With the rapid development of industry, higher precision profile bending equipment is needed

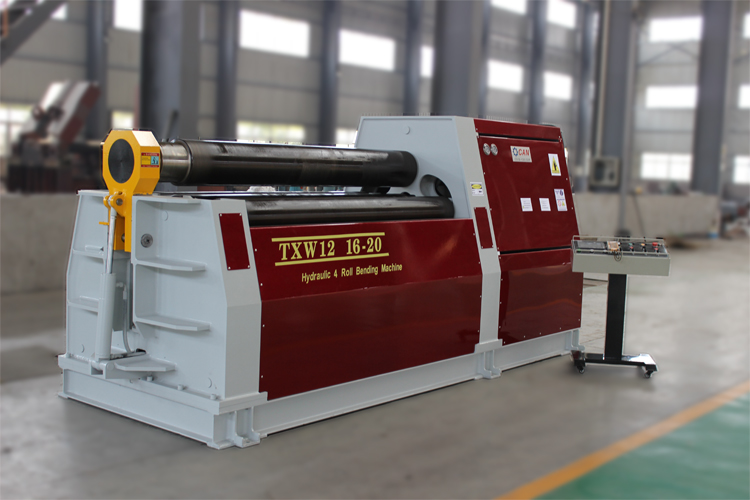

Profile bending equipment is an efficient processing equipment for bending Angle steel, channel steel, I-steel, flat steel, square steel, round steel and other special-shaped steel. Profile bending machine can roll Angle steel, channel steel,profile bending equipment I-steel and other profiles into diameter φ320-φ6000mm ring and flange of a high quality, high efficiency winding device. The structure of profile bending machine is unique, and it can be finished in one feeding process. It has the advantages of small volume, low energy… Read More »With the rapid development of industry, higher precision profile bending equipment is needed