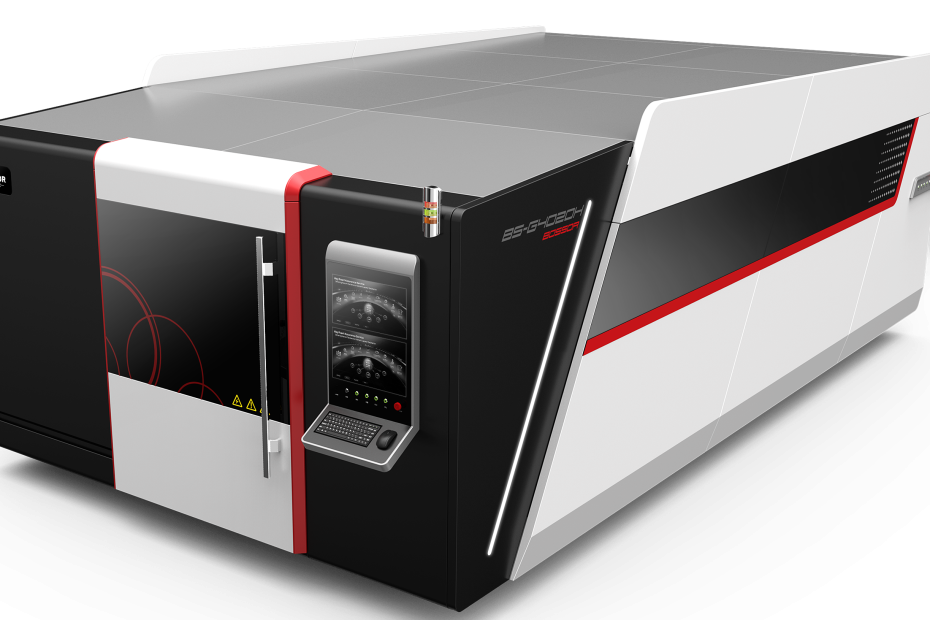

Expanding Laser Cutting Applications: Key Highlights and Competitive Landscape of Domestic Laser Cutting Equipment

Laser cutting technology is rapidly advancing, finding applications in a growing number of industries. This expansion is driven by the technology's precision, efficiency, and versatility. In the domestic market, the landscape for laser cutting equipment is highly competitive and fragmented, with numerous manufacturers vying for market share.