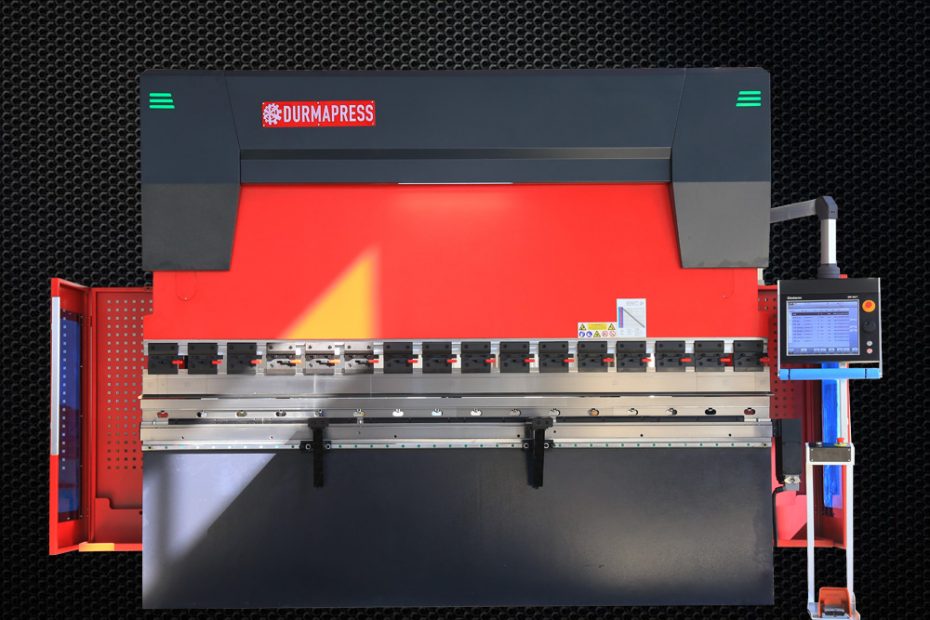

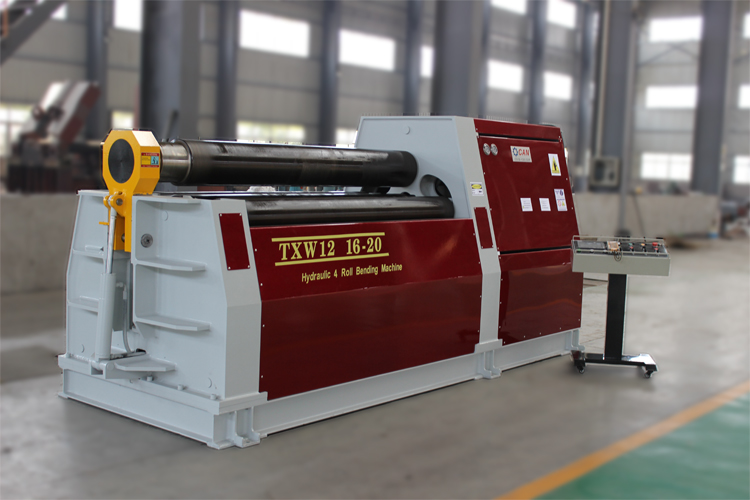

A machine capable of bending sheet metal

The principle of choosing hydraulic pump of bending sheet metal Whether variable: radial piston pump, axial piston pump, single acting vane pump is variable pump. Bending machine working pressure: piston pump pressure 31.5mpa; Vane pump pressure 6.3MPa, high pressure can reach 21MPa; Gear pump pressure 2.5mpa, high pressure after up to 25MPa. Working environment: gear pump has the best anti-pollution ability. Noise index: low noise pump internal gear pump, double acting vane pump and screw pump, double acting vane pump… Read More »A machine capable of bending sheet metal