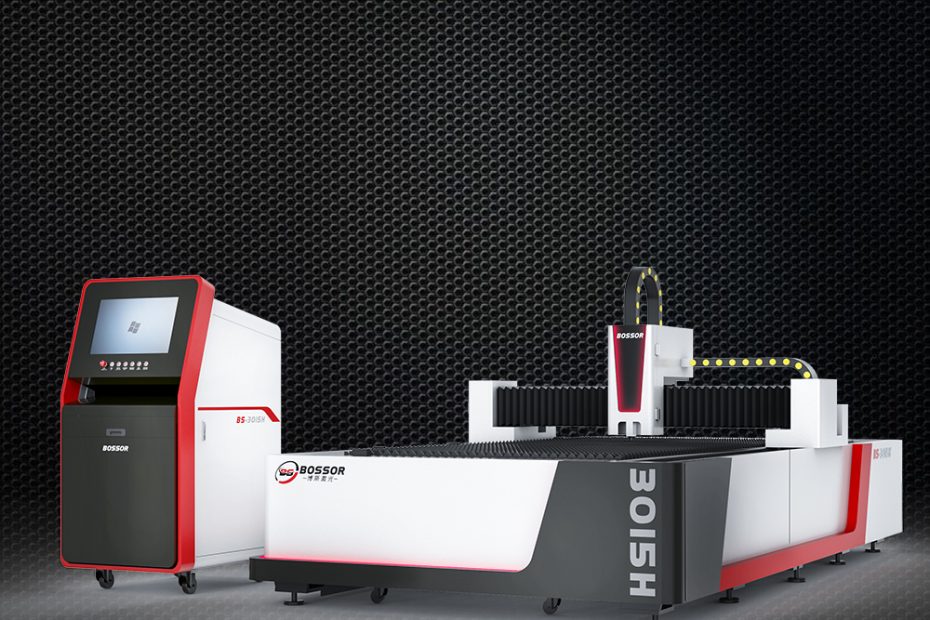

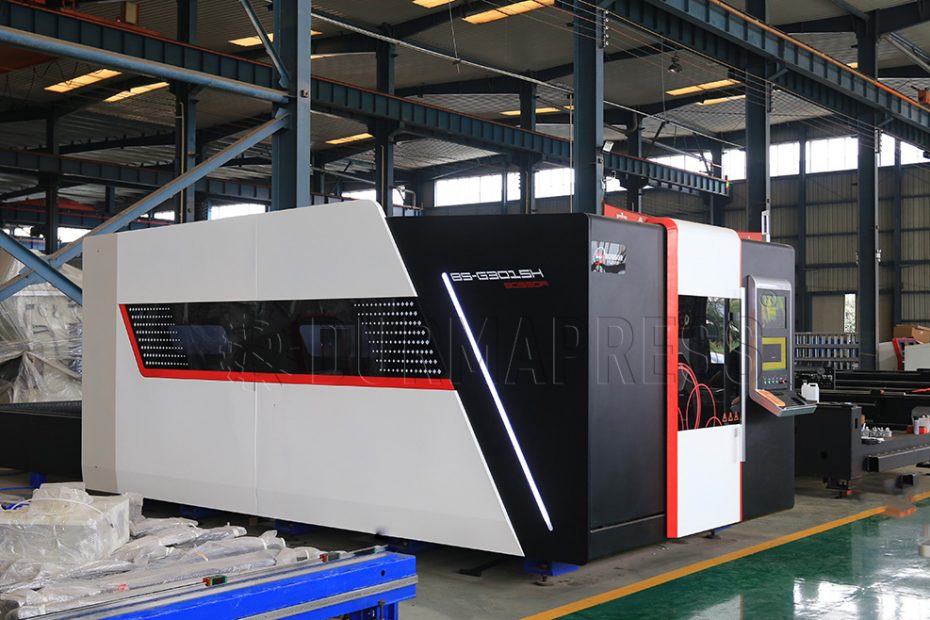

Extremely high cutting speed: twice that of the same power CO2 laser cutting machine

Metal laser cutting machine adopts gantry structure machine tool, aluminum beam, imported grinding helical rack and pinion, imported high-precision linear guide drive system, CNC system adopts German professional cutting CNC system, is a set of laser technology, mechanical technology, CNC technology and other advanced technology in one of the high-tech products. · Excellent beam quality: smaller focusing spot, finer cutting lines, higher work efficiency and better processing quality. · Extremely high cutting speed: twice that of the same power CO2… Read More »Extremely high cutting speed: twice that of the same power CO2 laser cutting machine