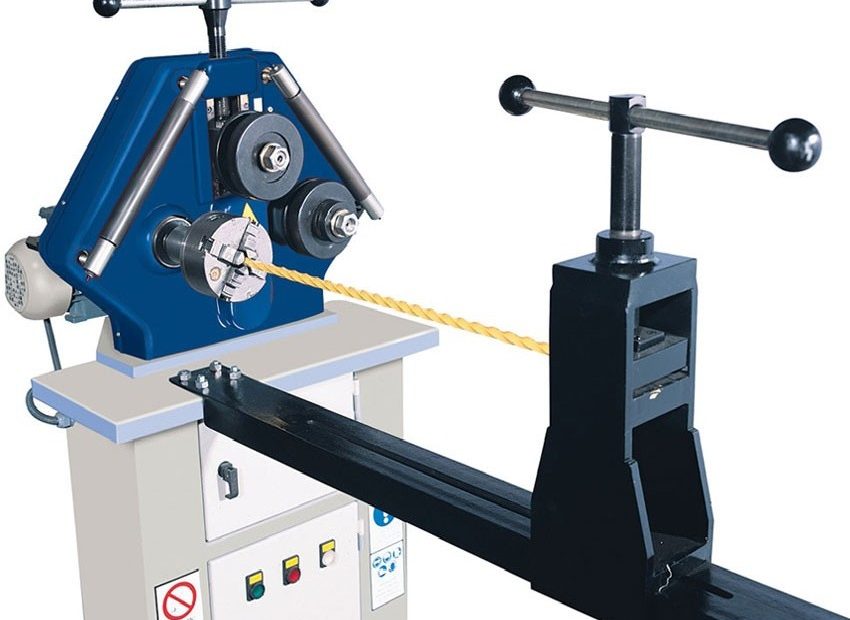

Hydraulic three - roller symmetrical bending machine using skills

Preparation before starting: check whether all parts are correct, fastening screws (caps) shall not be loose Hydraulic three - roller symmetrical bending machine. The brake should be normal and reliable. The distance of the drum shall be adjusted strictly according to the thickness of the plate, and overload operation shall not be allowed. Can not roll the workpiece which is higher than the mechanical performance defined category. Overdetail in operation: it is necessary to put the workpiece safely, check each… Ler mais "Hydraulic three - roller symmetrical bending machine using skills