Processo de corte principal e tecnologia de corte chave da máquina de corte a laser

Main process types of laser cutting machine

1、Vaporization cutting

Vaporization is a non-metal cutting process that keeps the laser beam in one place until the working material is heated and evaporated. It also uses inert gas injection. However, the main goal is to remove the evaporated particles rather than prevent oxidation. During the laser vaporization cutting process, the surface temperature of the material rises to the boiling point very quickly, which can avoid melting caused by heat conduction. Therefore, part of the material vaporizes into steam and disappears, and part of the material is blown away from the bottom of the slit as ejecta by the auxiliary gas flow. In this case, very high laser power is required. To prevent the material vapor from condensing on the slit wall, the thickness of the material must not exceed the diameter of the laser beam. Therefore, this processing is only suitable for applications where the removal of molten material must be avoided. This type of processing is only used in a small area of use for iron-based alloys. It cannot be used for materials such as wood and some ceramics, that is, materials that are not in a molten state and therefore less likely to allow the material vapor to recondense. In addition, these materials usually have to achieve thicker cuts. In laser vaporization cutting, the optimal beam focus depends on the material thickness and the beam quality. The laser power and the heat of vaporization have only a certain influence on the optimal focus position. For a certain sheet thickness, the maximum cutting speed is inversely proportional to the vaporization temperature of the material. The required laser power density is greater than 108W/cm2 and depends on the material, the cutting depth, and the beam focus position. Assuming sufficient laser power, the maximum cutting speed is limited by the gas jet speed for a certain sheet thickness. Laser vaporization can be used for low-melting-point metals such as tin or lead. However, these metals are more suitable for traditional processing technologies. Laser vaporization can also cut non-metallic materials (paper, fabric, wood, plastic, rubber, etc.). It is used for non-industrial design and manufacturing work, such as art, furniture design, etc.

2、 Melting cutting

In laser melting cutting, the workpiece is partially melted and the molten material is ejected with the help of an air flow. Because the transfer of material only occurs in its liquid state, the process is called laser melting cutting. The laser beam is combined with a high-purity inert cutting gas to force the molten material to leave the slit, while the gas itself does not participate in the cutting. Laser melting cutting can achieve higher cutting speeds than gasification cutting. The energy required for gasification is usually higher than the energy required to melt the material. In laser melting cutting, the laser beam is only partially absorbed. The maximum cutting speed increases with increasing laser power and decreases almost inversely with increasing plate thickness and increasing material melting temperature. When the laser power is constant, the limiting factors are the gas pressure at the slit and the thermal conductivity of the material. Laser melting cutting can obtain oxidation-free cuts for iron and titanium. The laser power density that produces melting but not gasification is between 104W/cm2 and 105W/cm2 for steel. The metal materials cut are aluminum, copper, steel, nickel, titanium, etc. It is usually used for large-volume and low-precision production.

3、 Oxidation melting cutting

Melting cutting generally uses inert gas. If oxygen or other active gases are used instead, the material is ignited under the irradiation of the laser beam, and a violent chemical reaction occurs with oxygen to generate another heat source, which further heats the material. This is called oxidation melting cutting. Due to this effect, for structural steel of the same thickness, the cutting rate obtained by this method is higher than that of melting cutting. On the other hand, this method may have a worse cut quality than melting cutting. It will generate a wider kerf, obvious roughness, increased heat-affected zone, and worse edge quality. Laser flame cutting is not good for processing precision models and sharp corners (there is a risk of burning the sharp corners). Pulsed mode lasers can be used to limit the heat effect, and the power of the laser determines the cutting speed. When the laser power is constant, the limiting factor is the supply of oxygen and the thermal conductivity of the material. It can cut thick materials (steel, stainless steel, and aluminum), manufacture metal blanks (blank shapes for further processing), and manufacture heavy machinery.

4、Controlled fracture cutting

For brittle materials that are easily damaged by heat, high-speed and controllable cutting is performed by laser beam heating, which is called controlled fracture cutting. The main content of this cutting process is: that the laser beam heats a small area of brittle material, causing a large thermal gradient and severe mechanical deformation in the area, resulting in cracks in the material. As long as the heating gradient is balanced, the laser beam can guide the cracks to form in any desired direction. High-hardness materials (alumina ceramics, glass, silicon carbide, etc.) can be used to cut gems (zirconia, ruby, etc.).

