What Is Involved In Robotic Automation Planning?

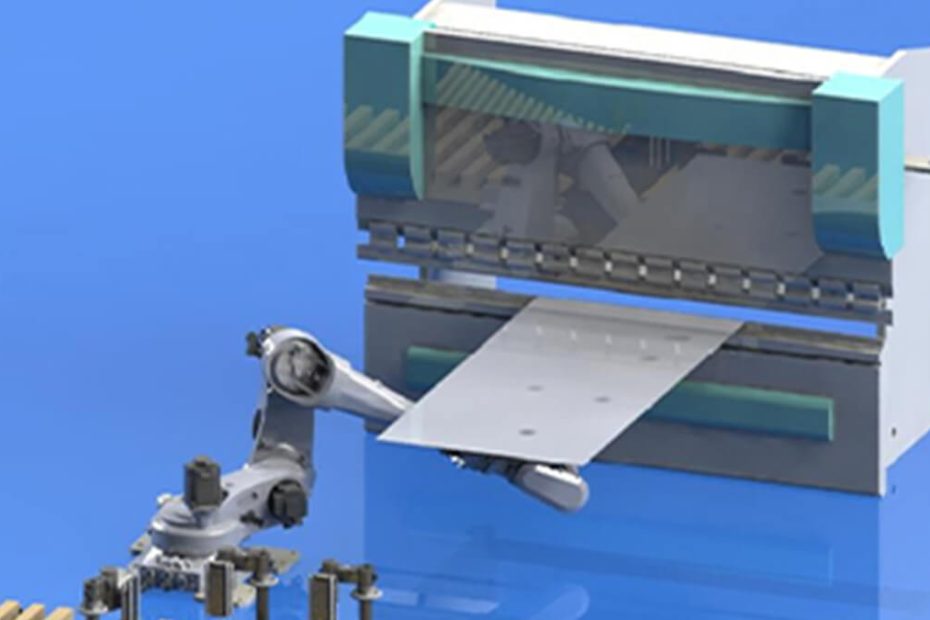

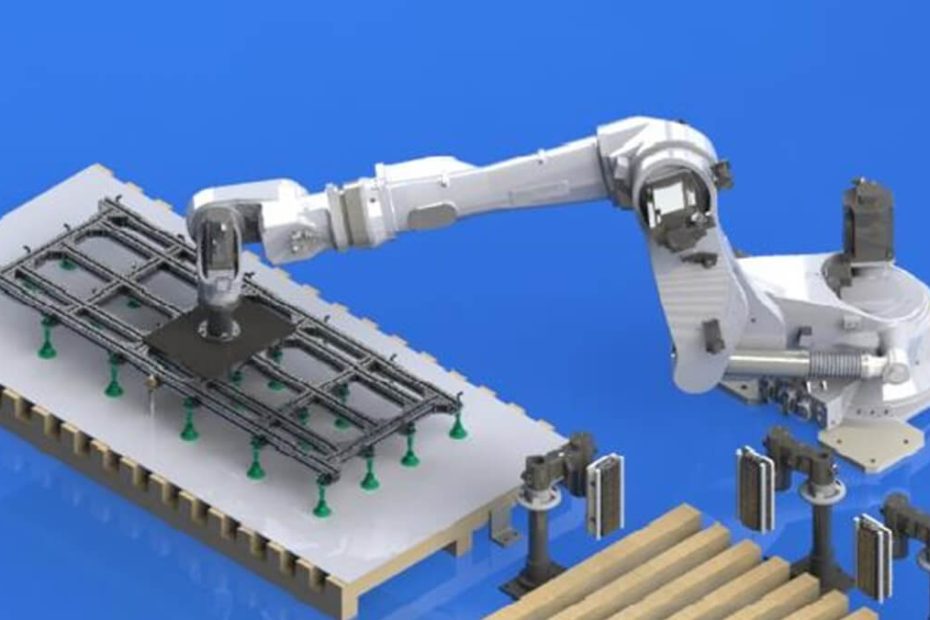

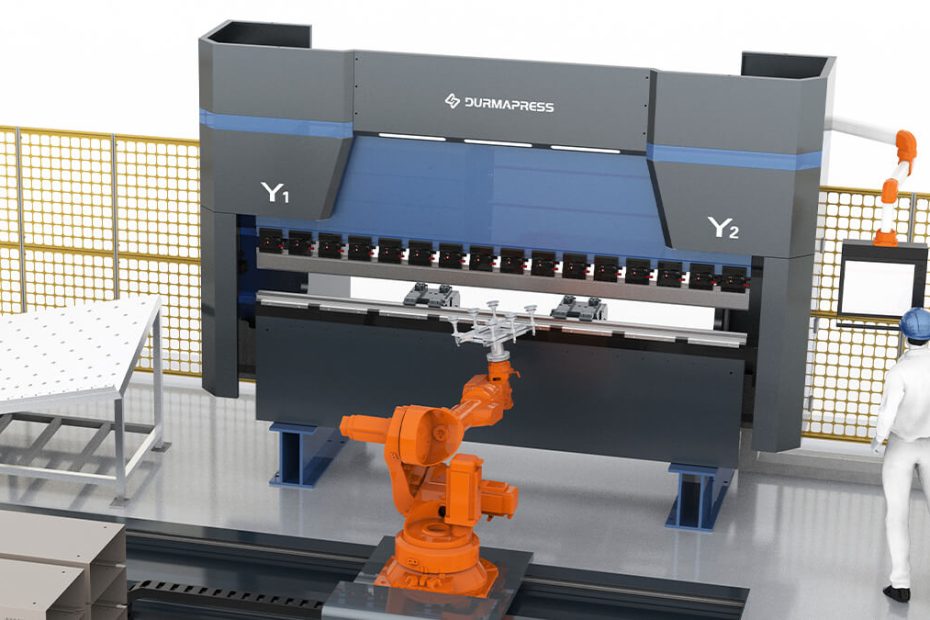

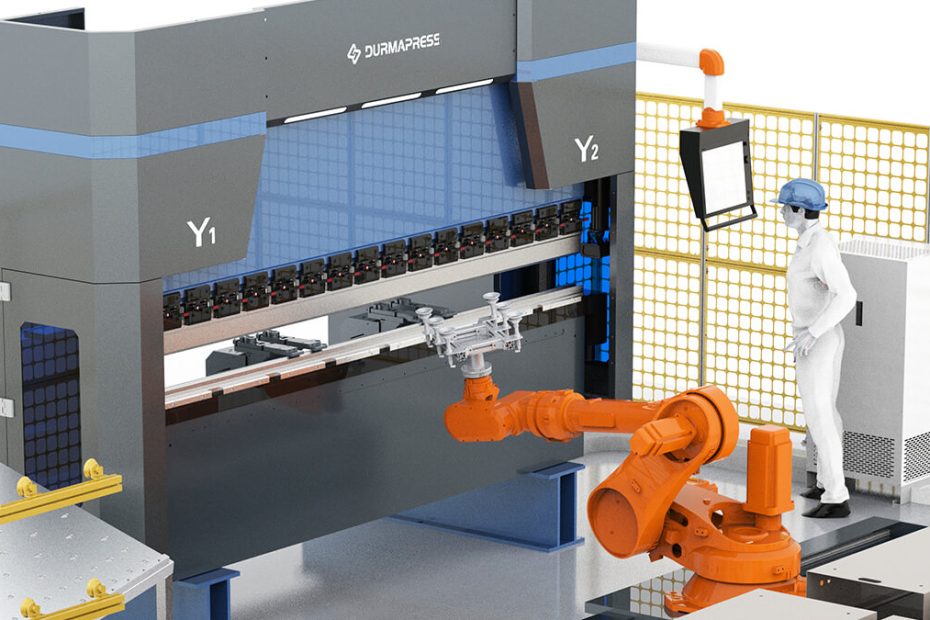

The so-called "robotic automation" refers to a mode of realizing industrial automated production with multi-joint industrial robots as the center. Compared with traditional non-standard automated production equipment, it has its own unique characteristics. Understanding these characteristics and giving full play to the advantages of robots are what non-standard automation engineers have always wanted to know. Analysis and understanding of customer needs, analysis of product production processes, decomposition of automated actions, and accumulation of engineer design experience. The accumulation of experience… Read More »What Is Involved In Robotic Automation Planning?