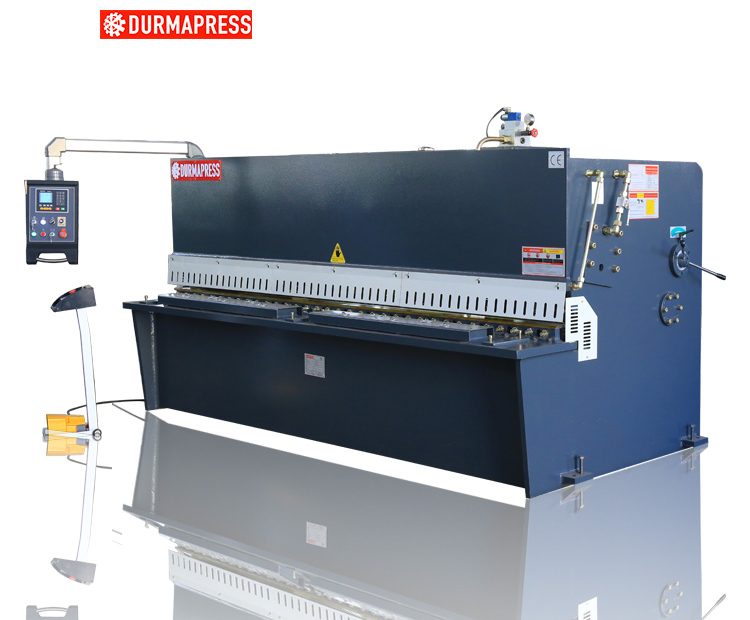

Notes for the operation of two-roll plate rolling machine

Notes for the operation of two-roll plate rolling machine Two-roll plate bending machine is a common mechanical equipment, in the case of improper operation, it is easy to happen accidents, resulting in tragedy.In the process of operating the two-roll rolling machine, Wuxi two-roll rolling machine, we must pay attention to the following points, in order to work in the two-roll rolling machine staff safety. 1, workers in the use of rolling machine before must pass special training, skilled operation can… Read More »Notes for the operation of two-roll plate rolling machine