Maintenance of hydraulic sheet bending machine

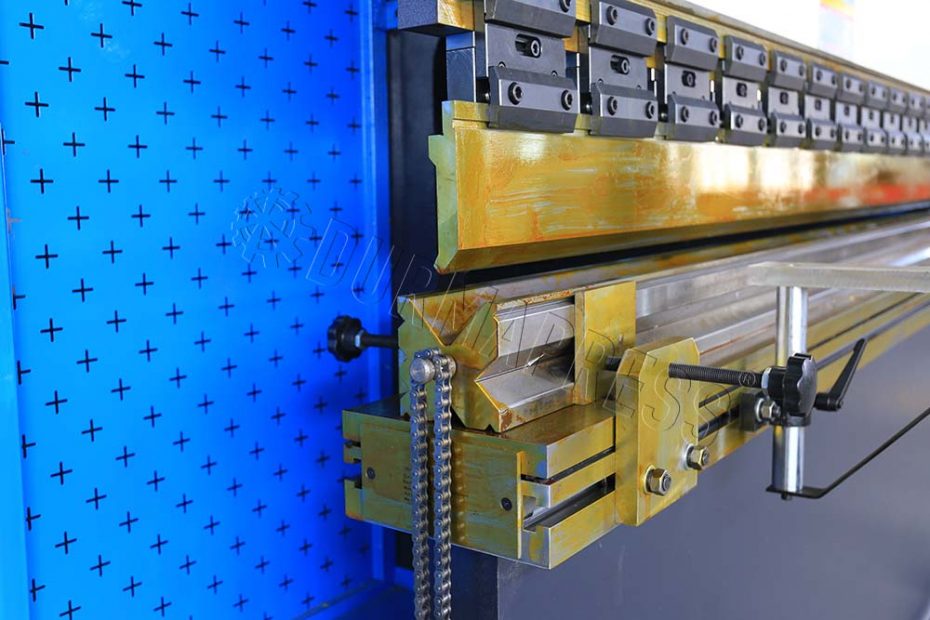

1, strictly abide by the machine tool operation rules, wear labor protection equipment according to the provisions; 2, before the boot should be on the mold, under the production model tidy up, cleaning, the slot shall not be iron Hazi what foreign body, otherwise destroy the production model, affect the correctness of the work hydraulic sheet bending machine. Before starting carefully check whether the motor, switch, line and grounding is normal and firm, check the operating parts of hydraulic sheet… Read More »Maintenance of hydraulic sheet bending machine