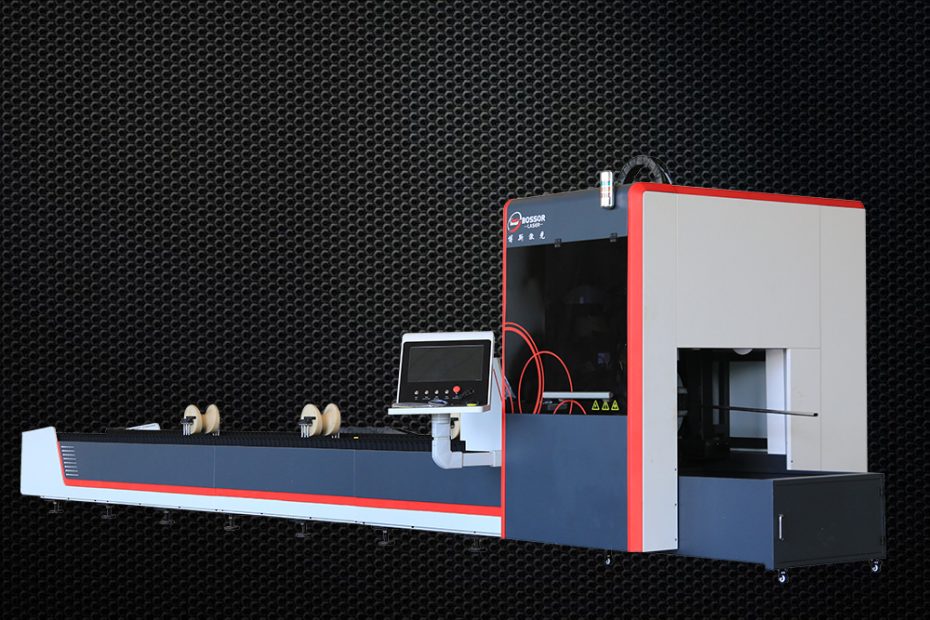

Half-year maintenance of the Full Covered Fiber Laser Cutting Machine with Exchange Table (or after 2000 hours of operation)

1) Check whether there is any corrosion phenomenon in the cooling water pipe of the laser head. If there is, it should be processed or replaced in time. 2) Check whether the fuel tank of the excitation power supply is leaking 3) Check whether the high-voltage cable is damaged Full Covered Fiber Laser Cutting Machine with Exchange Table . 4) Check and clean the inside of the laser cavity and all the lensesincluding the front window mirror tail mirror reflector… Ler mais "Half-year maintenance of the Full Covered Fiber Laser Cutting Machine with Exchange Table (or after 2000 hours of operation)