How to Use DSP Laser Safety System To Protect Your Press Brake

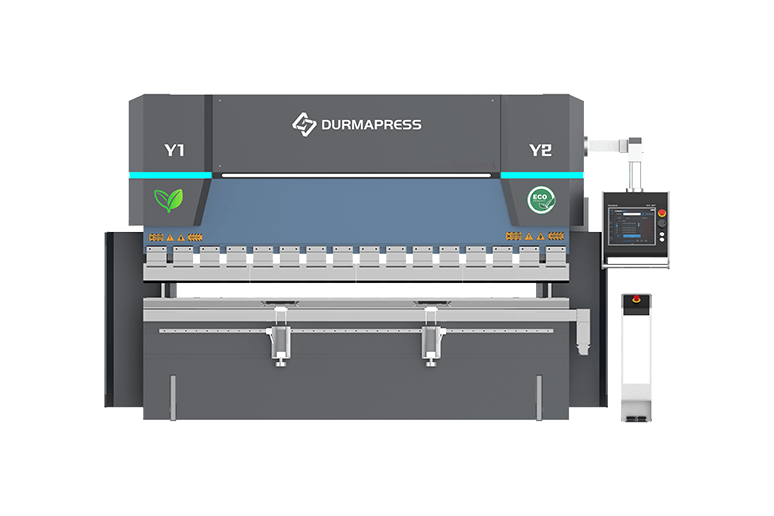

A DSP laser safety system is a safety device that protects the operator by controlling the laser beam through digital signal processing technology. It plays a vital role in bending machine operation by detecting any objects that may enter the danger zone during the bending process and stopping the machine in time to avoid accidents.