-300x169.jpg)

The power conversion process of CNC press brake

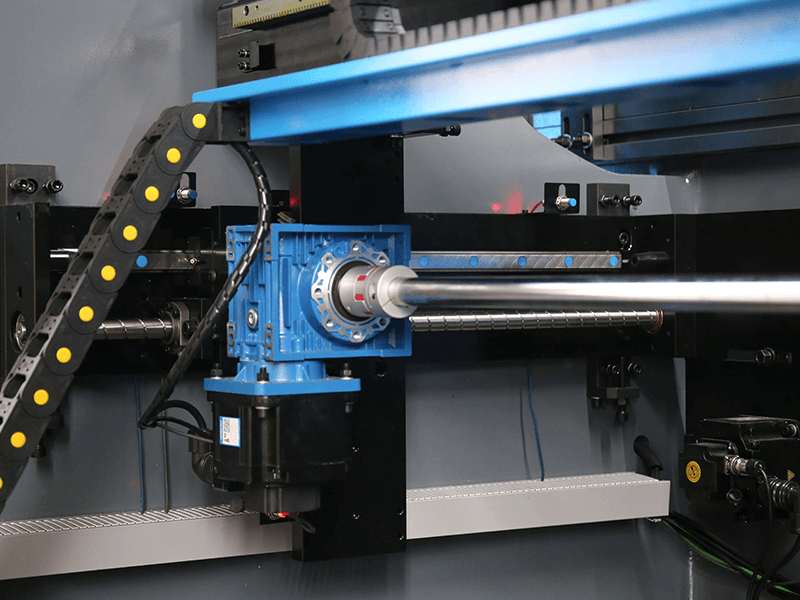

1.Electrical energy converted into mechanical energy

The electric energy conversion process of a CNC press brake mainly involves converting electric energy into mechanical energy to drive the press brake to work. This process includes the starting of the motor, the conversion of electric energy into mechanical energy, and the energy conversion during the bending process. In non-pure resistance circuits, in circuits containing motors, electrical energy can be converted into internal energy and mechanical energy. In circuits containing electrolytic cells, the electrical energy in the press brake is converted into internal energy and chemical energy. After voltage is applied to both ends of a DC motor, if the motor rotates, electrical energy is converted into mechanical energy. At this time, the circuit is not a pure resistance circuit, and Ohm's law is no longer applicable. If the motor does not rotate, no electrical energy is converted into mechanical energy. At this time, all the lost electrical energy is converted into internal energy. At this time, the circuit is a pure resistance circuit. When the CNC press brake is powered on, the motor starts to rotate and converts electrical energy into mechanical energy. In this process, the electrical energy generates a magnetic field through the motor coil, drives the rotor to rotate, and then drives the press brake slider and workbench to move. The press brake can convert electrical energy. Of course, this process is invisible to the user. During the whole process, electrical energy will be converted into mechanical energy. Through the conversion of energy, the plate can be effectively bent according to the pre-designed accuracy, which plays an important role in improving the efficiency of the equipment. Some calculations will be used in the process of electrical energy conversion, and the energy conversion situation can be known through calculations.

