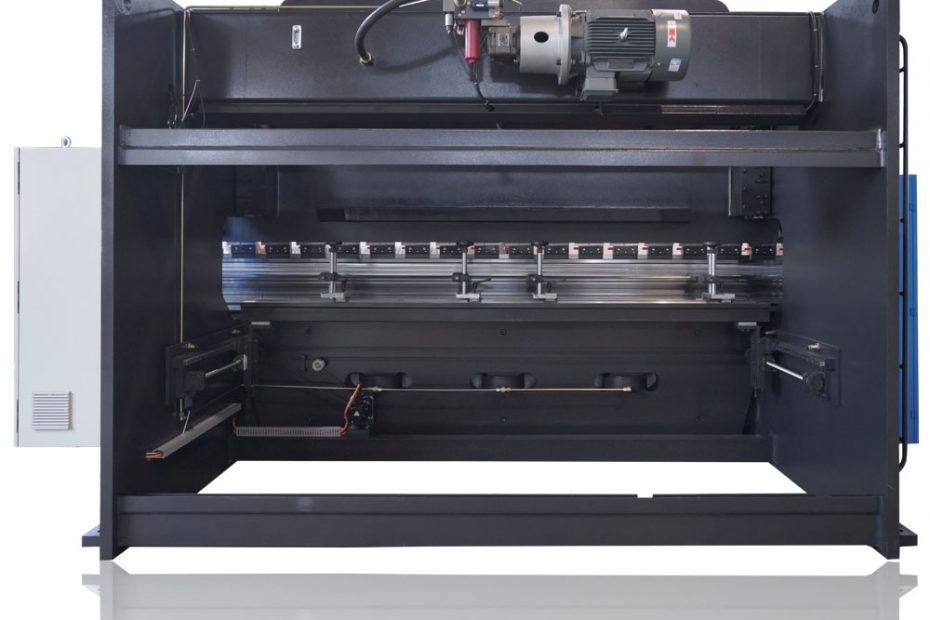

Servo press brake operating system

1. The personnel of oil press should have the corresponding qualifications and must hold the certificate. It is strictly prohibited to open and use the oil press if they do not understand the machine.

2, before the class should wear the provisions of labor protection supplies.

3. Check the following items before starting: whether the photoelectric protection device is reliable, whether the travel switch is sensitive, and whether the fastener is loose.

4, remove the work table and mold debris, adjust the working pressure, slider travel, empty running for two minutes, everything can work normally.

5. The adjusting handle on the machine has been adjusted properly when leaving the factory. It is not allowed to be adjusted by the debugging personnel

Hydraulic machine maintenance system

1, according to the lubrication requirements of the machine lubrication maintenance.

2. After the machine tool works for one year, the hydraulic oil should be released from the oil tank of the bed to clean the oil tank, and the filtered hydraulic oil should be re-filled. The oil quantity should be determined at the 3/4 height of the oil mark.

3. The oil filter network on the suction pipe must be cleaned or washed regularly.

4. Check whether the handle, twist and key are damaged regularly.

5. The motor must be kept clean, and the air inlet net cover of the motor should always be well ventilated and not blocked.

6. Lubricate and scrub the machine tools 10 minutes before work every day.

7. It is strictly prohibited for non-operators to operate the equipment. People must leave the machine and stop at ordinary times.