Introduction

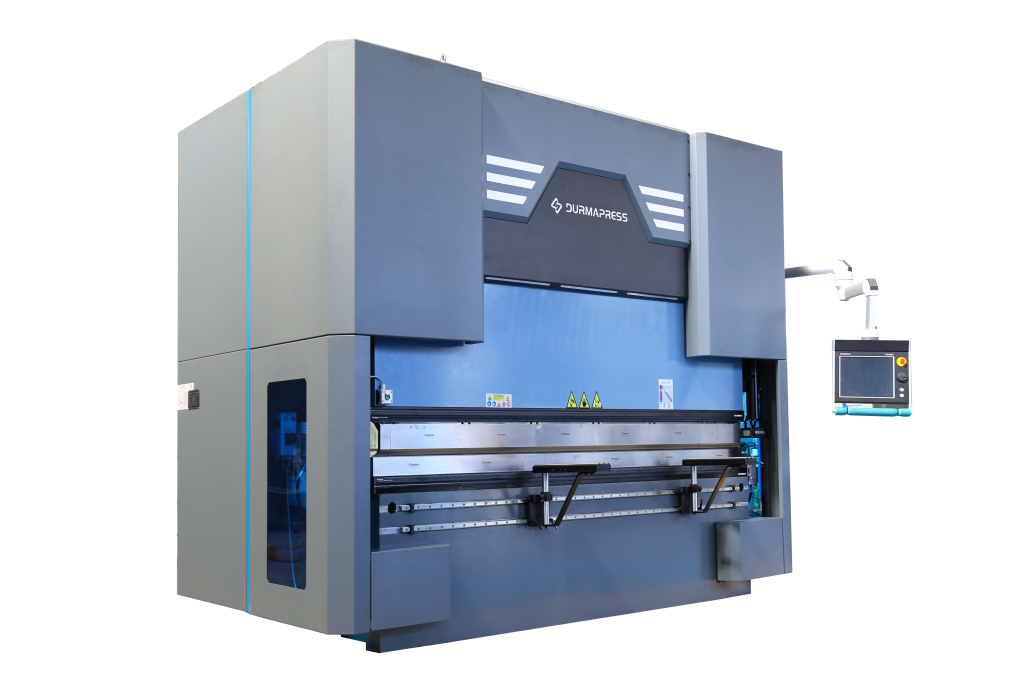

Press brakes play a vital role in the metal fabrication industry, mainly used for bending and molding metal sheets to specific angles and shapes. This machinery and equipment is widely used in producing various metal products in industries such as automobile manufacturing, aerospace, building structures, electrical equipment and furniture manufacturing. Through precise control of the bending angle and strength, the press brake can produce high-quality, high-precision metal components to meet the requirements of different industries on product performance and appearance.

In practice, press brakes often need to handle a variety of different thickness and length of the plate. Especially when it comes to bending long and heavy sheet materials, the operation process can face some challenges. Long sheet materials, due to their greater length, are prone to deformation and uneven bending during the bending process, which can affect the accuracy and quality of the final product. Heavy sheet materials, on the other hand, can pose safety hazards during handling and positioning due to their heavy weight, which also makes them more difficult to handle.