2.Working principle of CNC press brake

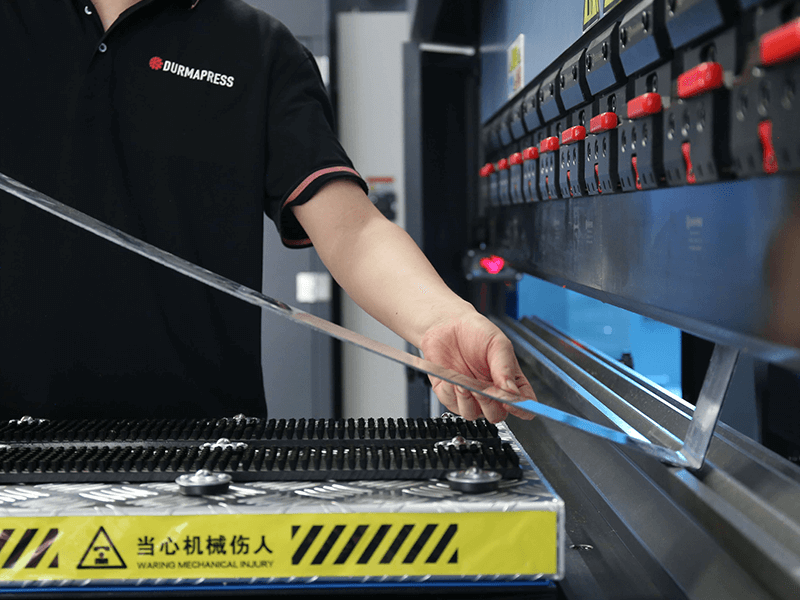

The working principle of a CNC press brake is to use the relative movement between the upper die and the lower die to apply pressure to the metal sheet, causing it to undergo plastic deformation under the action of the die and eventually form into the desired angle and shape. This CNC press brake mold is used to bend thin plates. The CNC press brake mold includes a bracket, a workbench, and a clamping plate. When in use, the coil is energized by a wire, and after energization, an attractive force is generated on the press plate, thereby clamping the thin plate between the press plate and the base. Due to the use of electromagnetic force clamping, the press plate can be made into a variety of workpiece requirements, and can process workpieces with side walls, and the operation is also very simple.

3.CNC press brake control system

The CNC system controls the bending process to ensure high precision of the bending operation. It receives the operator's instructions and accurately controls the operation of the motor, thereby driving the slider and the workbench to move according to the pre-set program. Therefore, the power conversion process of the CNC bending machine is the key to ensuring its efficient and precise operation. By understanding this process, we can better understand the working principle and control system of the CNC bending machine and use the equipment more effectively in practical applications.

4.The method of quick unloading by press brake

After the plate is bent to the ideal requirement, it can be unloaded from the press brake, which is the unloading process. However, this equipment often bends a variety of plates and often bends a large number of plates. Therefore, in order to improve efficiency and productivity, quick unloading is required.So how should we do it?First, the bending is performed according to the parameters specified by the press brake, requiring the thickness of the rolled plate to be 20mm, the maximum length to be 2500mm, and the yield of the rolled plate material to be less than 250Mpa. After the power is turned on, the lower roller moves in both the forward and reverse directions and the upper roller moves up and down, and check whether there is any abnormal jamming in each movement.Then strictly follow the press brake processing sequence and operation method to operate. When the upper roller is raised and lowered to the position, the upper roller can be raised and lowered, the tilting bearing can be reset, and the upper roller can be tilted after the main drive stops. During the operation, if any abnormal phenomenon such as irregular noise, impact, etc. is found, the machine should be stopped immediately for inspection.Finally, during the operation, all personnel must coordinate with each other and follow the instructions of the person in charge. When lifting steel plates or drums with a crane, be careful not to collide with the press brake.The press brake has high precision requirements and strict production operation requirements. All of the above operations can enable the equipment to unload quickly and improve production efficiency. After unloading, the equipment should be cleaned immediately to facilitate the next bending of the plate.

Advantages of CNC press brake

1.High-precision performance

CNC press brake has precise processing capabilities. The CNC system can control the position, movement speed and processing force of the upper die, thereby achieving high-precision bending and bending operations. Whether it is a complex shape or a fine angle requirement, the CNC press brake can accurately achieve it, ensuring the quality and accuracy of the product.The CNC press brake adopts advanced CNC technology, which can accurately control parameters such as bending angle and bending length to ensure high precision and consistency of processed products.Equipped with an automation system, the CNC press brake can automate the production process and significantly improve production efficiency. CNC press brake has precise processing capabilities. The CNC system can control the position, moving speed and processing force of the upper die, thereby achieving high-precision bending operations. Whether it is a complex shape or a fine angle requirement, the CNC press brake can accurately achieve it, ensuring the quality and precision of the product. CNC press brake adopts advanced CNC technology, which can accurately control parameters such as bending angle and bending length to ensure the high precision and consistency of processed products. CNC press brake is equipped with an automation system, which can realize the automation of the production process and significantly improve production efficiency. Compared with traditional press brakes, due to the characteristics of automation and intelligence of CNC press brake, a large number of processing tasks can be completed in a short time, greatly shortening the production cycle. At the same time, CNC press brake is easy to operate, reduces the labor intensity of manual laborers, improves work efficiency and the comfort of the working environment, and has a faster production speed, which can complete large-scale production tasks faster.

