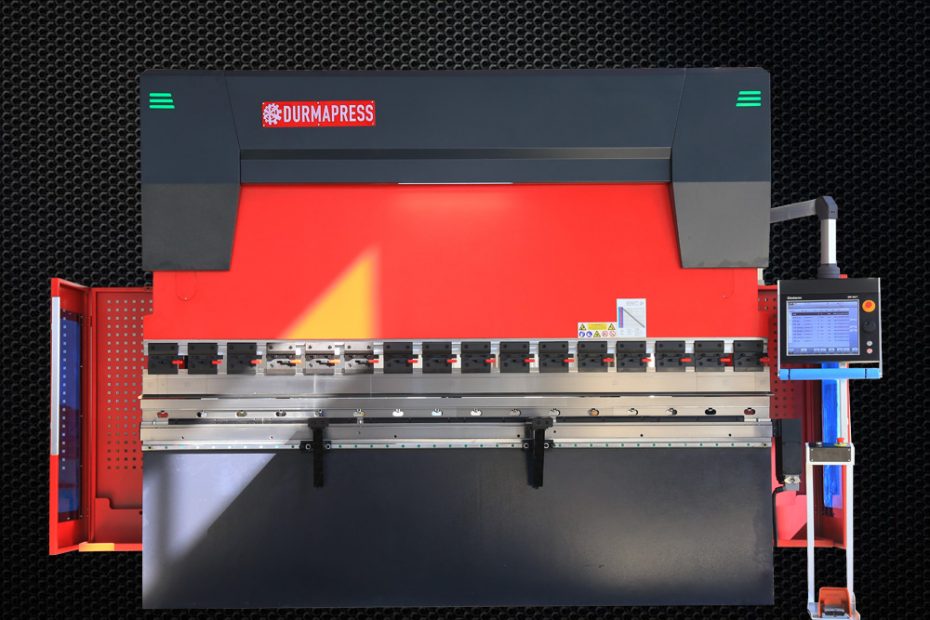

1. All steel welded structure, with sufficient strength and rigidity hydraulic sheet bending machine equipment.

2. Hydraulic upward transmission, the cylinder at both ends of the machine tool is placed on the slide block, and directly drives the sliding work.

3. Slider synchronization mechanism adopts torsional shaft to force synchronization.

4. Mechanical block structure, stable and reliable.

5. Quick adjustment of slider stroke, manual fine tuning, counter display.

6. Oblique wedge deflection compensation mechanism to ensure higher bending accuracy.

The bending machine comprises a bracket, a table and a clamping plate, the table is arranged on the bracket, the table is composed of a base and a pressure plate, the base is connected with the clamping plate through a hinge, the base is composed of a shell, a coil and a cover plate, the coil is placed in the depression of the shell, the top of the depression is covered with a cover plate.

When used, the wire is energized to the coil, and after energized, the pressure plate produces gravity, so as to achieve the clamping between the pressure plate and the base plate. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and the workpiece can be processed on the side wall.