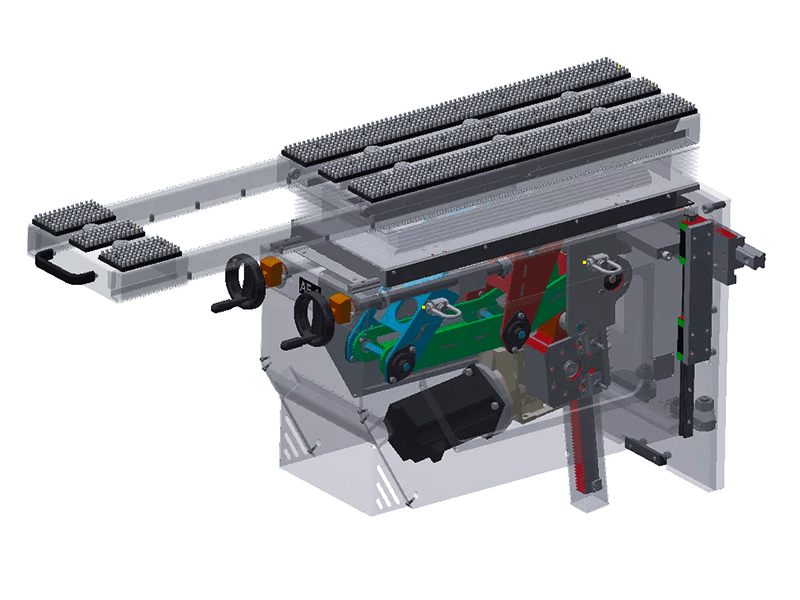

In response to these challenges, the Follower Palletizer was developed. A follower is an auxiliary device that automatically adjusts its position as the press brake progresses, providing additional support and stabilization. This device is usually installed between the slider and the table of the press brake, and can adjust the height of the pallet in real time during the bending process, to ensure the flatness and stability of the plate in the bending process. The use of the follower can make it easier for operators to handle long and heavy sheet materials, significantly improving productivity and product quality, while reducing labor intensity and safety risks.

Common Challenges in Bending Long Plates

During the bending process, the length and weight of the part can have a significant impact on the overall operation. Longer or heavier workpieces may deform during bending due to their own gravity, which can affect the final bending accuracy and quality. In addition, the length and weight of the workpiece can affect the balance of motion of the press brake, which may cause the machine to jitter or become unstable during movement, further interfering with the accuracy of the workpiece.

The interference of gravity and machine movement on workpiece accuracy is a problem that cannot be ignored. Gravity acting on longer workpieces may cause them to bend or deform during the bending process, and this interference is especially noticeable when the moving parts of the press brake are moving at high speeds. In addition, the precision and stability of the machine's movement directly affects the bending quality of the workpiece. If the machine jerks or deviates during the movement, the bent workpiece may have inaccurate dimensions, inaccurate angles and other problems, thus affecting the overall processing accuracy.

Traditional manually assisted pallets have obvious limitations and shortcomings in the bending process. Due to the length and weight of the workpiece, manual palletizing is not only labor-intensive, but also prone to operational errors, resulting in deformation or damage to the workpiece in the bending process. In addition, the efficiency of manual palletizing is low, which cannot meet the demand for high efficiency and high precision in modern production. Therefore, the traditional manual palletizing method in the bending process has been gradually replaced by automated equipment to improve production efficiency and processing accuracy.

Innovative design features of the randomized pallet device

The advantage of servo motor drive is that it can realize precise control and stability. This type of drive ensures the accuracy and stability of the equipment during operation by means of a high-precision feedback system and advanced control algorithms, thus improving processing quality and productivity.

The wider table and increased load capacity allow the machine to better cope with the demands of different workpieces. Both large and small workpieces can be machined in the right place on the widened table. At the same time, the increased load capacity ensures that the machine remains stable when handling heavy workpieces, avoiding damage or loss of machining accuracy due to excessive loads.

Coordination of linear and rotary movements of the pallets ensures accurate bending process. By precisely controlling the linear and rotary movements of the pallets, the machine is able to realize precise bending of the workpiece, ensuring the accuracy of the bending angle and position. This coordinated motion not only improves processing accuracy, but also reduces the risk of workpiece damage due to improper operation.

Technical advantages and applications of the device

Application examples: how to effectively utilize the trailing feeder to maximize its effectiveness in the actual production process.

In actual production, the introduction of the follower has played a significant role in improving bending accuracy, increasing production efficiency and reducing labor costs. Specifically, the trailing pallet device can automatically adjust the position of the material to ensure that the material is always kept in the optimal position during the bending process, thus significantly improving the bending accuracy. As a result, the quality of products produced is more stable, reducing rework and scrap caused by precision problems.

In addition, the automated nature of the palletizer greatly improves production efficiency. The traditional manual palletizing method is not only time-consuming and labor-intensive, but also prone to production interruptions due to improper operation. However, the trailing palletizer can work continuously, which reduces downtime and improves the overall efficiency of the production line. In this way, enterprises can produce more products in the same time to meet market demand.

