How to maintain WYQ24-45 profile bending machine to make its application longer

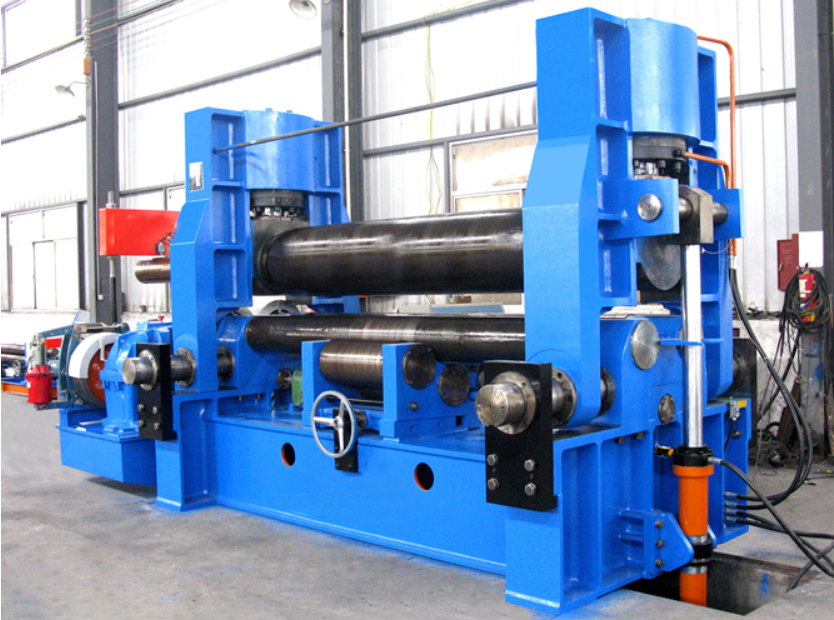

WYQ24-45 Profile bending machine for linear mode profiles roll bending machine, the machine of two side roll roll, can also be three working roll roll, the roll fixed position, roll up the clamping workpiece to prevent cross section deformation, the two sides make linear lifting movement on the corresponding roller, hydraulic control, displacement digital display, can control profile forming process, Both sides of the CNC roller and distortion correction device, is conducive to ensure the quality of asymmetric section profiles… Read More »How to maintain WYQ24-45 profile bending machine to make its application longer