Press Brake

The press brake holds a crucial position in the realm of metal processing, serving as the pivotal equipment for achieving the bending and shaping of metal plates. Over the course of years, the technology behind press brake has undergone continuous advancements, transitioning from manual operations to the current state of CNC and intelligent automation, resulting in significant improvements in functionality and performance.

The press brake, as a specific type of press brake, is widely applied in various sheet metal bending processes, owing to its compact structure, user-friendly operation, and exceptional processing capabilities. Comprising components such as the body, table, bending axis, and control system, the stand-alone press brake achieves precise control over the bending axis through the control system, facilitating the bending of various angles and shapes!

Press brake play a pivotal role in the field of metal processing, serving as the core equipment to realize the bending molding of sheet metal. With the rapid development of science and technology, press brake technology has undergone decades of iterative updating, transitioning from the initial manual mode of operation to the modern level of numerical control and intelligence. This evolution has led to unprecedented advancements in the function and performance of press brake.

Among the many types of press brake, the single press brake has received widespread attention for its unique advantages. The stand-alone press brake, with its compact structure, easy operation, and excellent processing performance, has been widely used in the field of bending various types of sheet metal. The single press brake is mainly composed of the body, table, bending axis, and control system. Through the precise control of the bending axis by the control system, various angles and shapes of bending processing can be realized.

Tandem servo CNC press brake

Durmapress' Tandem Servo CNC Press Brake utilizes an advanced servo control system to achieve precise control of the bending process. The high-speed, high-precision servo drive ensures consistency and accuracy in every bend. Innovative design increases throat depth, stroke, and daylight to enhance performance while reducing operating noise, providing users with a stronger, faster operating experience.

The Tandem Servo CNC inline press brake is equipped with an efficient tool change and alignment system that speeds up operation and increases productivity. This technology also helps to reduce production costs and achieve greater cost-effectiveness. The use of components from globally recognized and reliable brands ensures the reliability and stability of the equipment.

At the same time, the design of this press brake focuses on simplifying the maintenance and repair process, making it easier for users to maintain and repair the equipment. These features make the Tandem Servo CNC press brake a state-of-the-art, efficient, reliable, and easy-to-maintain metal processing that meets the high demands for accuracy, speed, and reliability in the modern manufacturing environment.

Rack Side Quick Clamps

The rack-side quick clamp is a device for fixing workpieces, widely used in metal processing, tools, and other fields. It can quickly clamp and loosen the workpiece in a short period to improve production efficiency. The design and selection of quick clamps should consider factors such as clamp rigidity, clamping force, ease of operation, etc., to meet the needs of different machining processes.

Backstop

The backstop is a device used to control the cutting position of metal, commonly used in punching machines, cutting machines, and other equipment. The backstop device can precisely control the feeding speed and cutting length of the sheet to ensure the stability and consistency of the product size. In the process of sheet metal processing, the role of the backstop is crucial, directly affecting the quality and precision of the product.

CNC Sheet Follower

The CNC sheet follower is an equipment component controlled by CNC technology, capable of realizing the automatic processing of the sheet. CNC sheet followers have characteristics such as high precision, high efficiency, and high stability. They are widely used in the cutting, engraving, bending, and other processing of various metal sheets. By combining with computer programming, CNC sheet followers can realize mass production of complex parts to meet various engineering needs.

Engine Electrical Parts

As the core component of automobiles, machine tools, and other equipment, the electrical parts of the engine are vital to the operation of the whole equipment. Engine electrical parts mainly include the ignition system, fuel injection system, sensors, generator, starter motor, etc. These parts ensure that the engine can work efficiently and stably by cooperating with each other. During engine repair and maintenance, it is important to check and replace damaged electrical parts to ensure the normal operation of the engine.

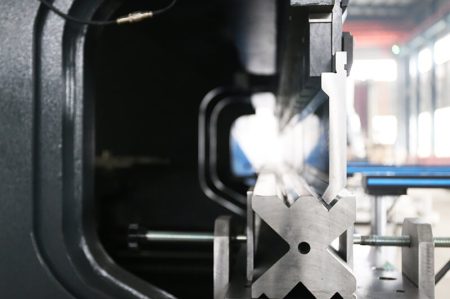

Punch and Mold

Punch and die are crucial components in stamping equipment, primarily used to achieve the deformation and forming of metal plates. The design and manufacturing level of punches and dies directly impact the quality and productivity of stamped products. During the stamping process, factors such as material, hardness, durability, and others related to punches and dies must be strictly controlled to meet the processing needs of different products.

DSP Laser Protection

DSP (Digital Signal Processing) laser protection is a laser safety measure realized through digital technology. During laser processing, DSP laser protection monitors the position and intensity of the laser beam in real time to ensure the safety and stability of laser processing. Through real-time adjustment of laser parameters, DSP laser protection can effectively avoid failures and accidents during laser processing, improving the service life of laser equipment.

Laser Check Bending Angle Measurement

Laser Check is a state-of-the-art bending angle measurement system for the bending of various metal sheets. Utilizing laser technology, Laser Check accurately measures the bending angle of a sheet to ensure that the product meets the design requirements. The use of Laser Check in metal processing contributes to improving product quality and machining accuracy across a wide range of engineering needs.

In summary, these technical components play a vital role in modern manufacturing, enhancing productivity and product quality. Understanding and mastering the principles and applications of these technical components are crucial for enhancing the competitiveness of China's manufacturing industry.