Finally, the use of the follower palletizing device also significantly reduces labor costs. In traditional production, a large number of manpower to complete the pallet, handling and other work, which not only increases the enterprise's labor costs, but also easily due to human factors lead to production efficiency and product quality fluctuations. The automated operation of the follow-on palletizing device reduces the dependence on manual labor, thus reducing labor costs, and also improves the stability and predictability of the production process.

In summary, in the actual production, the introduction of the follower device not only improves the bending accuracy, improves production efficiency, but also effectively reduces the cost of labor, which brings significant economic benefits for the enterprise.

Practical application cases and benefits

In order to ensure the accuracy of the bending process, we have adopted the technology of precisely matching the bending trajectory and speed. This technology guarantees the bending accuracy and ensures that each bend meets the predefined requirements. Through this precise control, we can avoid bending errors caused by improper operation or speed mismatch, thus improving the overall production quality.

In addition, we have introduced a fully automatic CNC independent motion axis system, a system that greatly reduces the need for human intervention. Through intelligent control, the machine can complete complex bending tasks on its own, thus significantly increasing production efficiency. This automation technology not only saves labor costs, but also reduces production delays and scrap rates caused by human error.

To further enhance the working environment for workers, we are committed to reducing their labor intensity. By introducing advanced equipment and technology, workers are no longer required to perform heavy physical labor, thus enhancing work safety and comfort. This not only helps to improve workers' job satisfaction, but also reduces the risk of occupational diseases caused by prolonged and strenuous labor, thus safeguarding workers' physical and mental health.

Follow the maintenance and maintenance of the pallet device

Practical application cases and benefits

In order to ensure the long-term and stable operation of the palletizer, routine maintenance is essential. Below are some key maintenance points that will help you extend the life of the device:

- Regularly check the various parts of the device to ensure that there is no looseness or damage. Pay particular attention to key components such as drive chains, guide rails and bearings, as wear and tear on these parts will directly affect the performance of the unit.

- Clean the surfaces of the unit to remove dust and dirt. Use appropriate cleaners and tools, avoid using corrosive or strong alkaline cleaners that may damage the protective coating on the surface of the device.

- lubricate moving parts of the unit, such as bearings, gears, and chains, periodically. Select a suitable lubricant and lubricate according to the manufacturer's recommendations to ensure smooth operation of the unit.

- inspect the electrical system to ensure that all wiring and cables are intact and there is no risk of fraying or short-circuiting. Regularly check the tightness of electrical connections to ensure good contact.

- Monitor the operating condition of the unit, noting any unusual noises, vibrations or temperature changes. These may be early signs of potential problems, and timely detection and resolution of these problems can prevent larger failures.

There are some common problems that may be encountered during daily use. Here are some quick fixes to help you quickly return to normal operation:

- If the unit appears to be stuck or unable to move normally, first check if there is any foreign object stuck in the guide rail or chain. After removing the foreign object, restart the unit and observe if it returns to normal.

- If the unit makes an abnormal noise when running, it may be caused by insufficient lubrication or worn parts. Check the lubrication and add lubricant or replace worn parts if necessary.

- If the movement of the unit slows down or stops, check for malfunctions in the electrical system. Check the power connections and control panel to make sure all electrical components are working properly. If the problem persists, it may be necessary to contact a service professional for further inspection.

- If the unit appears to be inaccurately positioned, check that the sensors and encoders are working properly. Clean the surface of the sensor to make sure it is not obscured by dirt or dust. If the sensor or encoder is damaged, it needs to be replaced with a new part.

With the above maintenance points and quick fixes, you can effectively extend the service life of your follower palletizer and ensure its efficient operation during production. Regular maintenance and timely troubleshooting will help you avoid production interruptions and the risk of equipment damage.

conclusion

To summarize the significant improvement in bending operations with the pallet follower. Through its unique design and functionality, the Follower can effectively improve the accuracy and efficiency of bending operations. It automatically adjusts the pallet position to ensure material stability and consistency during the bending process, thereby significantly reducing processing errors and scrap rates. In addition, the follow-on pallet device can also reduce the labor intensity of the operator and improve production safety.

