Hydraulic Shearing Machine

General Features

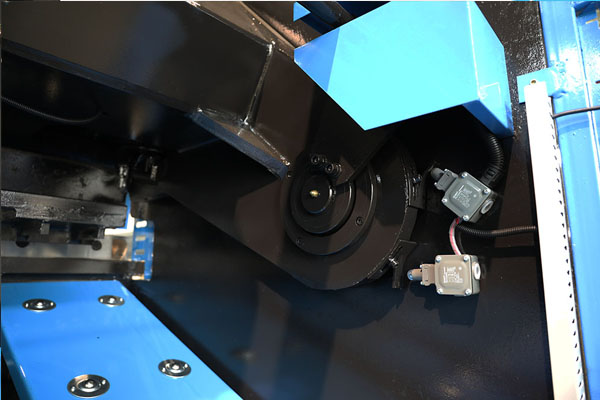

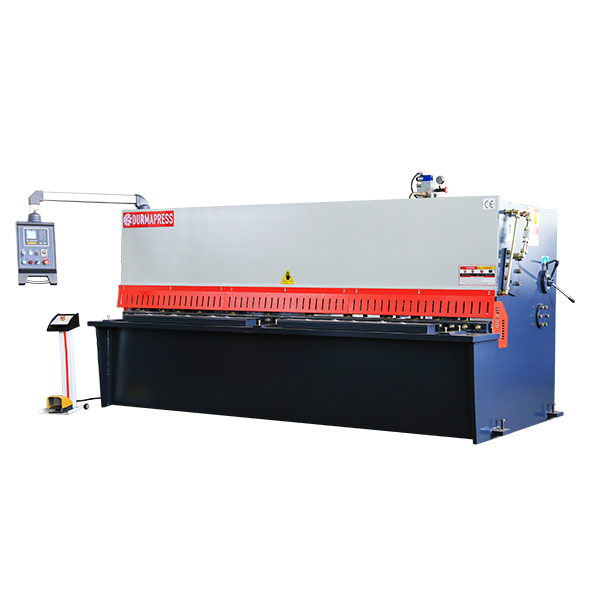

- Steel plate welded structure, hydraulic transmission, nitrogen cylinder return

- Easy operation, reliable performance, beautiful appearance

- The blade gap adjustment has a sign indication, the stepless adjustment is light and rapid

- It has a light alignment device and can adjust the stroke of the top blade holder steplessly.

- With hydraulic and electrical overload protection

- Rolling material support ball will reduce the scratch and frictions as well

- Adopt safety protection fence for the safety of workers

- Straightness: ±0.10mm for 3m plate cutting

- 50% faster than others (30 times/min for our 4x2500 shear while others is only 12 times/min)

- Blade material:6CrW2Si

- Heat treatment: 55°-60°HB

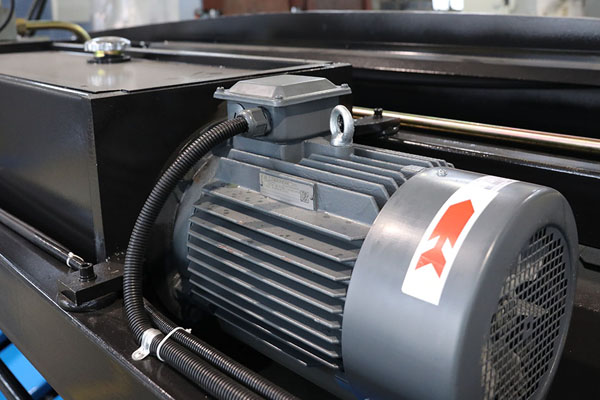

- Low noise (70bd), gear pump drive by hydraulic

- E21s, E200PS, DAC310S CNC system can be selected

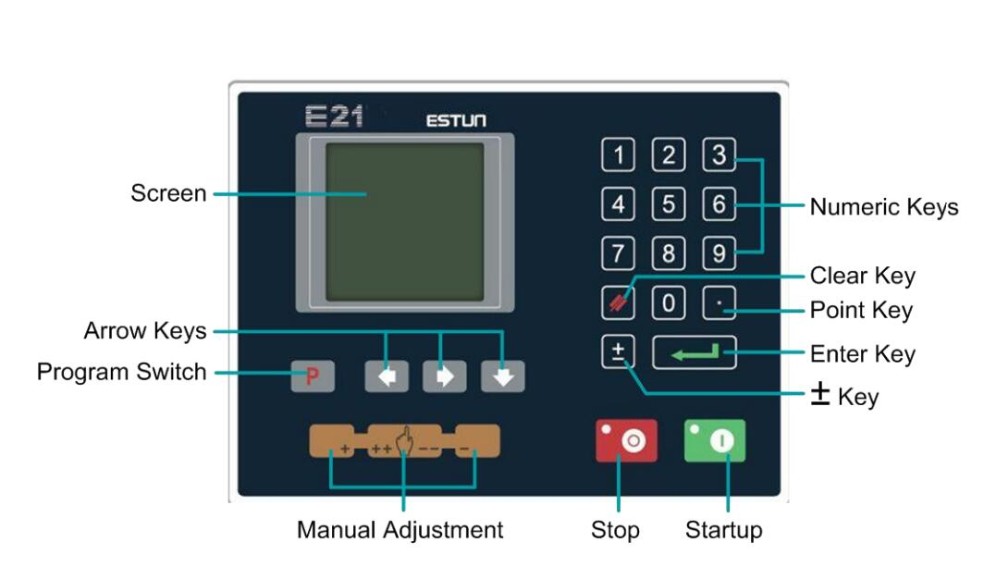

E21S NC Controller From ESTUN

Controller Data

- High-definition LCD display with Chinese and English language options. Programming parameters can be displayed on one page, making programming faster and more convenient.

