Máquina de cisalhamento

Providing High-quality Hydraulic Shearing Machines in China

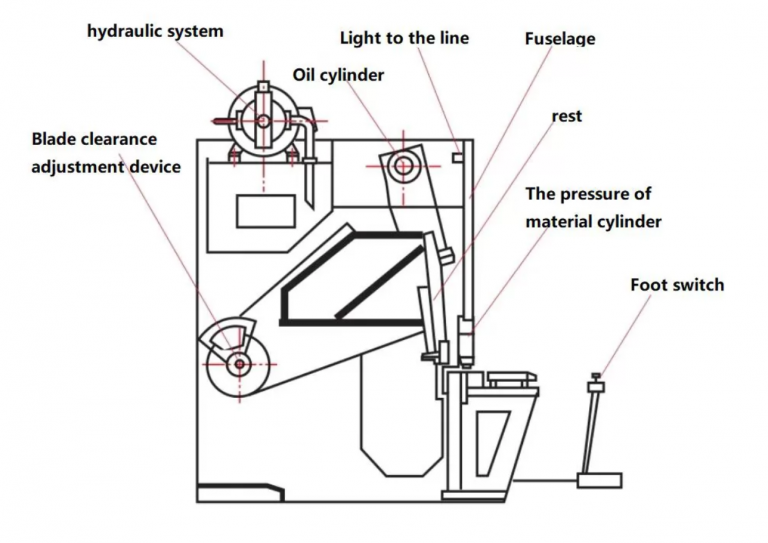

The hydraulic shearing machine is a precision cutting tool designed for metalworking applications that require high quality cuts. It features a moving upper blade and a fixed lower blade, which work together to apply a shearing force that cuts through metal plates of various thicknesses. The machine is equipped with an automatic gap adjustment system, ensuring precise cuts with minimal material waste.

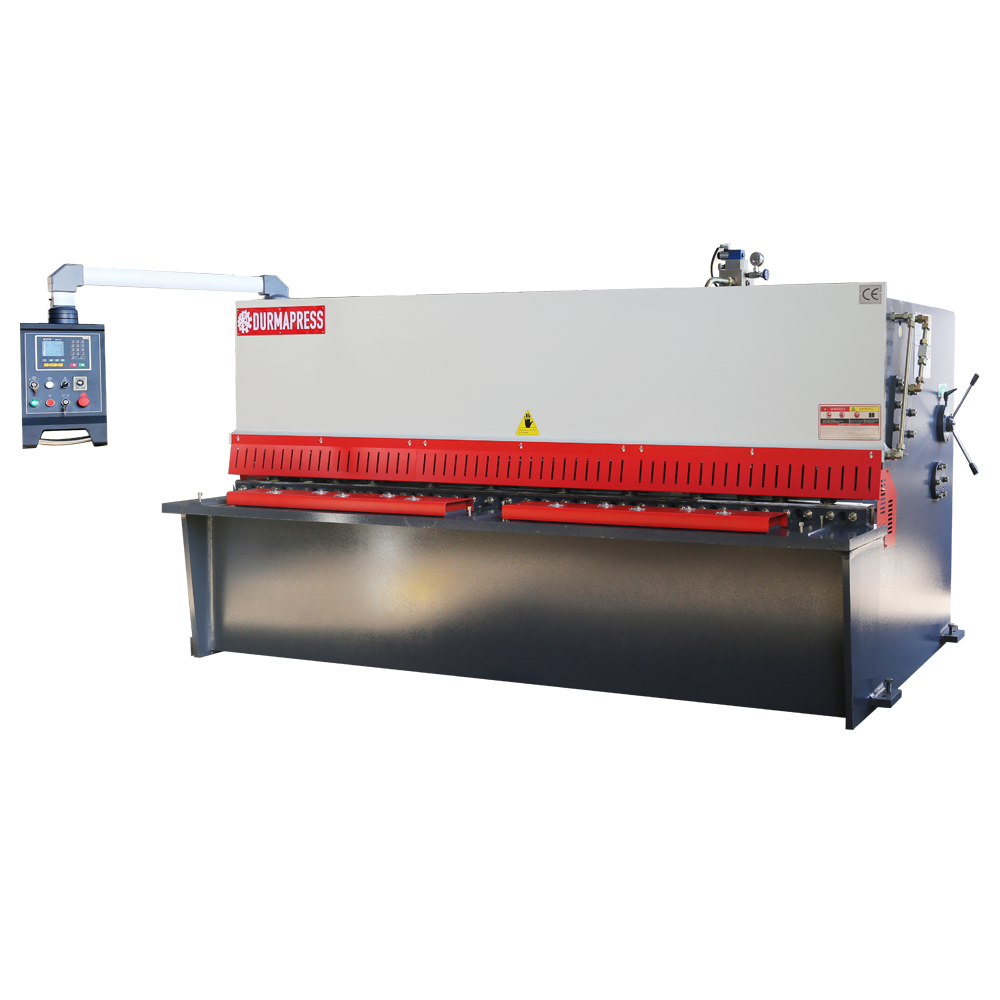

QC12K Series Swing Beam Shearing Machine

◆ The frame adopts an integral welded structure and is tempered by the fireplace;

