Preface

In this article, we will discuss the challenges and considerations for the transportation and installation of press brakes. As precision machinery, its transportation and installation must be carefully planned and executed to ensure smooth use of the equipment and avoid damage. First, the importance of transportation and installation is clear. press brakes play a key role in production, but improper transportation and installation will damage the precision of the equipment, and even lead to damage, bringing economic losses. Therefore, adequate preparation is required before transportation to evaluate the transportation route, tools and installation site. Ensure that all the links meet the requirements before proceeding with the actual operation. During transportation, pay attention to equipment fixation and protection. Use specialized devices and anti-vibration materials to prevent equipment displacement or damage. After arriving at the site, check and debug the equipment. Ensure that the site meets the requirements, assemble and debug according to the instruction manual, pay attention to the firm connection of components and correct electrical wiring. At the same time, train the operators to master the operation and maintenance knowledge to improve productivity and safety. In short, the transportation and installation of the press brake need to be carefully planned and executed to ensure the smooth use of the equipment and create economic benefits.

Preparation before transportation

Before transporting the machine, a detailed assessment of the size and weight of the machine is first required in order to select the appropriate lifting equipment. This step is crucial as improper selection may lead to safety issues during lifting and may even result in damage to the equipment. It is therefore important to carefully measure the length, width, height and weight of the machine to ensure that the chosen lifting equipment is capable of handling the weight of the machine and that there is sufficient space for maneuvering.

After evaluating the dimensions and weight of the machine, the intended transportation route next needs to be carefully examined to identify any potential obstacles that may exist. This includes, but is not limited to, low bridges, tight curves, heavily trafficked roadways, and other factors that may affect the smooth flow of transportation. Identifying these obstacles in advance and developing appropriate countermeasures can effectively avoid delays or accidents during transportation.

Finally, before transporting the machine, it is important to ensure that the machine is securely fastened to the transport vehicle. The purpose of this step is to ensure that the machine does not move or tilt during transportation, thus maintaining transportation stability. In order to achieve this, appropriate fixings such as straps, brackets and padding need to be used to ensure that the weight of the machine is evenly distributed. The firmness of the fixings should also be checked to ensure that the machine does not come loose or fall off throughout the transportation process. By taking these measures, possible risks during transportation can be minimized, ensuring that the machine reaches its destination safely and smoothly.

Durmapress' unique wooden crate transportation

Durmapress is known for its unique transportation features, one of the most notable of which is its wooden crate transportation service.Durmapress uses high-quality wooden crates to ensure the safety and stability of goods during transportation. These crates are carefully designed and manufactured to withstand the bumps and shocks of long-distance transportation, thus minimizing the risk of cargo damage.

The materials used for the crates are chosen in accordance with strict environmental standards to ensure that there is no negative impact on the environment during transportation. In addition, Durmapress offers customized wooden crate solutions to meet the specific needs of different customers and goods. Whether it is large machinery or precision instruments, Durmapress can provide the right size and structure of wooden crates to ensure the safety of the goods during transportation.

In addition to the high quality of the crate itself, Durmapress also focuses on the detailed management during transportation. They use an advanced logistics management system to monitor the transportation status of the goods in real time, ensuring that the goods arrive at the destination on time. At the same time, Durmapress also provides door-to-door services, from crating, transportation to unloading, every step of the process is strictly controlled by professionals to ensure that customers enjoy a hassle-free transportation experience.

Transportation Considerations

When choosing the mode of transportation, the specific characteristics and requirements of the machine must be fully considered to ensure a safe and efficient transportation process. First, choose the most appropriate means of transportation, such as a flatbed truck or trailer, based on the size, weight and shape of the machine. Flatbed trucks are suitable for large or heavy equipment as they provide a stable carrying platform, while trailers are suitable for longer or irregularly shaped items and can flexibly adapt to a variety of transportation needs.

Next, road conditions along the transportation route must be carefully evaluated, including the smoothness of the road, traffic conditions, and weather conditions that may be encountered. All of these factors can have a significant impact on the transportation process. In order to minimize possible damage during transportation, appropriate protective materials, such as air cushions, foams and wooden frames, should be selected to ensure that the machine is adequately protected during transportation. In addition, reasonable arrangement of transportation time to avoid peak hours and bad weather is also an important measure to ensure smooth transportation. By comprehensively considering these factors, the most suitable transportation method can be effectively selected to ensure that the machine reaches its destination safely and efficiently.

Safety measures during transportation

During the process of machine transportation, appropriate lifting equipment must be used to ensure that the machine remains firm during transportation. This not only helps prevent accidental damage to the machine during transportation, but also ensures safe transportation. At the same time, the transportation team needs to pay close attention to road conditions and avoid bumpy roads as much as possible to reduce the vibration and impact of the machine during transportation. It is also vital to take the necessary protective measures, such as using dust covers and moisture-proof materials, to prevent dust and humidity from adversely affecting the machine. These measures will help maintain the performance of the machine and extend its service life.

Assessment and preparation of the installation site

To ensure that the event runs smoothly, you first need to ensure that the venue is spacious enough to accommodate all participants and equipment. At the same time, carefully clear any obstacles in the path of the event to ensure that access is clear and unobstructed to avoid any surprises.

Next, the ground level of the venue is meticulously checked to ensure that there are no potholes or bumps that could interfere with the event or pose a safety hazard. The availability of electricity and gas supply also needs to be checked to ensure that they can meet the needs of the event. If the ground or facilities are found to have safety hazards, necessary reinforcement measures must be carried out to ensure the safety and smoothness of the whole event process.

