Durmapress Ships Machines to Paraguay

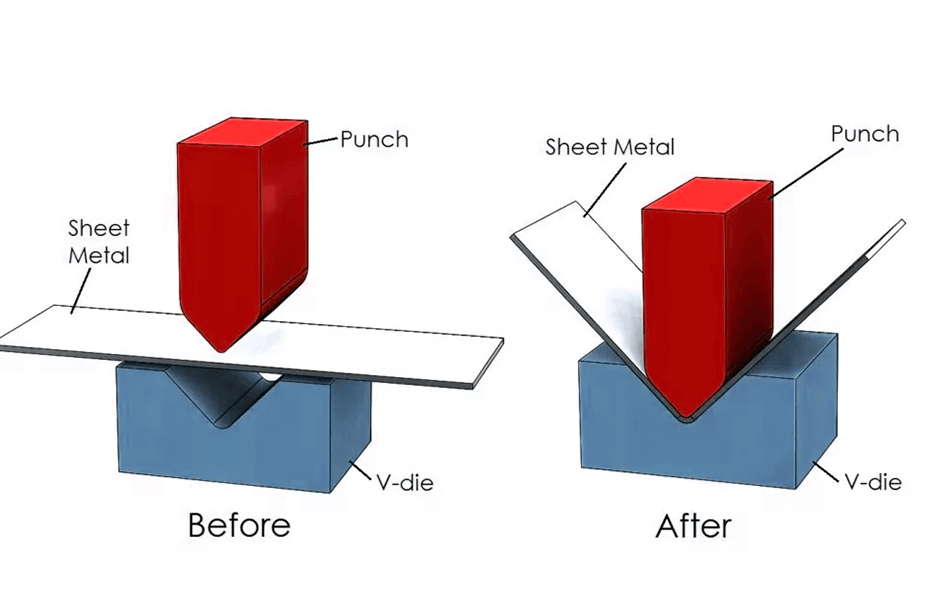

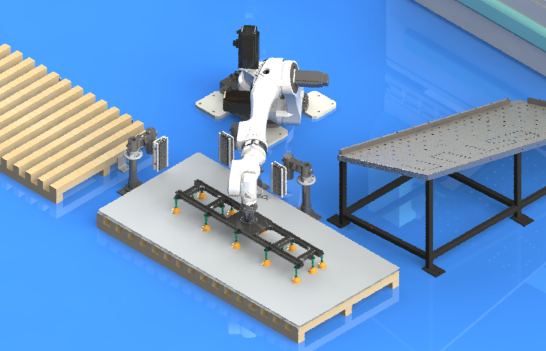

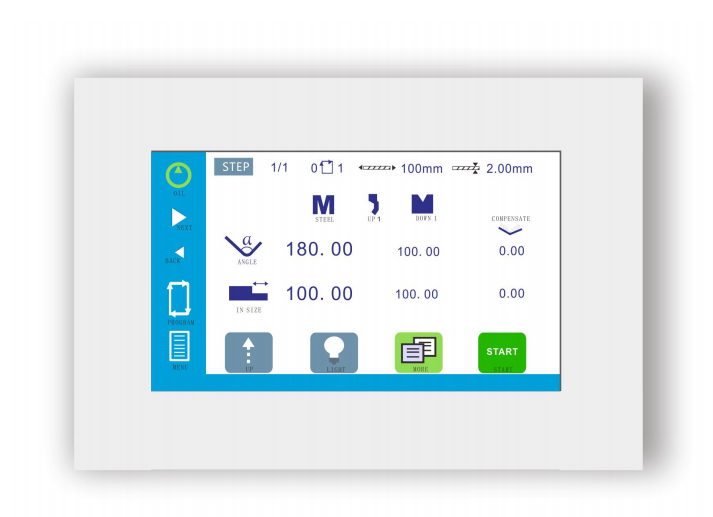

Durmapress recently shipped three of its top-notch machines, the Hydraulic Bending Machine (WC67K-100T3200), Hydraulic Swing Beam Shears (QC12Y - 4X3200), and Combined Punching and Shearing Machine (Q35Y-20), to Paraguay. This collaboration was the result of multiple communications, factory visits, and a strong willingness to cooperate from both sides, culminating in a solid trust between the parties.