatic focusing fiber cutting head NC30B

1. This cutting head has strong advantages in the application of medium-power large-format fiber laser cutting.

2. The internal structure of the laser head is completely sealed to prevent the optical part from being polluted by dust.

3. The laser head adopts two-point centering adjustment, and the focusing is driven by an imported motor, which is efficient in perforation

Significantly improved.

4. The protective lens is installed in a drawer type, which is easy to replace.

5. It can be equipped with various lasers with QBH connectors.

Laser Source

JPT single mode fiber laser(500W-2000W) is the optimal combination of optical, mechanical, electrical and software components. Through the controlling ports and the controlling software, the operating status of the laser can be monitored in real time, alarm messages can be received in time, and data can be collected. The laser uses water-cooling and shelf case design, with competitive advantage like high energy conversion (electric to light), low power consumption, maintenance free, fiber delivery, and easy to assemble, it is the most suitable laser source for industrial laser welding, cutting and other applications.

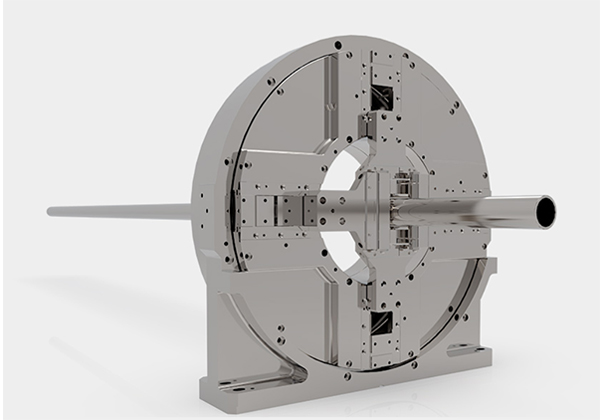

Automatic Chuck

1. The characteristics of the electric chuck are: fast speed, high precision and long life.

2. Through the switch on the electric control box, the clamping and unclamping of the power chuck driven by the motor can be realized, and the forward and reverse rotation of the motor can be controlled. Adjust the voltage adjustment knob on the electric control box to adjust the drive voltage. Changing the output torque of the motor and adjusting the clamping force of the chuck make it more convenient to use.

Yaskawa Reducer

It has the characteristics of economy and practicality, high cost performance, high precision, good rigidity, large carrying capacity, high efficiency, long life, light and small size, beautiful appearance, convenient installation, accurate positioning and so on. Suitable for AC servo motors, DC servo motors, stepping motors, hydraulic motors to increase and decrease the transmission speed. Suitable for connection of drive products manufactured by any manufacturer in the world

In the application of servo control, it exerts good servo rigidity effect, accurate positioning control, and has the characteristics of low and medium backlash, high efficiency, high input speed, high input torque, smooth operation, and low noise on the operating platform. Small appearance and structure design

