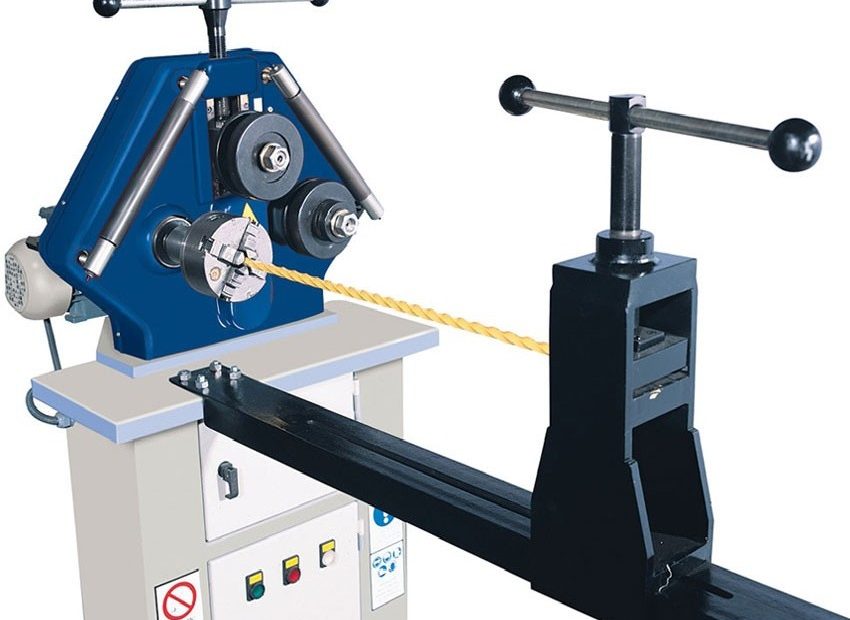

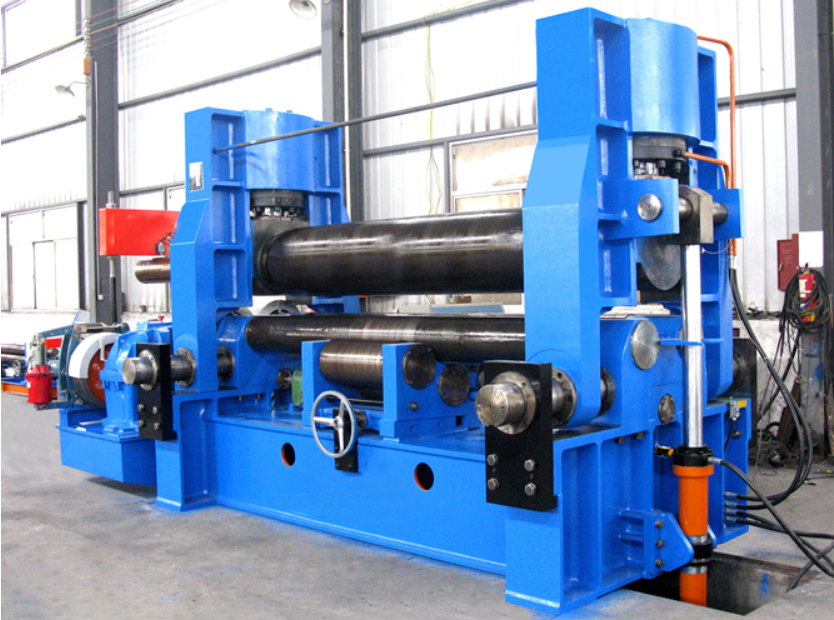

Application and working principle of four-roll profile bending machine

Working principle of four-roller profile bending machine: Volume of arc mode under profile bending machine, the machine of two side roll roll, can also be three or four work roll roll, the roll fixed position, two side roll around because of the rotary center for arc lifting move, hydraulic control, the displacement of the liquid crystal display, is helpful to control profile forming process, high on both sides of the roller device, to ensure the rolling quality of asymmetrical section.… Read More »Application and working principle of four-roll profile bending machine