Tendem Press Brake

General Features

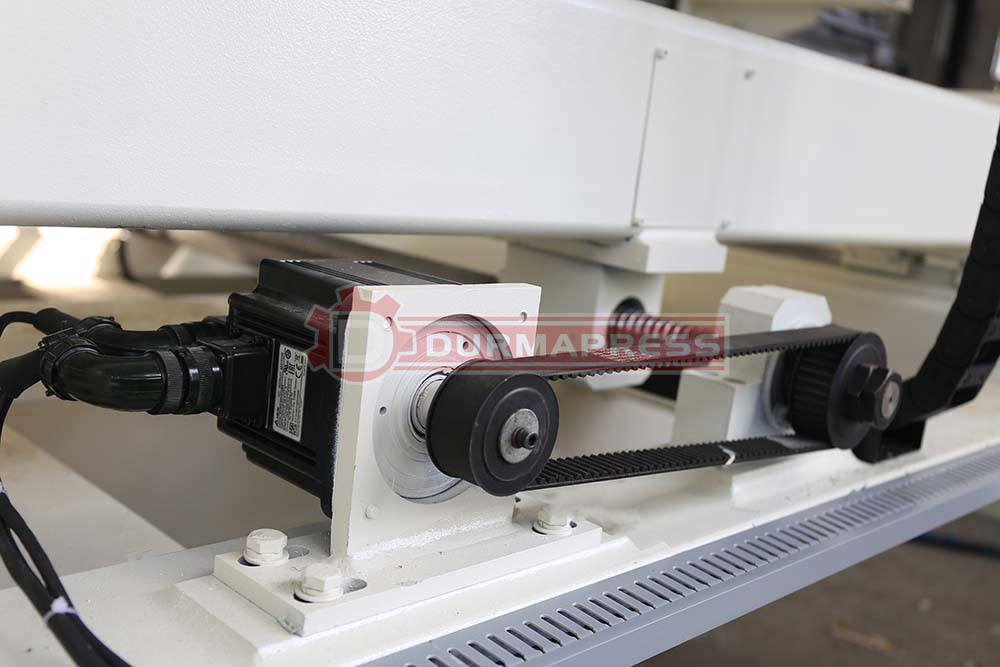

The whole equipment of full-thick steel plate is welded by electric welding, and the ground stress is removed by vibration after quenching, and the reliability is good; the equipment is shot blasted to remove rust and sprayed with anti-corrosion paint; the sound card frame is produced and processed by the imported CNC machine three-dimensional CNC machine tool. , To ensure the flatness and flatness of each mounting surface. The computer operating system can manipulate the Y1 and Y2 axes (Y1 manipulates the left hydraulic cylinder, Y2 manipulates the right hydraulic cylinder) to ensure that the guide rail slides are at the same time for fitness exercises, the X-axis controls the precision of the back gauge, and the R-axis controls the left and right specifications of the back gauge. Precision, the hydraulic machine operating console on the V-axis computer compensates for the precision. (Z1, Z2) The two fingers of the rear gauge move horizontally and independently for electric control

ESA S630 CNC Controller From Italy

Controller Data

- Numerical or optional 2D Graphical programming

- Equipped with 10” colour touch screen Backgauge control

- Angle programming

- Tooling libraries

- Simple manual" mode for quick bends

- Retract function

- Storage of thousands of part programs

- External USB memory stick port

- The most powerful in its class.

- 10” touch screen with powerful graphic.

- All the performances of a high-level cnc in an economical and user-friendly controller. High-level graphic programming for easiness of use and sophisticated algorithms to make the most of your machine.

- Direct management of any kind of servo valves with no need of external amplifiers.

- Can Manage up to four axes in any combination, including Electrical press brakes and Tandem.

Would you like the brochure ?

Angle station

Shearing station

Punching station

OTHER COMPONENTS