Emphasizing Cases for Tandem Servo CNC (Precision and Efficiency)

Tandem Servo CNC press brake demonstrates superiority in precision and efficiency in specific production scenarios. The synchronized operation of Tandem press brakes can significantly enhance productivity and accuracy, especially in scenarios where complex or large-scale parts require precise and efficient bending. The coordinated efforts of Tandem press brakes can reduce processing time, improve bending precision, and contribute to overall manufacturing efficiency.

Specific Production Scenarios and Requirements Suitable for Tandem Press Brake

Large-scale production of complex parts: Tandem Servo CNC press brake is well-suited for scenarios involving the mass production of intricate components, where synchronized operation enhances efficiency.

High precision requirements: Applications demanding high precision in bending angles and shapes benefit from the coordinated efforts of Tandem press brakes, ensuring accuracy in the final products.

Complex shapes and angles

Tandem press brake is advantageous when dealing with parts that require bending at multiple angles or intricate shapes, providing flexibility and precision in the manufacturing process.

tridem press brake

The tridem press brake stands out as an efficient and flexible bending equipment highly favored by enterprises in the modern metal processing industry. This discussion will delve into the structure and production mode of the tridem press brake, comparing its performance and flexibility with single press brake and Tandem Servo CNC press brake press brakes. Additionally, examples will illustrate its application in large-scale production, along with insights into the equipment, work interactions, and content involved in quadrem Press Brake . Industry applications and case studies from durmapress will be shared to highlight the benefits and results of different press brakes in actual industries.

Structure and Production Method of tridem press brake

A tridem press brake comprises a loading mechanism, a bending mechanism, a lowering mechanism, and a control system. Through the cooperative operation of these tridem press brake, high-speed, high-precision bending processing is achieved. The production modes include continuous bending (suitable for large quantities of single-shaped parts processing), step bending (suitable for diversified small-batch parts processing), and multi-station bending (allowing for various shapes and angles in complex parts processing).

Comparison of tridem press brake with Single press brake, tandem press brake in Performance and Flexibility

Performance: The tridem press brake, compared to a single press brake and tandem press brake , exhibits higher productivity. In the tridem press brake mode, loading, bending, and material processing occur simultaneously, significantly reducing the processing cycle.

Flexibility: The tridem press brake demonstrates superior adaptability. It can achieve automatic switching between various stations, catering to different processing needs for parts of varying shapes and sizes. In contrast, the flexibility of the single press brake and tandem press brake is relatively lower.

Tridem press brake in Large-Scale Production

Illustrating with an example from an automotive parts manufacturer, the enterprise employs a tridem linked press brake for processing body parts. The efficient and flexible processing of the tridem linked press brake enables mass production to meet market demand. Coordinated operation with automatic loading and unloading equipment, robotic welding equipment, and other automated systems further enhances production efficiency and reduces costs.

quadrem press brake

The quadrem press brake stands out as a high-efficiency, high-precision metal processing equipment comprising four independent bending units, each equipped with an independent drive motor and control system. In practical applications, these four units work collaboratively to achieve one-time bending of complex parts. The following provides a detailed introduction to the equipment involved in the quadrem Press Brake press brake, the way and content of work interaction, and examples illustrating its use.

Equipment and Work Interaction Modes in quadrem Press Brake

The quadrem Press Brake press brake involves quadrem press brakes working together through a control system. These machines can operate synchronously, asynchronously, and in other modes. The synergistic interaction between the machines enables the quadruple press brake to achieve more efficient and higher precision bending processing.

Participating Equipment

Feeding Equipment: Responsible for feeding the sheet metal to be processed into the working area of the press brake.

CNC System: Controls the operation of the quadrem Press Brake press brake, facilitating the setting and adjustment of bending angle, speed, and other parameters.

Molds: Used to achieve metal plate bending molding. Depending on the different parts to be processed, corresponding molds need replacement.

Detection Equipment: Monitors bending process parameters such as bending angle, strength, etc., to ensure processing quality.

Way and Content of Work Interaction

The feeding equipment feeds the sheet metal into the press brake working area.

The numerical control system regulates the four bending units based on preset bending parameters.

The molds bend according to the shape and size of the parts to be processed.

Inspection equipment monitors bending process parameters in real-time. If any abnormalities are detected, the CNC system adjusts parameters promptly to ensure processing quality.

During the bending process, manual intervention can be used if necessary to adjust feeding speed, bending angle, and other parameters.

High Precision and High Efficiency

Adopt more advanced control systems to enhance the speed and accuracy of the press brake.

Optimize the design of bending molds and tools to improve mold life and bending quality.

Introduce intelligent sensors for real-time monitoring and automatic adjustment, ensuring bending accuracy.

Green Environmental Protection and Energy Saving

Adopt energy-saving motors and drive systems to reduce energy consumption.

Optimize the bending process to minimize waste generation and resource waste.

Use environmentally friendly materials to reduce the environmental impact throughout the product's life cycle

Intelligent and Automation

Introduce machine learning and artificial intelligence technology for the adaptive adjustment of the press brake.

Develop a remote monitoring system for real-time understanding of the press brake's operating status, providing remote fault diagnosis and maintenance.

Interconnect with other intelligent manufacturing equipment to realize the automated operation of the production line.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.

-300x169.jpg)