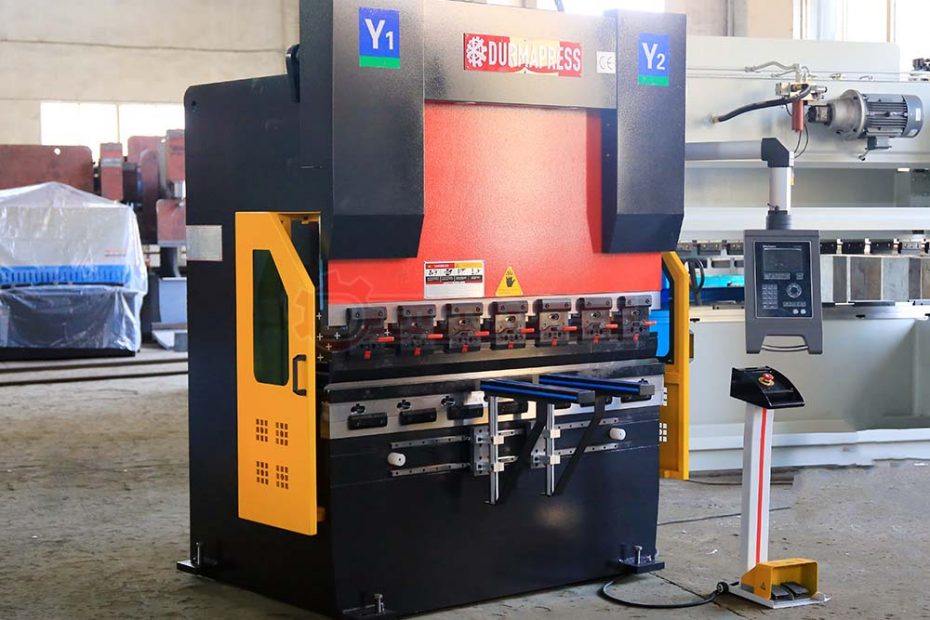

Hydraulic Press Brake Machine factory tutor you how to maintain

Hydraulic Press Brake Machine factory tutor you how to maintain Precautions for use of bending machine 1. Before running the bending machine, the tools used must be matched with the control program 2. Be sure to close the bending machine after the end of the work Two ways to close the bending machine 1. Close the machine to the middle of the bottom dead center, that is, move the slider to the center of the bottom dead center, close the… Read More »Hydraulic Press Brake Machine factory tutor you how to maintain