Mechanism analysis of the main process types of laser cutting machines

1、Mechanism analysis of vaporization cutting

Both metal materials and non-metallic materials have a fixed boiling point, such as the boiling point of iron is 2966 degrees Celsius. When the external temperature reaches the boiling point of these materials, the material will begin to vaporize and form steam. The mechanism of laser vaporization cutting is to use a high-energy laser beam as a heat source to make the mechanical material reach the boiling point and vaporize in an instant. Due to the high temperature, high-speed steam will be generated in a short time, leaving a neat cut on the material. Laser vaporization cutting requires the laser to have a large power, so this cutting method is usually used to cut thin metal sheets with a small thickness, or some non-metallic materials with a low boiling point, such as wood, plastic, etc.

2、Analysis of the mechanism of melting cutting

Laser melting cutting also first uses the instantaneous high temperature of the laser to melt the material. Unlike vaporization cutting, after the material is melted, a non-oxidizing gas needs to be blown to the laser irradiation point with a nozzle coaxial with the beam. Relying on the strong pressure of the nozzle, the melted material does not need to completely vaporize the mechanical equipment. Therefore, the required processing capacity is relatively small, usually only 10%-15% of vaporization cutting. Commonly used non-oxidizing gases are helium and argon. The main materials for melting cutting are active technical materials, such as aluminum, steel, titanium alloy, etc.

3、Analysis of the mechanism of oxidation melting cutting

In terms of effect, laser oxidation melting cutting is similar to oxyacetylene cutting. Both use preheating heat sources and use active gases such as oxygen and hydrogen as cutting gases, while the preheating heat source of laser oxidation melting cutting is laser. The difference between laser oxidation melting cutting and the above two cutting methods is that it directly uses active gases to cut metal materials: the ejected gas can produce a large amount of oxidation heat on the one hand. On the other hand, the high-speed gas can also blow out the molten metal and oxide to form an incision. Since the active gas releases a lot of heat in the oxidation reaction, it plays a role in melting metal materials to a certain extent, so the energy consumed by cutting is relatively low.

Key cutting technology of laser cutting machine

1、 Focus position control technology

2、Cutting and perforating technology

Any thermal cutting technology, except for a few cases where it can start from the edge of the plate, generally requires a small hole to be punched in the plate. Earlier, on laser stamping composite machines, a punch was used to punch a hole first, and then a laser was used to start cutting from the small hole. Cutting and perforating technology: Any thermal cutting technology, except for a few cases where it can start from the edge of the plate, generally requires a small hole to be punched in the plate. Earlier, on laser stamping composite machines, a punch was used to punch a hole first, and then a laser was used to start cutting from the small hole. For laser cutting machines without stamping devices, there are two basic perforating methods: (1) blasting perforation: (Blast Drilling), after continuous laser irradiation, a pit is formed in the center of the material, and then the oxygen flow coaxial with the laser beam quickly removes the molten material to form a hole. Generally, the size of the hole is related to the thickness of the plate. The average diameter of the blasting hole is half of the plate thickness. Therefore, the blasting hole diameter of thicker plates is larger and not round. It is not suitable for parts with higher requirements (such as oil sieve pipes) and can only be used for waste materials. In addition, since the oxygen pressure used for perforation is the same as that for cutting, the spatter is larger. (2) Pulse perforation: Drilling) uses a high peak power pulsed laser to melt or vaporize a small amount of material. Air or nitrogen is often used as an auxiliary gas to reduce the expansion of the hole due to exothermic oxidation. The gas pressure is lower than the oxygen pressure during cutting. Each pulse laser only produces a small particle jet, which gradually penetrates deeper, so it takes a few seconds to perforate thick plates. Once the perforation is completed, the auxiliary gas is immediately replaced with oxygen for cutting. In this way, the perforation diameter is smaller and the perforation quality is better than that of blasting perforation. The laser used for this purpose should not only have a higher output power; more importantly, the time and space characteristics of the beam, so the general cross-flow CO2 laser cannot meet the requirements of laser cutting.

