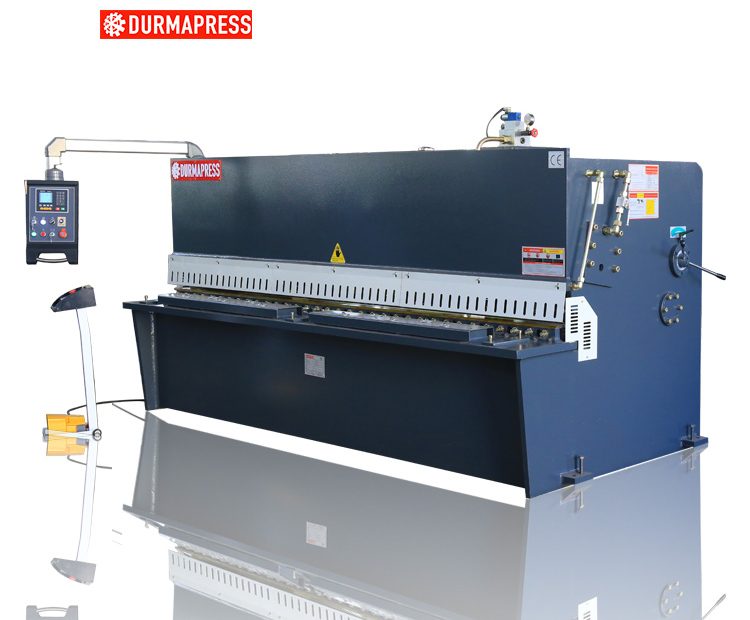

Performance and characteristics of hydraulic brake plate shearing machine

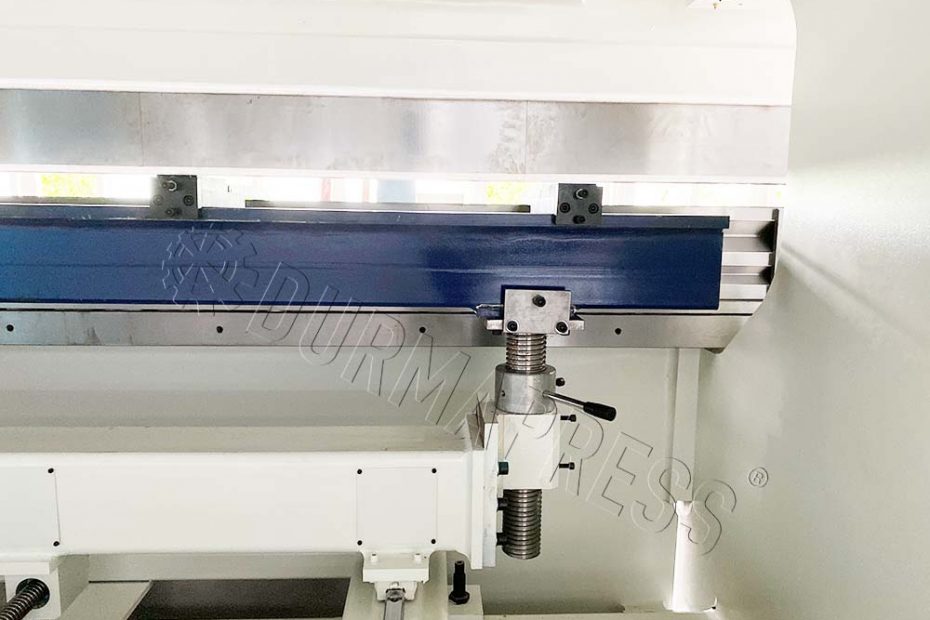

Performance and characteristics of hydraulic brake plate shearing machine: 1. Introduce foreign technology from Belgium. 2, frame, tool rest vibration eliminate stress, the whole machine welding pull hair, durable. 3, advanced integrated hydraulic system, good reliability. 4. Adopt three-point supporting rolling guide rail to eliminate supporting gap and ensure shear quality. 5, blade clearance manual or electric adjustment, fast and accurate. 6. The upper and lower blades adopt four edges to increase the service time. 7, shear Angle can be… Read More »Performance and characteristics of hydraulic brake plate shearing machine