The bearing of three-roller plate winder improves service life

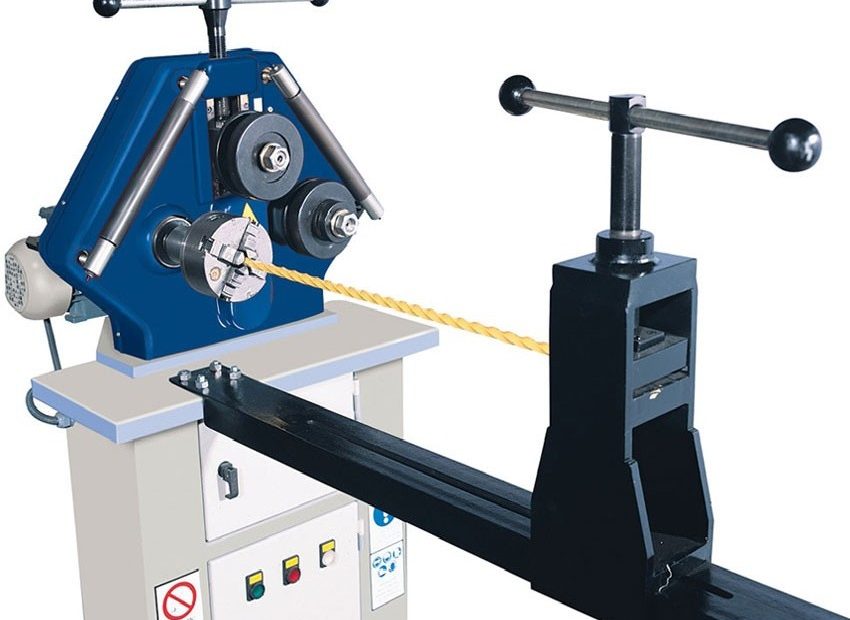

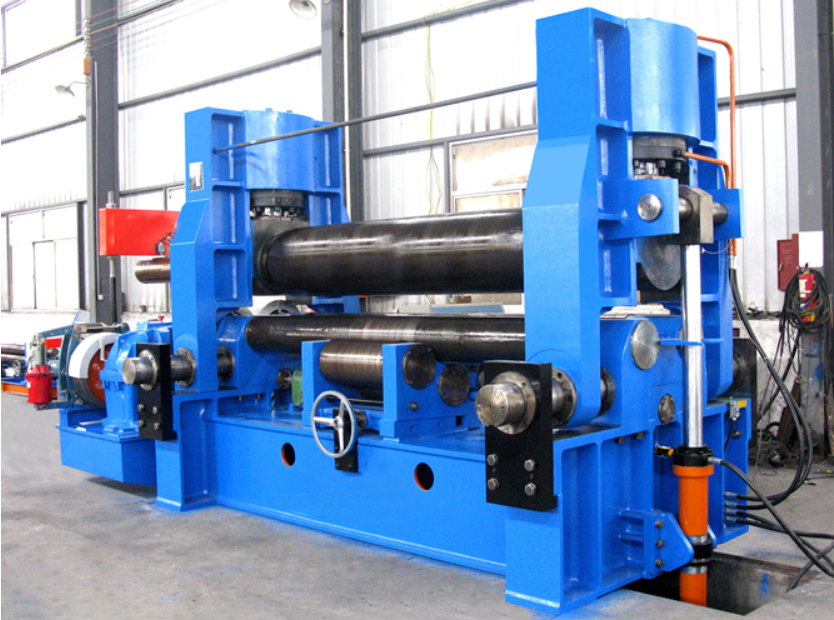

Three-roll plate machine has mechanical and hydraulic: mechanical three-roll plate machine is divided into symmetric and asymmetric. The sheet metal can be rolled into a circle, arc and cone within a certain range The workpiece. Rolling bearing is a precision part of the three-roller bending machine, so it is required to be cautious when using it. The correct use can not only achieve the desired performance effect, but also It can prolong the running time of the bearing of the… Read More »The bearing of three-roller plate winder improves service life