2.Flexibility and diversity

According to different processing requirements, CNC press brake can flexibly adjust processing parameters and processes to meet the processing requirements of different products. It can achieve precise bending of metal sheets of various complex shapes and has strong adaptability and diversity.CNC press brake has a high degree of automation and intelligence. Through advanced CNC system and programming software, operators can easily program and set processing parameters to achieve automated production. This not only greatly improves production efficiency, but also reduces human operation errors and errors, and improves product consistency and stability.

3.Cost savings

Automated operation reduces labor costs. At the same time, due to the high precision of CNC press brake and other advantages, its product quality is high, which can effectively avoid the problems of wasted time and cost due to uneven quality, and effectively reduce production costs.

4.High security

The use of international standard safety protection devices can effectively protect the safety of operators.These advantages make CNC press brake a very popular choice in modern manufacturing, especially in the field of metal processing that requires high precision and high efficiency.

DURMPRESS CNC press brake

Our company DURMAPRESS has DP-ES series of CNC press brakes, which can provide customers with different parameter requirements. The company can also recommend CNC press brakes with different parameters according to customer needs. Our DP-ES series of CNC press brakes have the following characteristics and advantages:Achieve precise bending with high accuracy. Durable frame with stress relief for added stability.Increased throat depth, stroke, and daylight for enhanced performance. Experience a stronger and faster machine with reduced operational noise through innovative design.Efficient tooling change and alignment for quicker operations.Lower production costs for improved cost-effectiveness.Utilize components sourced from globally recognized and reliable brands. Simplify maintenance and repair processes for user convenience.Durmapress always adheres to the concept of putting customers first in the whole purchase experience, and continuously optimizes and innovates the production process to cater to the needs of all large, medium and small manufacturing companies.The CNC press brake currently produced by DURMAPRESS can be designed and manufactured according to the needs of users, so that the work efficiency can be ensured during the use of the equipment, the equipment can better complete the clamping process, and the operation speed can be improved, reducing manpower and saving more costs for manufacturers. The functions of CNC bending equipment are more complete, and it can also achieve precise operation through automatic adjustment and other methods, and provide compensation for the equipment, so that the CNC bending equipment can better meet the needs of the industry during operation.

With the continuous advancement of science and technology, CNC technology will become more popular and mature. As one of the important applications of CNC technology in the field of metal processing, CNC press brake has great development potential and market demand.

As an intelligent choice in modern manufacturing, CNC press brake has many advantages such as high-precision performance, efficient production, flexibility and diversity. Choosing CNC press brake can not only improve production efficiency and reduce production costs, but also adapt to the continuous changes in market demand, injecting new impetus and vitality into the development of enterprises. In the future, CNC press brake will continue to play an important role and become one of the indispensable key equipment in modern manufacturing.

Summarize

In today's era of CNC, manufacturers are increasingly pursuing high-quality processing, and at the same time, they also pay more attention to improving efficiency. Therefore, CNC press brakes are becoming more and more popular in the sheet metal processing industry and have become the first choice of many manufacturers. The emergence of CNC press brakes has provided great convenience for production and processing, and also improved production efficiency. Compared with traditional press brakes, CNC press brakes use advanced electro-hydraulic servo systems, which make them have the characteristics of high efficiency and high precision in work, and the bending effect of materials is more accurate. In addition, CNC bending equipment can also complete operations such as repeated positioning, which meets higher-level operation requirements. This is why more and more manufacturers choose to install and use CNC bending equipment.

The CNC press brakes currently manufactured can be designed and manufactured according to user needs, so that work efficiency can be guaranteed during the use of the equipment, so that the equipment can better complete the clamping process, and at the same time, the operation speed can be improved, manpower can be reduced, and more costs can be saved for manufacturers. In addition, the functions of CNC bending equipment are more complete, and the purpose of precise operation can be achieved through automatic adjustment, and compensation can be provided for the equipment, so that CNC bending equipment can better meet the needs of the industry during operation.

In addition, CNC bending machine manufacturers can realize a variety of processing methods for press brake in actual production, which can not only ensure the utilization rate of machine tools, but also reduce energy consumption. At the same time, CNC bending equipment also adopts advanced CNC technology and is equipped with perfect electronic circuits and other devices to ensure the efficient operation of CNC bending equipment and provide more benefits for production and processing.

In short, CNC press brake plays an increasingly important role in the sheet metal processing industry. Its high efficiency, high precision and diversified functions can meet various different needs. With the continuous development of technology, it is believed that CNC press brake will continue to play its important role in the future and provide more efficient and intelligent solutions for production and processing.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)