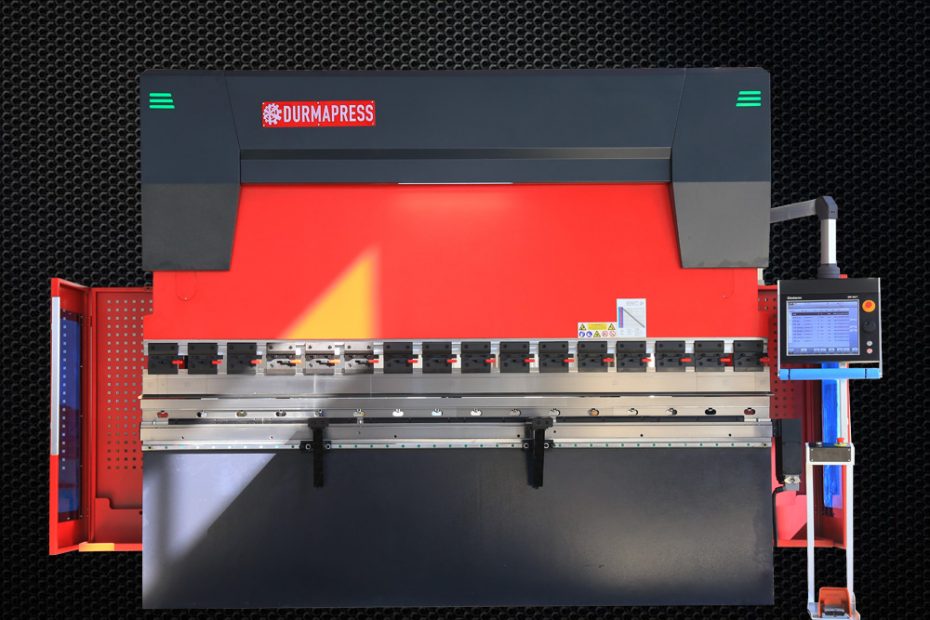

CNC bending machine price: how to extend the life of the bending machine

CNC bending machine price die in order to get long life, in the bending process should be as long as possible to adhere to continuous cutting. If the bending machine die enters and exits too frequently, the bending machine die life will be significantly shortened. This will increase thermal stress and thermal fatigue on the cutting edge. A uniform and high temperature in the cutting area is more favorable to modern carbide bending machine dies than a large shake. The… Read More »CNC bending machine price: how to extend the life of the bending machine