Cnc hydraulic press brake manufacturer in industrial production is really so widely used?

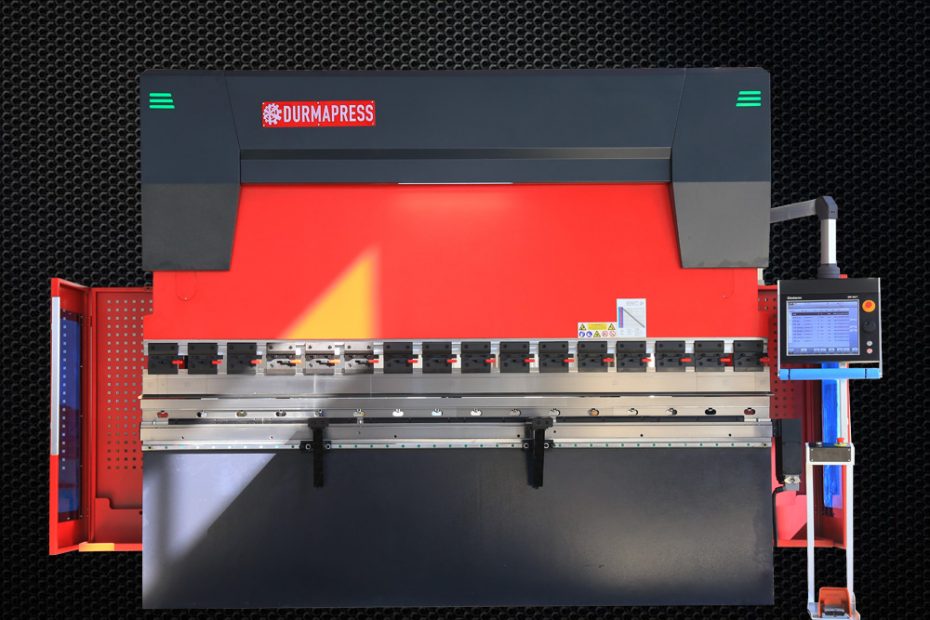

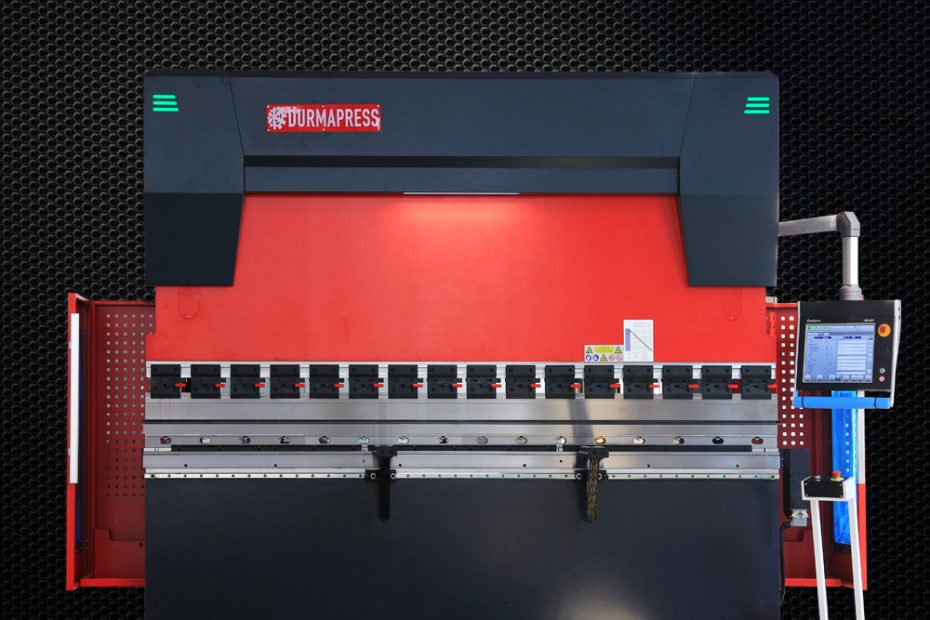

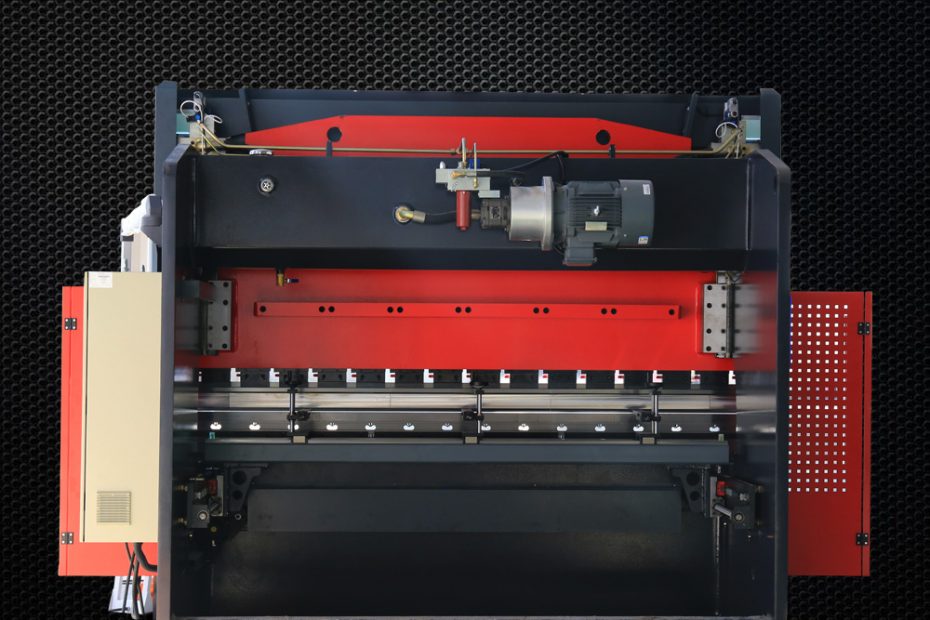

Cnc hydraulic press brake manufacturer is a kind of can be carried out on the thin plate bending machine, the structure mainly includes the bracket, workbench and clamping plate, a workbench is placed on the bracket, the workbench consists of base and the clamp, the base through the hinge and clamping plate is linked together, the base is composed of shell, the coil and plate, coil placed inside the shell of the sag, the depression at the top of the… Read More »Cnc hydraulic press brake manufacturer in industrial production is really so widely used?