Popularize the use and classification knowledge of hydraulic Press Brake Machine

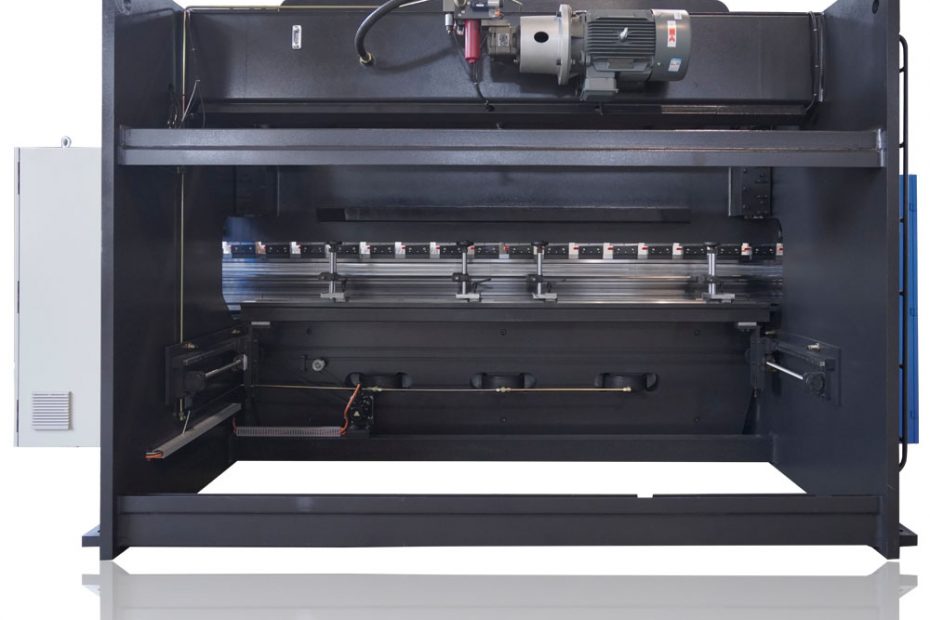

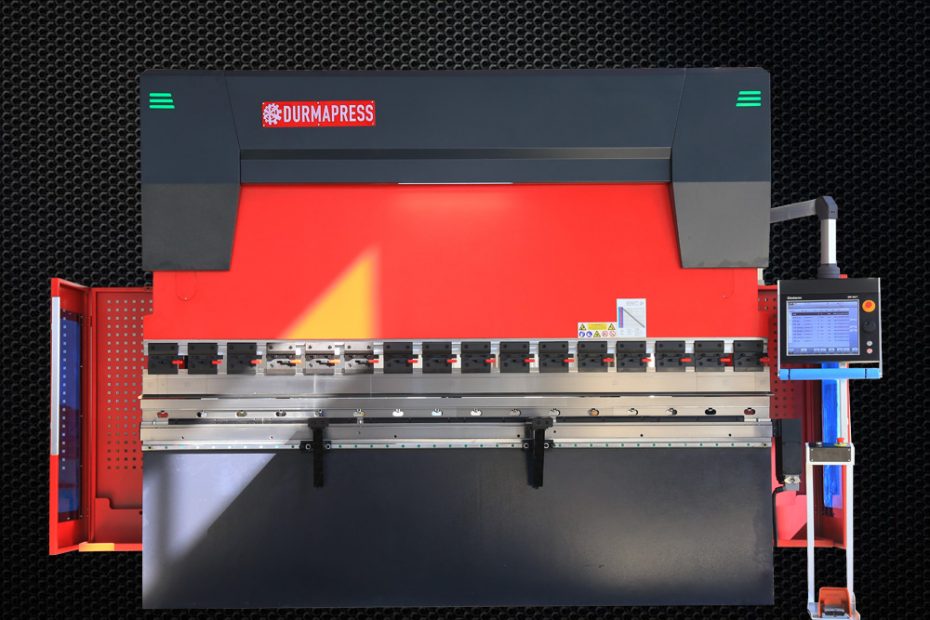

When it comes to hydraulic Press Brake Machine, many friends may feel very confused. What is this equipment? Indeed, most of us don't know what a bending machine is, but we can tell by its name that it is a machine, but what exactly is a machine for? That's unknown. So, let's get to know what the bending machine is. A, use Bending machine is a kind of thin plate bending equipment, similar to stainless steel sheet, iron sheet, copper… Read More »Popularize the use and classification knowledge of hydraulic Press Brake Machine