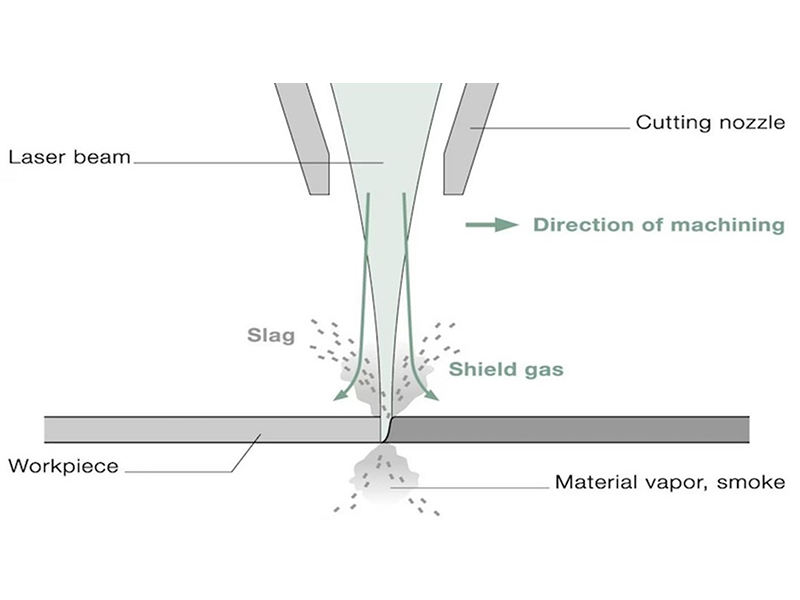

3、Nozzle design and airflow control technology

Nozzle design and airflow control technology: Laser cutting steel When cutting steel, oxygen and a focused laser beam are shot through the nozzle to the material being cut, thus forming a gas flow beam. The basic requirements for the gas flow are that the gas flow entering the incision should be large and the speed should be high, so that sufficient oxidation can fully cause the incision material to react exothermically; at the same time, there should be enough momentum to eject the molten material. Therefore, in addition to the quality of the beam and its control, which directly affect the cutting quality, the design of the nozzle and the control of the gas flow (such as the nozzle pressure, the position of the workpiece in the gas flow, etc.) are also very important factors. The nozzle used for laser cutting adopts a simple structure, that is, a conical hole with a small round hole at the end, which is usually designed by experimental and error methods. Since the nozzle is generally made of copper, it is small in size and is a vulnerable part that needs to be replaced frequently, so fluid mechanics calculations and analysis are not performed. When cutting steel, oxygen and a focused laser beam are shot through the nozzle to the material being cut, thus forming a gas flow beam. The basic requirements for the gas flow are that the gas flow entering the incision should be large and the speed should be high, so that sufficient oxidation can fully cause the incision material to react exothermically; at the same time, there should be enough momentum to eject the molten material.

Competitive advantages of using laser cutting machines

1、Good cutting quality

It is suitable for cutting precision accessories and fine cutting of various craft words and paintings. It has the characteristics of high precision and high accuracy. The laser beam can accurately control the cutting position and shape, making the cutting process very precise. Therefore, in the field of manufacturing, especially in the field that requires high-precision parts, the versatility of laser cutting machines has been greatly improved.

2、 High cutting efficiency

Laser cutting machines have high-speed cutting capabilities. The high energy density generated by the laser beam makes the cutting speed very fast, which greatly improves production efficiency. Compared with traditional mechanical cutting tools, laser cutting machines can complete cutting tasks faster.

3、Low cost and more affordable

Laser cutting has economic advantages over other CNC machine tools of the same caliber, which is one of the advantages of laser technology. Thanks to laser cutting technology, custom tools are no longer required. You also don't need to modify the equipment for any project because no additional cutting tools are required. In addition, there is no physical contact, so there is no wear on the surface. Since laser cutting machines have few mechanical parts, their maintenance costs are lower than other processing technologies. The operating costs of the machine will also be lower than those of traditional manufacturing tools.

Sobre nós

A Durmapress é especializada na conceção, fabrico e venda de vários equipamentos de processamento de metal, incluindo máquinas de dobragem, tesouras, punções, máquinas de corte a laser, etc. A empresa foi fundada em 2000. Com anos de experiência e acumulação de tecnologia. DurmaPress tornou-se uma das marcas bem conhecidas na indústria de máquinas de processamento de metal da China.

Contactar-nos

Publicações recentes

Categorias

Siga-nos

Novo vídeo semanal

Contacte-nos para mais informações

Se tiver alguma informação sobre os nossos produtos, contacte-nos e responderemos no prazo de 24 horas.

-300x169.jpg)