Numerical control vertical slotting machine advantages

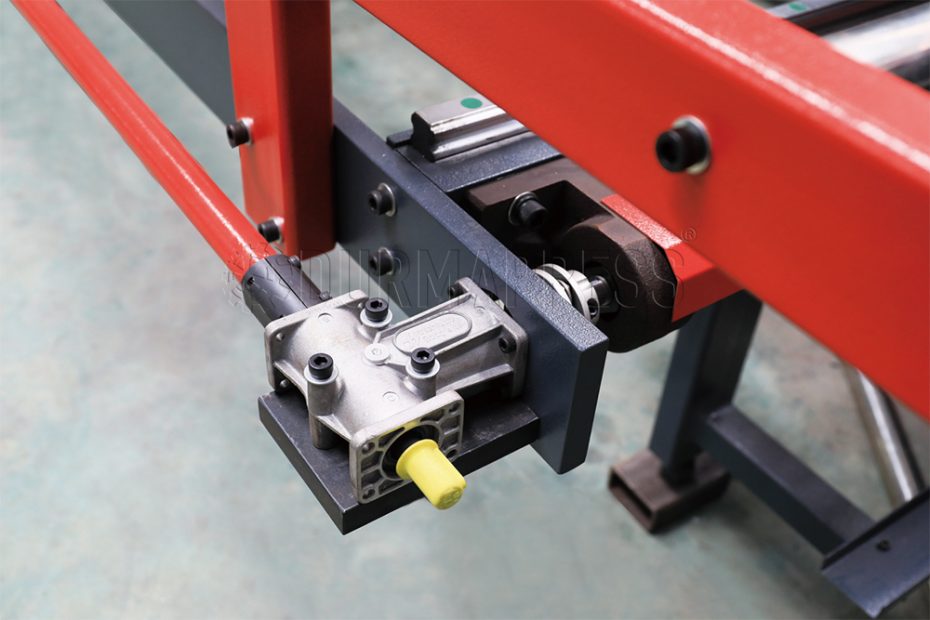

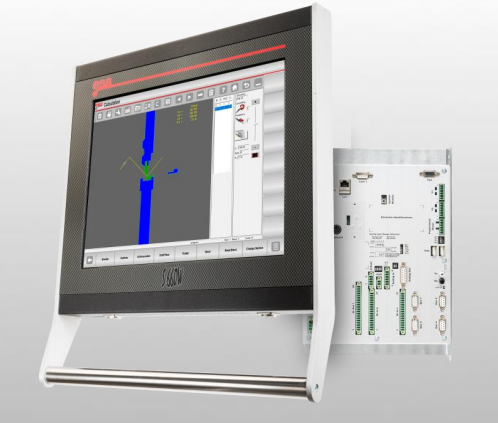

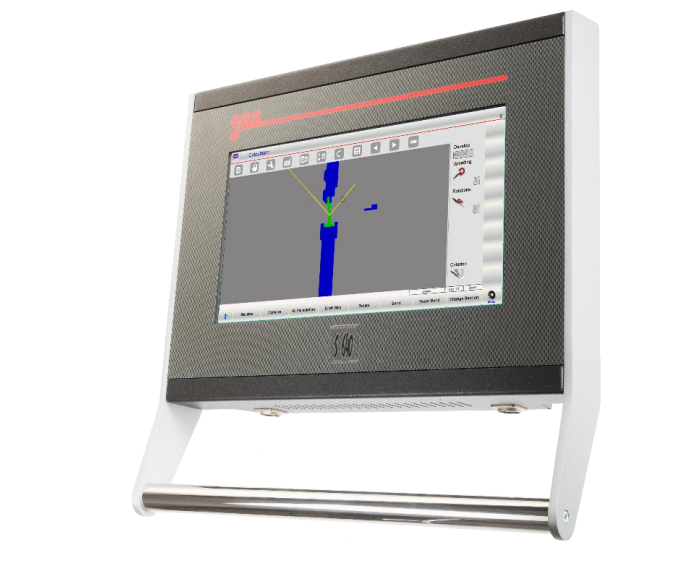

1, CNC vertical slotting machine is simple to operate: the equipment is designed for ordinary workers, strip type workpiece mortise and groove only need a simple tool, input slot parameters can automatically generate processing code, automatic processing. 2, the equipment can be processed in a wide range, suitable for processing different categories of tenon, waist round tenon, round tenon, arc tenon, spline tenon processing, double station, can be stopped for workpiece clamping, uninterrupted production, CNC vertical slotting machine, production. 3,… Read More »Numerical control vertical slotting machine advantages