◆ Hydraulic drive, nitrogen cylinder return stroke;

◆ The blade gap adjustment is indicated by a sign, which is convenient and quick to adjust;

◆ Equipped with light alignment device, and can steplessly adjust the stroke of the upper tool post;

◆ Adopt fence type safety protection device;

◆ Digital display of backgauge size and cutting times.

QC11K Series Guillotine Shearing Machine

◆ The frame adopts an integral welded structure and is tempered by the fireplace;

◆ Hydraulic transmission, accumulator return;

◆ Adopting three-point supporting rolling guide to improve the cutting quality;

◆ Rectangular blade, all four cutting edges can be used, long service life;

◆ The adjustment of the cutting edge gap is indicated by a sign, which is convenient and quick to adjust;

◆ Equipped with light alignment device;

◆ The stroke of the upper tool post can be adjusted steplessly;

◆ Using fence type safety protection device;

◆ Digital display of back gauge size and cutting times;

◆ The cutting angle is adjustable.

QC12Y Series Hydraulic Swing Beam Shearing Machine

Thickness Thin plate with better cutting quality.

- Model: QC12Y Series

- Controller: E21s

- Capabilities: Max. Thickness 20mm

QC12K Series Hydraulic Swing Beam Shearing Machine

Thin Thickness Plate for CNC Controller

- Model: QC12K Series

- Controller: E200P , DAC310S

- Capabilities: Max. Thickness 20mm

QC11Y Series Hydraulic Guillotine Shearing Machine

Adjustable Cutting Angle for thicker plate

- Model: QC11Y Series

- Controller: E21S

- Capabilities: Max. Thickness 40mm

QC11K Series Hydraulic Heavy Duty Guillotine Shearing Machine

6 Meters Heavy Duty CNC Shearing Quality

- Model: QC11K Series

- Controller: E200P , DAC360S

- Capabilities: Max. Thickness 40mm

Shearing Machine Video

DURMAPRESS®Different Series Mild Steel Shearing Machines with CNC Controller Working Video Testing Before Delivery, Welcome Contact Us!

Upgrade Solutions

If you need to purchase separate accessories or services to renovate the Shearing Machines, you can learn more through the link below.

Shearing Machine Controller

BackGauge Pneumatic Support

Material Feeder

Laser Protection System

Knowledge of Shearing Machine

What is Shearing Machine?

The Hydraulic Shearing Machine which used to cut various thickness metal sheet by moving upper blade and the fixed lower blade , uses a reasonable blade gap to break and cut the plates according to the required size .

Classification of Shearing Machines

- Accordning to Upper Blade Movement Mode :

Pendulum shearing machine and Guillotine shearing machine

2. According to the power principle:

Mechanical shearing machine and Hydraulic shearing machine

3. According to the operation mode:

NC Hydraulic Shearing Machine and CNC Shearing Machine.

Swing Beam Shearing Machine V.S Guillotine Shearing Machine

Shears are machine tools used for cutting down sheet metal. Swing beam shearing machine moves with the upper blade in a circular arc. While Guillotine shear the upper beam moves straight down.

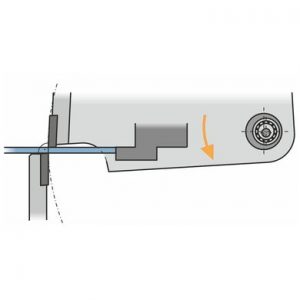

Swing Beam Type

Upper Blade Movement

Clean, right-angled cuts with almost no burr

Swing-type shearing machine usually adopts inclined blade shearing. It has been widely used because of its simple structure, low failure rate, high shearing efficiency and no distortion and warping after cutting. In the shearing process, as the tool rest does rotary movement, the angle and shearing gap of the swing-type shear will change.The machine is all steel welding structure. Hydraulic transmission, vibration to eliminate stress, and it has high strength and good rigidity. Hydraulic swing-type shearing machine do downward shearing movement and nitrogen cylinder return by using the main cylinder (fixed on the wall panel). So simplified the hydraulic system operates more stably. The upper tool rest of the swing-type shearing machine swings around a fixed axis in the shearing process. Through leverage, the fulcrum has little force, which can improve the life of shearing blade and machine. The whole machine is in compact structure, and can electrodelessly adjust the stroke of the upper tool rest, which greatly improves the working efficiency.

