Durmapress Will Be Participating in FABEX 2024 as a Highly Anticipated Metal Processing Product Merchant

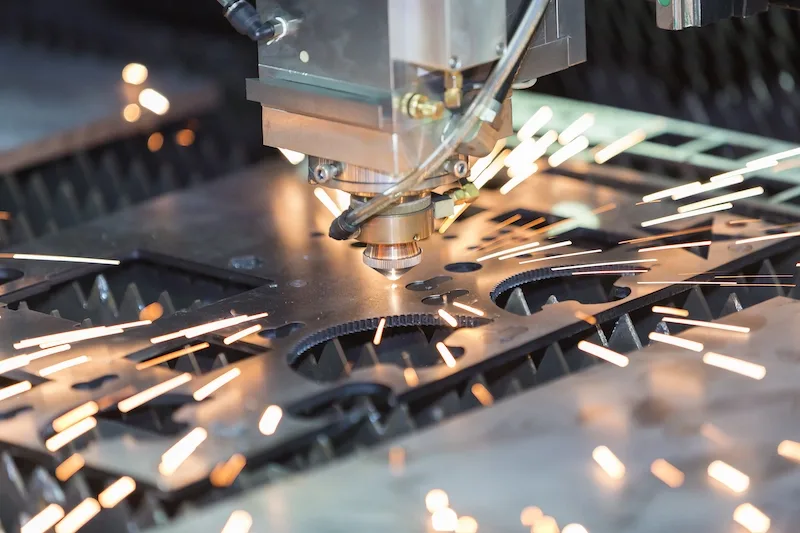

As a large metal processing manufacturer in China, it is delighted for Durmapress to participate in this grand exhibition. Our products include but are not limited to DP-ES series press brake, shearing machine, rolling machine, fiber laser cutting machine. Each product has been well received and loved by customers all over the world, and each product is a confident work of Durmapress.