importance of metal processing machinery in industry

Definition and Usage

A press brake is a key piece of equipment used to bend sheet metal into various shapes. It is one of the indispensable equipment in the manufacturing process as it bends the sheet metal into predefined angles and shapes by applying pressure. press brakes play an important role in metal forming, processing and manufacturing. They can accurately control the bending angle and shape to meet various complex design needs.

Key Features and Functions

One of the main features of a press brake is its high precision and strength. This allows it to handle sheet metal of various thicknesses and maintain consistent quality during the bending process. Modern press brakes are usually equipped with a numerical control (CNC) system that manages the bending process through precision control software, ensuring that each workpiece meets predetermined specifications and requirements. CNCs not only increase the efficiency of the process, but also reduce human error and improve product consistency. In addition to this, the press brake is equipped with a variety of features, including multi-axis control, automatic mold change, angle detection and compensation, which further enhances its operational flexibility and machining accuracy.

Common Applications and Industries

Press brakes have a wide range of applications in several industries. The automotive industry utilizes press brakes to produce body parts and frames; the aerospace industry uses them to make structural components for aircraft; the appliance industry relies on press brakes to make housings and internal structural components; and the construction industry uses them to process building components and decorative materials. The versatility and efficiency of the press brakes make them indispensable in these industries for a wide range of complex and high-precision machining needs.

Durmapress Products

Durmapress' WE67K hydraulic press brake is one of the most highly acclaimed products on the market. With its robust steel-welded construction, the machine offers excellent strength and rigidity and is capable of withstanding long hours of intense work without deformation. Its CNC control system provides high precision bending control, ensuring quality and consistency in every workpiece.

dobrador de painéis

Definition and Usage

A panel bender is used to bend sheet metal into complex shapes and angles, usually for manufacturing precision components. It performs particularly well with larger sizes and complex shapes of sheet metal.

Key Features and Functions

The panel bender is highly automated and intelligent. It enables fast changeovers and efficient production, reduces human intervention and improves production consistency. The machines are often equipped with advanced control systems that automatically adjust the bending parameters to ensure a high standard of accuracy and quality for each part.

Common Applications and Industries

Panel press brakes are widely used in electronic equipment housings, metal furniture, air conditioner housings, and other fields. These industries require high-precision and high-efficiency bending processes to meet the demands of complex designs and mass production.

Durmapress Products

Panel press brakes are widely used in electronic equipment housings, metal furniture, air conditioner housings, and other fields. These industries require high-precision and high-efficiency bending processes to meet the demands of complex designs and mass production.

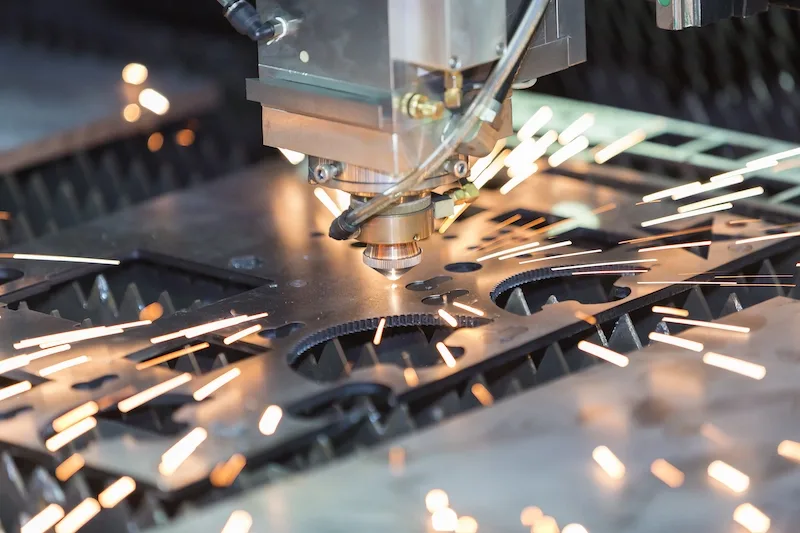

Definition and Usage

The laser cutting machine utilizes a high-energy laser beam to cut metal materials without contact and with high precision. It can cut various metal materials quickly and precisely, and is one of the indispensable equipments in modern manufacturing industry.