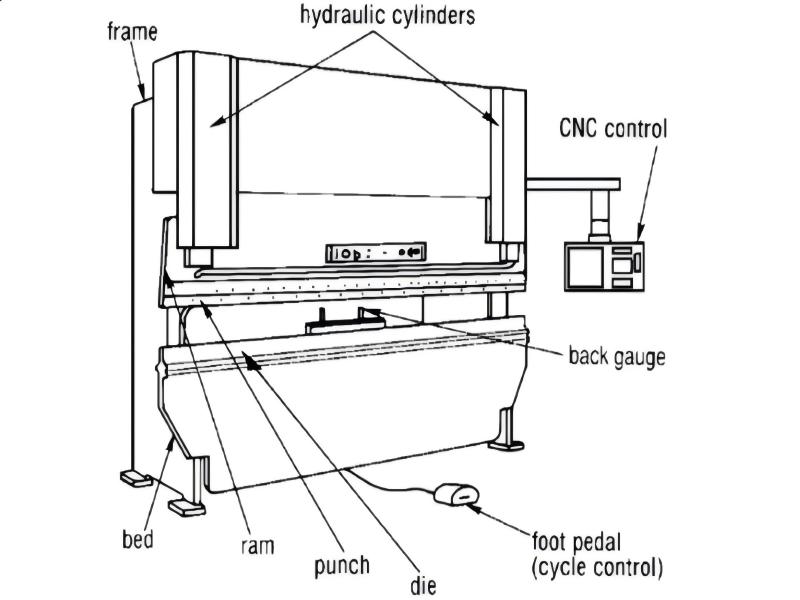

Installation process of the press brake

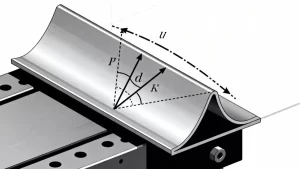

In order to ensure the efficiency and accuracy of the press brake, you first need to make sure that the venue is level in order to avoid any unnecessary wobbling or tilting of the equipment during the working process. Next, carefully align the press brake to ensure that it remains parallel to the ground or other reference plane, thus ensuring the accuracy of the bent parts.

During the preparation phase of the equipment, make sure to securely connect the electrical and gas sources, ensuring that all connectors and wiring meet safety standards and avoiding any possible risk of electrical or gas leakage. Subsequently, secure the press brake in a suitable position to ensure its stability and safety. Next, initial setup and calibration work is carried out, which involves adjusting the bending angle, speed, and other relevant parameters to ensure that the equipment is able to operate according to the intended specifications and requirements. These meticulous preparations ensure that the press brake achieves optimal performance in the production process, increasing productivity and product quality.

Testing and Calibration

Before starting up and commissioning the equipment, it is first necessary to double-check all electrical connections and air connections to ensure that they are all firm and reliable, and that nothing is loose or damaged. This step is critical, as any unstable power or gas source may cause the equipment to operate improperly or even malfunction or have a safety incident.

Next, the equipment is functionally tested and adjusted. This involves a thorough check of the operation of the various components and systems to ensure that they are working properly. During testing, special attention should be paid to the response time and operational stability of the equipment so that potential problems can be identified and resolved in a timely manner. According to the test results, make necessary adjustments to the equipment to ensure that it achieves the best working condition.

Finally, record all the test results in detail. This data includes not only the operating parameters of the equipment, but also any problems found and their solutions. These records ensure that the accuracy and performance of the equipment is continually monitored and verified. At the same time, these records provide valuable information and references for future maintenance and troubleshooting.

Safety Precautions

Always wear personal protective equipment, such as helmets, protective eyewear, protective gloves, protective shoes, etc., to ensure your safety when performing various tasks or operations. At the same time, strictly follow the safety instructions and operate in accordance with the prescribed steps and methods, do not change or simplify the process at will.

Maintaining a high level of safety awareness is the key to preventing accidents. Whether in the workplace or in daily life, you should always be alert to potential safety hazards, pay attention to your surroundings, and promptly identify and deal with problems that may cause accidents. Through regular safety training and education, we can improve our own knowledge and understanding of safety, so as to effectively avoid all kinds of accidents and ensure the safety of our own lives and the lives of others.

Conclusion

Through precise planning and strict implementation, we can ensure the safe transportation and installation of press brakes and extend the service life of the equipment. Specifically, we need to carefully inspect the equipment before transportation to ensure that all parts are intact and properly packaged to prevent collision or damage during transportation. During transportation, choose the appropriate transportation tools and routes to ensure that the equipment is transported smoothly, avoiding violent bumps and vibrations. After arriving at the destination, install the equipment carefully according to the equipment manual and installation guide to ensure that all connecting parts are firm and reliable. In addition, regular maintenance and inspection of the equipment, timely detection and resolution of potential problems is also the key to ensure the long-term stable operation of the equipment. Through these measures, we can maximize the service life of the press brake and ensure its efficient operation.

About Us

Durmapress specializes in designing, manufacturing and selling various metal processing equipment, including bending machines, shears, punches, laser cutting machines, etc. The company was founded in 2000. With years of experience and technology accumulation. DurmaPress has become one of the well-known brands in China's metal processing machinery industry.

Contact Us

Recent Posts

Categories

Follow Us

Weekly New Video

Contact us for more information

If you have any information about our products, please contact us and we will reply within 24 hours.