What factors are related to the bending degree of Profile iron bending machine

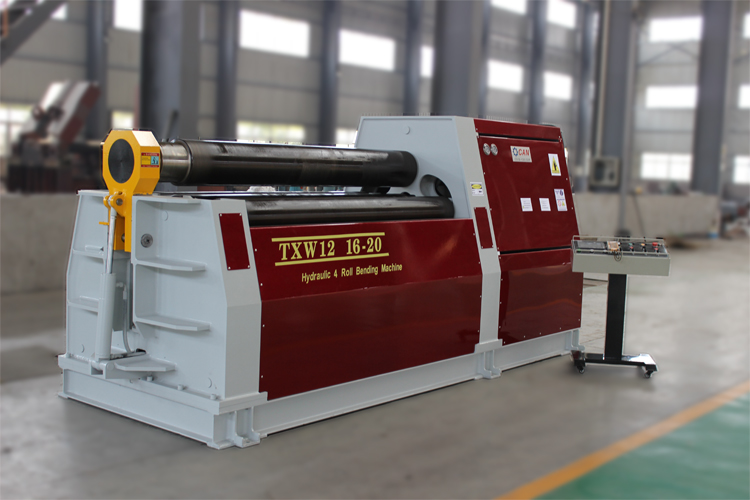

Profile iron bending machine is three-roller bending machine under arc, bed for steel plate structure, do eliminate internal stress processing, the main roller transmission through the hydraulic system through the hydraulic motor, gear, sprocket transmission to power to do rotary motion two side roller, This is done in an arc around the collar: the power transmitted through the hydraulic motor and gears to the main roller through the hydraulic system is transmitted to the primary roller for rotary motion; the… Read More »What factors are related to the bending degree of Profile iron bending machine