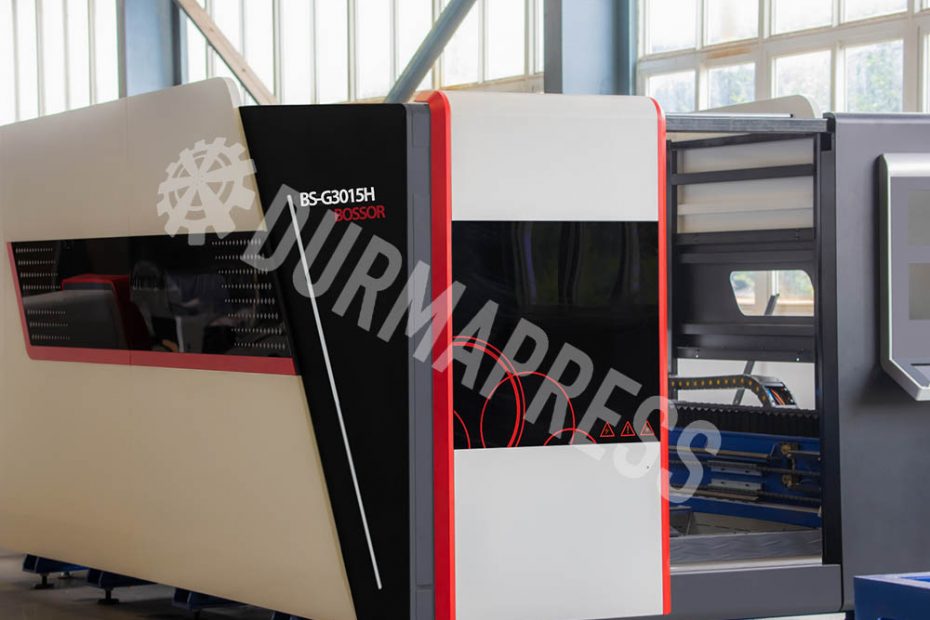

BS-T Series Tube Fiber letter cutter features

BS-T Series Tube Fiber letter cutter features: (I) Performance characteristics of BS-T Series Tube Fiber letter cutter: 1. Dual servo motor drive. 2, with higher stability, higher speed and faster acceleration. 3. Fully digital CNC servo motor communication. 4, New peripheral design, from three different directions to enter the equipment working area. 5, The machine adopts gantry structure, imported reducer and high precision linear guide rail, smooth transmission, high precision, greatly improve the production efficiency of the machine tool. 6,… Read More »BS-T Series Tube Fiber letter cutter features