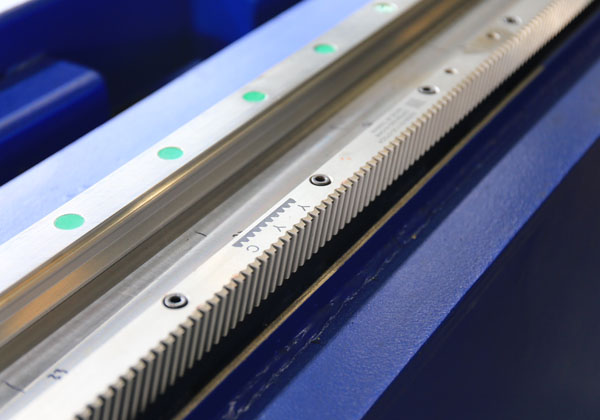

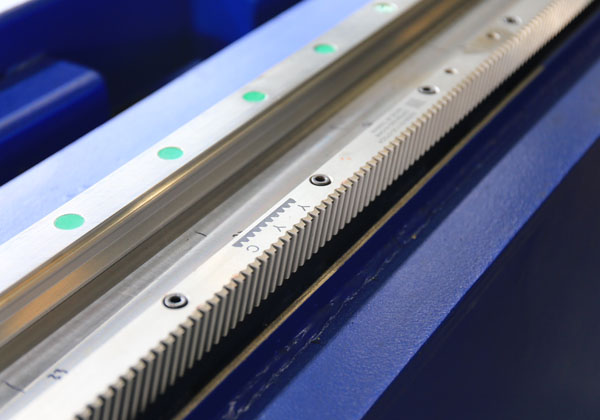

YYC Gear From Taiwan

To meet the needs of mechanical equipment, YYC provides racks and pinions with different modules, which can completely replace linear transmission products such as ball screws, cylinders, and linear motors, and have an excellent cost performance.

Tube Cutting Parts

1. High cutting precision, smooth and clean cutting, no burrs, and low material loss;

2. The heat-affected zone of laser cutting is very small, and there is almost no thermal deformation.

3. Mass production, high efficiency cutting. The standard pipe length is 6 meters. Traditional processing methods require very large fixtures. Laser processing can easily complete the positioning of several meters of pipe clamps, which makes batch processing possible.

The laser cutting machine is controlled by a digital system, which is one of the advantages of the laser cutting machine for cutting pipes. Laser cutting tube technology can handle any programmed shape and cut in any direction. It can realize a variety of cutting processes for complex tube structures, such as cutting, chamfering, grooving or perforating, scoring, etc.

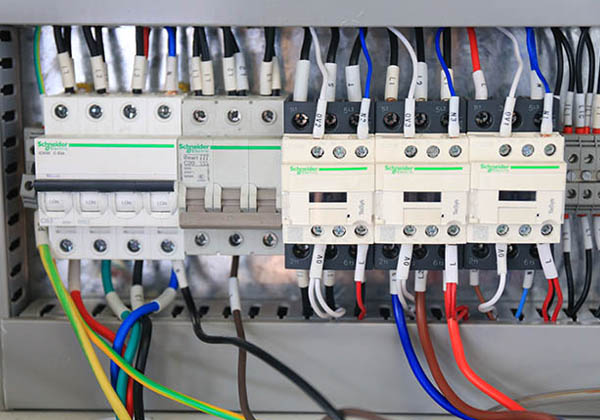

OTHER COMPONENTS

TECHNICAL DATA

| No. | Type | BS3015G | BS4020G | BS6020G | BS6025D | |||

|---|---|---|---|---|---|---|---|---|

| 1 | Machining area (Length *width) | 3000*1500mm | 4000*2000mm | 6000*2000mm | 6000*2500mm | |||

| 2 | X-axis stroke | 1525mm | 4020mm | 6020mm | 6050mm | |||

| 3 | Y-axis stroke | 3005mm | 2020mm | 2020mm | 2550mm | |||

| 4 | Z-axis stroke | 150mm | 150mm | 150mm | 240mm | |||

| 5 | Positioning precision of X/Y axis | ±0.02mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | |||

| 6 | Repetitive positioning precision of X/Y axis | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | |||

| 7 | Maximum speed | 140m/min | 100m/min | 120m/min | 140m/min | |||

| 8 | Maximum Acceleration speed | 1.5G | 1.5G | 1.5G | 1.5G | |||

| 9 | Tool weight | 5900KGS | 4500KGS | 5000KGS | 6500KGS | |||

| 10 | Maximum load of workbench | 1000KGS | 1500KGS | 2000KGS | 2000KGS | |||

| 11 | Laser Power | 1000W/1500W/2000W/3000W/4000W/6000W | ||||||

| 12 | Dimension ( Length * Width* Height) | 4500*2350*2000 | 6100mm*3500mm*1600mm | 8400*3600*2300 | 8400*4200*2600 | |||

| 13 | Number of Phases | 3 | 3 | 3 | 3 | |||

| 14 | Rated voltage of power source | 380V | 380V | 380V | 380V | |||

| 15 | Frequency | 50HZ | 50HZ | 50HZ | 50HZ | |||

| 16 | Protection rating of main power | IP54 | IP54 | IP54 | IP54 | |||

| 17 | Tube Diameter & Length | 220mm*6000mm length | ||||||