Emphasize the need to configure in the metal processing process and the future development trend of the follower device. With the modern manufacturing industry on processing accuracy and efficiency requirements are increasingly high, the application of the follower device in metal processing has become more and more extensive. It can not only improve processing quality, but also significantly improve production efficiency and reduce production costs. In the future, with the continuous progress of technology, follower device will move towards a more intelligent, automated direction, and further promote the technological innovation and industrial upgrading of the metal processing industry.

About Us

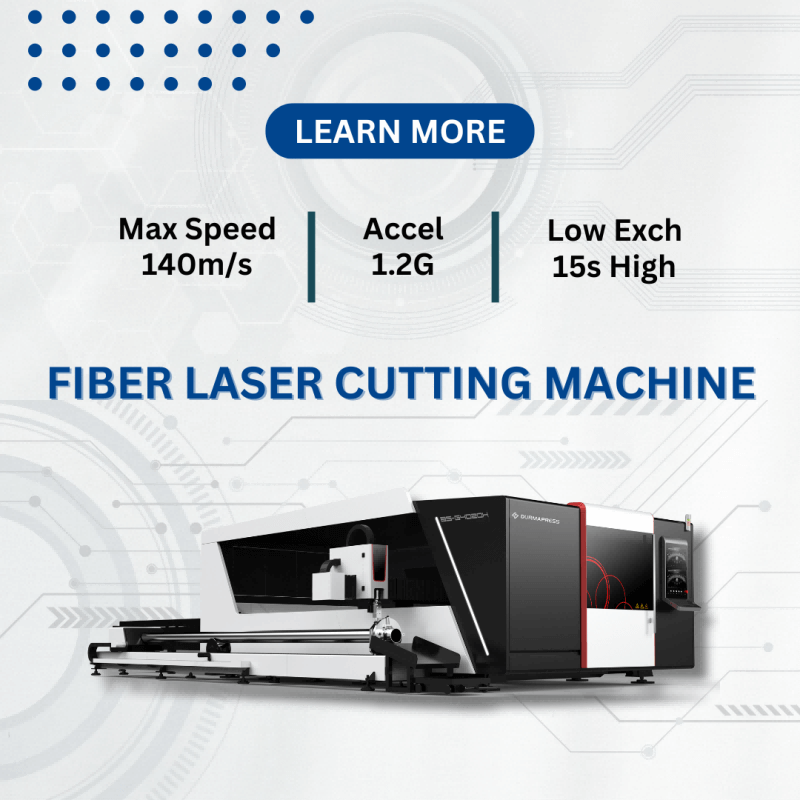

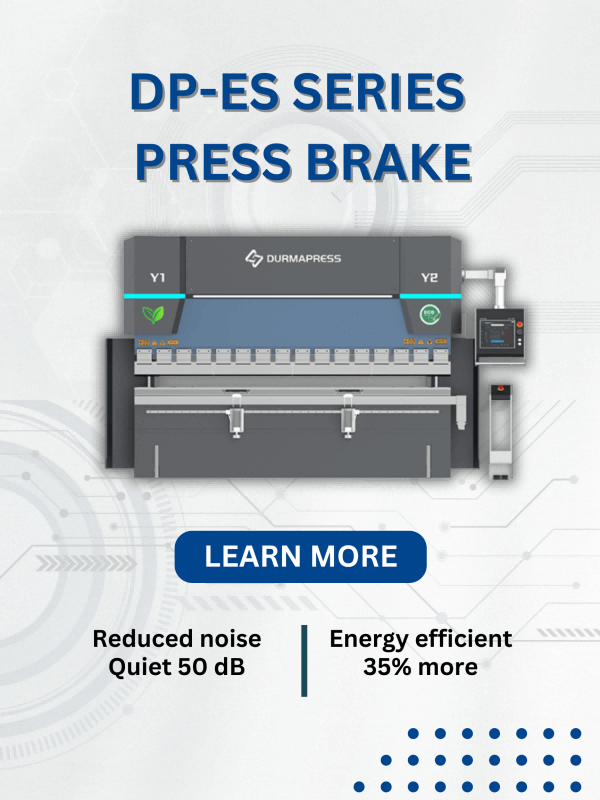

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.