Function features:

In order to obtain high quality workpiece, shearing machine should be able to ensure the straightness and parallelism of the shear surface of the sheet after cutting, and minimize the plate distortion. The upper blade is fixed on the tool rest and the lower is fixed on the working table. Material supporting ball is set on the working table, so that the sheet material will not be scratched when sliding on it. The rear stopper is used for plate positioning, and the position is adjusted by the motor. The press cylinder is used to compress the sheet to prevent it from moving during shearing. The guardrail is a safety device to prevent accidents at work. The return usually depends on nitrogen, which is fast and has little impact.

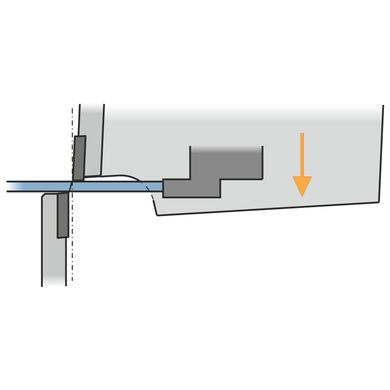

Guillotine Type

Upper Blade Movement

Suitable for cutting thin sheet material, up to thickness of 6 mm~40mm

Guillotine shearing machine uses frame structure with all steel welding.It has four angle, eight sides with a right-angle guide rail, high precision, good rigidity, and the use of hydraulic pre- tightening. The whole hydraulic system adopts two-way cartridge integrated valve,and can be configured with stroke digital display, photoelectric protection device and mobile table (convenient to change the mold). The gate-type shearing machine has a double function of both the upper slider and the lower hydraulic pad, the working pressure stroke can be adjusted in the specified range according to the process requirements, it is easy to operate with the centralized control button.

Function features:

- Use the whole welding frame structure and vibration aging treatment. The machine has good rigidity, high precision and good precision retention.

- Use three-point supporting axle rolling guide rail. The upper tool rest roll gaplessly in the rolling guide rail. Rotating the hand wheel can adjust the service life of the blade.

- The movable blade support and four-eged long blade are provided for easy adjustment of blade gap uniformity, improve shear quality and prolong blade service life.

- Use tandem cylinder synchronization system. The machine is forced uniformly. By adjusting the flow of tandem cylinder,it is very convenient to adjust the shear angle, which can meet the needs of different shear plate thickness.

- Use motorized rear stopper device and electronic counter.It is convenient to adjust the position of rear stopper.

How to use the Shearing Machine ?

1. Start the shearing machine for several cycles of idling, to ensure that under normal conditions, try to cut sheets of different thicknesses, from thin to thick. Make sure the user is familiar with shearing machine performance.

2. Different blade gaps must be adjusted for different plate thicknesses during trial shearing. If the corresponding blade clearance is not adjusted, the blade durability will be affected.

3. Turn on the switch of the pressure gauge during the shearing process, observe the pressure value of the oil circuit, and the pressure should be less than 20MPa when cutting a 12mm plate. This remote pressure regulating valve No.9, the pressure is set at 20-22MPa when it leaves the factory, the user must abide by this regulation, and must not increase the pressure for shearing the surface of the material beyond the specified, causing damage to the machine.

4. The sound is balanced during operation. If the shearing machine is noisy, it should be stopped for inspection.

5. When the shearing machine is operating, the temperature of the fuel tank should be raised to less than 60 degrees, and when it exceeds, it will be shut down and rested.

Tips When Working the Shearing Machine ?

1. The shearing machine must be managed by a special person.

2. A shearing machine is not allowed to cut two materials of different specifications at the same time. When two people cooperate to cut materials, they must be commanded by one person to strengthen the connection, and the movements of their hands and feet are consistent.

3. Before starting the machine, carefully check whether the rotating parts of the machine tool, safety devices, lubrication systems, upper and lower knives, etc. are normal.

4. After the machine is started, idle for a few cycles first, and then start the operation after ensuring that there is no abnormality.

5. Sundries and tools are not allowed to be stacked on the machine table, so as to keep the machine tool and the site clean at all times.

6. After driving for work, it is not allowed to use the car in order to save trouble. You should lift your foot from the pedal every time you step on the pedal once, and you need to open the empty car for inspection. It is strictly forbidden to start suddenly.

7. If the machine is found to be running abnormally during use, immediately cut off the power supply and stop for inspection.

8. All parts of the machine tool should be kept lubricated frequently. The operator should add lubricating oil once in each shift, and the rolling bearing parts should be filled with lubricating oil once every six months.

9. After the work is completed, cut off the power supply and lock the power box.

Write us today

Write us today and our experts are ready to help. You can contact us by the contact form below or write us email or make a phone call!