Key Features and Functions

Laser cutting machines are known for their high precision and high-speed cutting capabilities. The equipment is capable of handling complex shapes and details, reducing material waste and improving processing efficiency. Modern laser cutting machines are often equipped with advanced control systems and fiber lasers to further enhance cutting quality and speed.

Common Applications and Industries

Laser cutting machines are widely used in sheet metal processing, automotive manufacturing, aerospace and electronics industries. These industries require high-precision and high-efficiency cutting processes for complex designs and high-volume production.

Durmapress Products

Durmapress' laser cutting machines utilize advanced laser technology to ensure high precision and efficient cutting results. The machines are equipped with an intelligent control system that automatically adjusts the cutting parameters to optimize the process and improve productivity and product quality.

Definition and Usage

A shearing machine is used to cut sheet metal, usually to prepare raw materials or for preliminary processing. It applies shearing force to cut the metal sheet into the required size and shape, and is a common equipment in the metal processing process.

Key Features and Functions

Shearing machines are characterized by high cutting force, ease of operation and high cutting accuracy. The equipment is usually equipped with an automated control system that enables precise cutting and efficient production. Its sturdy mechanical structure and hShearing machines are characterized by high cutting force, ease of operation and high cutting accuracy. The equipment is usually equipped with an automated control system that enables precise cutting and efficient production. Its sturdy mechanical structure and high-strength blades ensure stable operation and high-quality cutting for a long time.

Common Applications and Industries

Shears are widely used in the metal fabrication, automotive manufacturing and construction industries. These industries require efficient and accurate cutting processes to meet a variety of production needs and specifications.

Durmapress Products

Durmapress shears offer powerful cutting capabilities and efficient operating performance. Featuring rugged mechanics and high-precision control systems, the machines are ideal for metal fabrication, as they are capable of handling a wide range of sheet metal thicknesses and sizes.

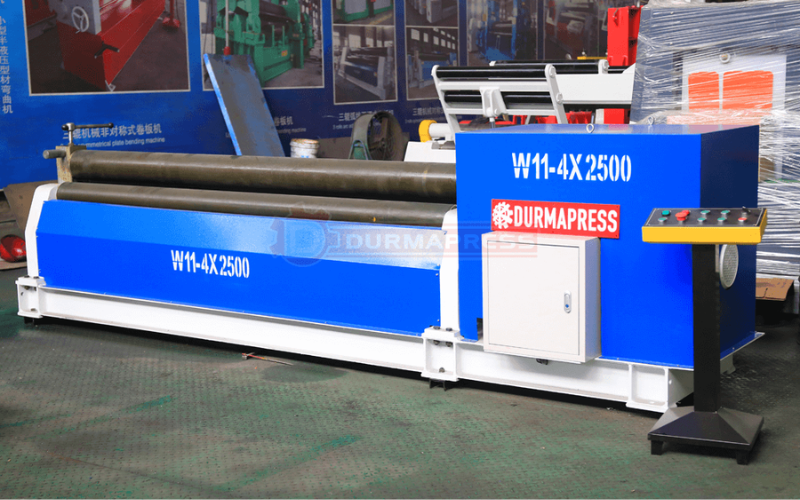

Definition and Usage

The Rolling Machine is used to roll sheet metal into cylinders or other curved structures. By rolling, it is capable of bending flat sheet metal into the desired curvature and shape, and is a common piece of equipment used in the manufacturing process.

Key Features and Functions

Rolling machines have high-strength, adjustable rollers that are capable of handling plates of varying thicknesses. The machines are often equipped with automated control systems that allow for precise control of the curling process, ensuring quality and consistency of each workpiece.

Common Applications and Industries

Rolling machines are widely used in boiler manufacturing, chemical containers, and machinery manufacturing. These industries require high-precision, high-strength curling processes for a variety of complex shapes and sizes.

