features

- Suitable for bending ultra-long plates.

- Combining three machines, it achieves a highly automated production process through advanced automation technology.

- Equipped with advanced CNC systems, which can achieve precise control of each bending station.

- Increased throat depth, stroke, and daylight for enhanced performance.

- Efficient tooling change and alignment for quicker operations.

- Simplify maintenance and repair processes for user convenience.

- Lower production costs for improved cost-effectiveness.

- Utilize components sourced from globally recognized and reliable brands.

Exporting country

0

+

Customer satisfaction Rate

0

/5

Professional team members

0

STANDARD Component

Other Components

Every part can ensure a long service life and reduce production costs.

Machine Frame

Durmapress press brakes feature a robust mono-block frame made from high yield steel, ensuring enduring accuracy and reliability. Each frame is tempered and backed by a 15-year warranty.

hydraulic System

Our firm delivers top-notch controllers sourced from esteemed brands like Delem, ESA, and Cybelec. These controllers are imported directly from reputable manufacturing hubs situated in the Netherlands, Italy, and Switzerland, respectively.

Backgauge

We use Taiwan PMI ball screw and linear guide for X-axis precision, ensuring higher accuracy than rod-based systems. The backgauge, controlled by a servo motor with a timing belt & wheel mechanism, offers precise positioning.

Motor

Servo motors are industry-standard for their energy efficiency, dynamic performance, and enhanced machine productivity. Compared to conventional motors, they can save up to 35% in energy, ensuring increased efficiency and lower operating costs.

Side Fast Clamp

Revolutionize your production efficiency with the ability to seamlessly interchange top punches. Streamlining your workflow, this feature ensures a swift and efficient process when adapting to diverse bending requirements.

front support

Press Brake Front Material Support is a device used to support and position metal workpieces during press brake operations. The front support material helps prevent the workpiece from sagging or bending, ensuring the accuracy and quality of bending.

R Axis Servo Motor

The R Axis Servo Motor is a crucial component in the operation of a press brake machine. Specifically dedicated to controlling the bending axis, the R Axis Servo Motor plays a pivotal role in achieving precision and accuracy during the bending process.

electrical carbinet

Harnessing the reliability of genuine Schneider components sourced directly from France, renowned for their unwavering stability, impressive durability, and prolonged lifespan.

Hydraulic System

Feature high-quality Rexroth hydraulic valves for durability and minimal maintenance. Our machines perform various actions, including rapid descent, slow descent, working-speed bending, rapid return, and emergency stop.

Ball Screw & Guide

The machine is equipped with precision ball screws and linear guide rails, providing a smooth and reliable operation that enhances overall performance. This advanced system ensures precise movements, reduces friction, and contributes to the machine's longevity, making it an ideal choice for demanding applications.

OPTIONAL Component

Other Components

Top-Quality Accessories from Leading International Brands

Crowning

To ensure accurate and consistent bend angles across the length of the workpiece, regardless of material thickness, reducing scrap and improving efficiency. It enhances the press brake's versatility by compensating for die deflection, ensuring that the final product meets desired specifications with precise bending angles. This adjustment of the bed's shape counters die deflection, ensuring accurate bends as per specifications.

Punches & Dies

The selection of press brake punches and dies is a crucial topic to be discussed prior to placing an order. Any desired bending shape is achieved through the use of an appropriate set of punches and dies. We offer a range of suitable tooling options to accommodate diverse bending requirements of our customers.

LaserCheck Bending Angle Measurement

Experience unparalleled precision with the iMeasure Laser angle measurement system in collaboration with Data-M Engineering, ensuring accurate bend angles with just one operation.

DSP Laser Protection

The DSP Laser Protection system monitors the intensity and location of laser radiation in real time to ensure that any possible laser safety hazards can be detected in time when the press brake is running.

CNC Controlled Sheet Followers

The latest followers for sheet metal bending aim to optimize the performances of our press brakes by reducing the time to set up the press brake and simplifying the work of operators. These bending aids provide operators with valuable practical assistance.

wila tool holders

We use WILA's innovative technologies, including Safety-Click®, Smart Tool Locator® and the E2M® replacement system for (heavy-duty) tools, to enhance the safety and convenience of replacement. Precision and ergonomics are carefully tailored for maximum productivity from all tools.

Structural Features of Hydraulic Cylinders

Our hydraulic cylinders are made of high-quality alloy steel for durability and reliability.

- Two-way Cartridge Valve: Diameter Dg16-Dg160, flow range 63 L/min-15000L/min.

- Liquid Filling Valve: Diameter Dg40-Dg400, flow range 300L/min-35000L/min.

- Traditional Plate Slide Valves: Include relief valve, sequence valve, one-way valve, solenoid directional valve, hydraulic control one-way valve, throttle valve, flow control valve.

- Cylinder Barrel: Made of high-quality alloy steel for strength and wear resistance.

- Piston: Forms a sealed cavity with the cylinder barrel, transmitting force through hydraulic pressure.

- Seals: Important for sealing and preventing leakage and contamination.

- Oil Port: Inlet and outlet for hydraulic oil entry, exit, and pressure adjustment.

Why Choose us?

1

innovative technologies

Utilizes innovative technologies in its machines, incorporating features that enhance performance, accuracy, and efficiency.

2

Optional System

DurmaPress machines come equipped with innovative features such as advanced control systems, automated processes, and safety features.

3

Muti Axis Control

DurmaPress offers a diverse range of metal fabrication machinery, catering to various needs in the industry.

durmapree factory

Watch the Video

Manufacturer of cutting-edge metal processing equipment

durmapree factory

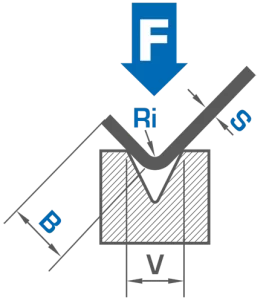

bending parameters calculator

How much force do you need to bend your piece

Bending Force Calculation

How much force do you need to bend your piece?

durmapree factory

Processing Equipment

Manufacturer of cutting-edge metal processing equipment

Contact us

Location

High Tech Industrial , Bowang Town, Maanshan, Anhui, China

Our Hours

7/24

Follow Us