Durmapress Products

Durmapress plate rollers are known for their consistent performance and versatility. Featuring robust mechanics and high-precision control systems, the machines are capable of handling a wide range of metal coiling needs, ensuring high quality and efficient production.

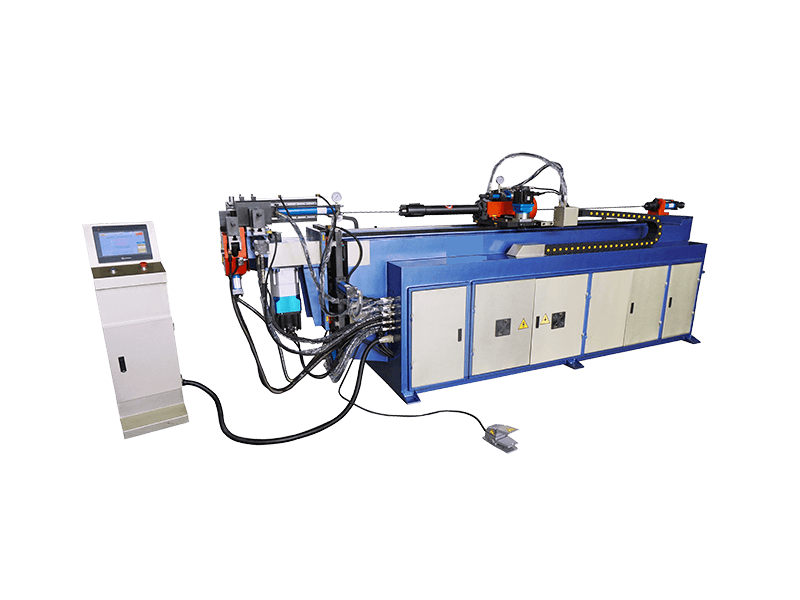

Definition and Usage

CNC Pipe bending machine is used for bending all kinds of metal pipes. It accurately controls the bending angle and shape through the CNC system, realizing high-precision and high-efficiency processing, and is an important equipment in the field of pipe processing.

Key Features and Functions

CNC Pipe bending machines are equipped with high-precision bending capability and automated control systems, capable of handling complex bending shapes and a wide range of pipe specifications. The machines are usually equipped with multi-axis control, automatic feeding and multi-station switching to ensure efficient and accurate processing. The CNC system can store multiple machining programs for quick switching to adapt to different production needs.

Common Applications and Industries

CNC Pipe bending machines are widely used in automotive manufacturing, aerospace, shipbuilding, fitness equipment and furniture manufacturing. These industries require high-precision, high-efficiency tube bending processing for complex designs and high-volume production.

Durmapress Products

CNC Pipe bending machines offer high precision and reliability. The machines utilize advanced CNC and multi-axis control technology and are capable of handling a wide range of tubes with complex bending shapes and sizes. Their automated features and high production capacity make them ideal for a wide range of industries, ensuring a high quality and efficient process.

Definition and Usage

Profile bending machines are used for bending various metal profiles such as steel tubes and aluminum profiles. By bending, it is able to bend straight profiles into desired angles and shapes, and is a common piece of equipment used in the metal processing process.

Key Features and Functions

Profile bending machines are flexible and adaptable, capable of handling profiles of different cross-sections. The machines are usually equipped with an automated control system that allows precise control of the bending process, ensuring quality and consistency of each workpiece.

Common Applications and Industries

Profile bending machines are widely used in industries such as construction, bridges, marine and automotive manufacturing. These industries require efficient and accurate bending processes to meet a variety of design needs and specifications.

Durmapress Products

Durmapress Profile bending machines are known for their high precision and great adaptability. Featuring robust mechanics and high-precision control systems, the machines are able to handle a wide range of profile bending needs, making them ideal for efficient production.

Definition and Usage

The V Groover Machine is used to cut V-shaped grooves in sheet metal for subsequent bending and forming. With precise cutting, it creates a predetermined groove shape in the sheet metal and is a common piece of equipment used in the manufacturing process. This type of equipment can effectively improve processing efficiency and precision during the manufacturing process, ensuring smooth bending and forming operations.

Key Features and Functions

V-groove machines are characterized by high grooving accuracy and ease of operation. The machines are usually equipped with an automated control system that precisely controls the cutting process to ensure the quality and consistency of each workpiece. In addition, V groove machines are highly adaptable as they are suitable for a wide range of plate thicknesses. Its robust mechanical structure and efficient tooling system ensure stable performance and high-quality grooving results over a long period of time.

Common Applications and Industries

V grooving machines are widely used in furniture manufacturing, building decoration and elevator manufacturing. These industries require high-precision and high-efficiency grooving to meet the demands of complex designs and mass production. In furniture manufacturing, the V-groove machine is used to create intricate decorative edges and seams; in architectural decoration, it is used to create beautifully crafted decorative metal panels; and in elevator manufacturing, it is used to machine elevator panels and other critical components.

Durmapress Products

Durmapress' V-groove machines are well known in the market for their excellent performance and high reliability. The machines are equipped with robust mechanical structure and high-precision control system to ensure long time stable operation and high quality cuts.Durmapress V-groove machines are equipped with advanced automation features, such as automatic alignment and cutting parameter adjustments, which greatly improve the productivity and machining accuracy. With Durmapress V-groove machines, users are able to realize more complex and higher quality metal processing, providing an ideal solution for various industries.

Definition and Usage

The Hydraulic Ironworker is a multifunctional machine capable of performing a variety of processing operations such as shearing, punching and bending. It is commonly used in the metal working field as it delivers strong pressure through the hydraulic system to achieve efficient and high-precision machining.

Key Features and Functions

Hydraulic Ironworkers are easy to operate and have a wide range of applications, capable of handling a wide variety of metal materials. The equipment is usually equipped with a multifunctional worktable and a variety of tool heads, enabling quick switching between different processing operations to meet diversified production needs. Its hydraulic system provides stable pressure and efficient processing capability, ensuring quality and consistency of each workpiece.

Common Applications and Industries

Hydraulic Ironworkers are easy to operate and have a wide range of applications, capable of handling a wide variety of metal materials. The equipment is usually equipped with a multifunctional worktable and a variety of tool heads, enabling quick switching between different processing operations to meet diversified production needs. Its hydraulic system provides stable pressure and efficient processing capability, ensuring quality and consistency of each workpiece.

Durmapress Products

Durmapress Hydraulic Ironworkers are known for their efficient versatility and robust mechanical construction. Equipped with advanced hydraulic systems and multifunctional tables, the machines are capable of handling shearing, punching and bending operations on a wide range of metal materials. Their high efficiency and accuracy make them highly competitive in the market, meeting the diverse needs of major industries.

Plasma Cutting Machine

Definition and Usage

The plasma cutting machine utilizes a high-temperature plasma arc to cut metal materials. It is capable of cutting metal sheets of various thicknesses quickly and accurately, and is one of the common equipments used in metal processing.

Key Features and Functions

The plasma cutting machine cuts metal sheets of various thicknesses and materials with high cutting speeds and a wide range of applications. The equipment is usually equipped with an advanced control system that can automatically adjust the cutting parameters to ensure high quality and efficient cutting results. Plasma cutting technology can realize high-precision cutting, reduce material waste and improve productivity.

Common Applications and Industries

Plasma cutting machines are widely used in the metalworking, automotive, shipbuilding, machinery manufacturing and construction industries. These industries require efficient and accurate cutting processes for complex designs and mass production.

Conclusão

Future Trends in Metalworking Machinery

With the continuous progress of technology, the future trend of metal processing machinery will be towards more intelligent, efficient and multi-functional development. The popularization of automation and CNC technology will further enhance processing precision and efficiency; the application of intelligent manufacturing and industrial internet will realize remote monitoring and intelligent maintenance of equipment, improving the service life and productivity of the equipment.With its excellent product quality and technological innovation, Durmapress will continue to lead the industry and provide customers with more efficient and reliable metal processing solutions.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.

-300x169.jpg)