- Backgauge: Intelligent positioning, manual adjustment can also be performed as needed, and mechanical manual positioning device is eliminated.

- Shearing stroke: Built-in shearing time relay, easy operation and cost saving.

- Cutting angle: built-in cutting angle adjustment function, eliminating the angle indicator and buttons.

- Knife edge clearance: encoder feedback, timely display of knife edge clearance, easy and convenient operation.

- With one-key parameter backup and recovery function, parameters can be restored at any time as needed, reducing maintenance costs.

- All keys on the panel are micro switches, which have passed strict tests such as EMC, high and low temperature, and vibration to ensure product stability and service life.

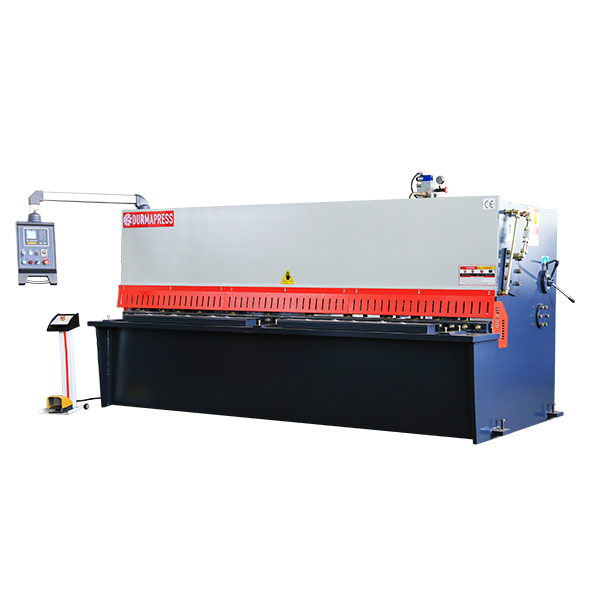

Hydraulic Shearing Machine

E21s NC Hydraulic Shearing Machine Working Video

◆ The host adopts the structure of QC12Y series hydraulic pendulum shears;

◆ The numerical control system selects the economical numerical control system dedicated to the shearing machine;

◆ The back gauge screw uses imported ball screw + linear guide.

Estrutura da máquina

Shearing machine is a kind of shear which is widely used in machining

Hydraulic pendulum shears

Hydraulic Swing Beam shears

Cutting equipment, which can cut steel plates of various thicknesses. Commonly used shears are divided into three types: flat shear, rolling shear and vibration shear. Flat shears are used in large quantities. Shears with a cutting thickness of less than 10mm are mostly mechanically driven, and those with a thickness greater than 10mm are hydraulically driven. Generally use pedal or button operation for single or continuous cutting of metal

Electrical Parts

The Shearing Machine Adopted French schneider electrics to ensure machine stability , High quality electric parts can perform well even the electricity is not stable and customs can easily get the replacement anywhere in the world

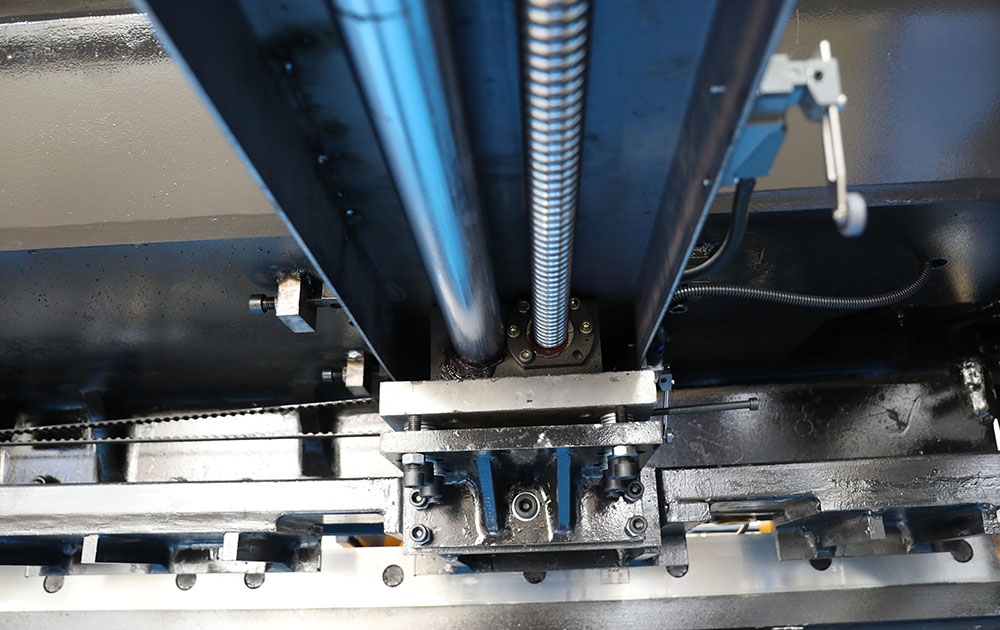

Ball Screw

High-Precision back guage device , fine ball screw and polished rod structure , high performance motor drive ,ensuring the positioning accuracy , unique timing transmission mechanism , reliable and stable

OTHER COMPONENTS

-

- Siemen Motor

-

- EMB Tube

-

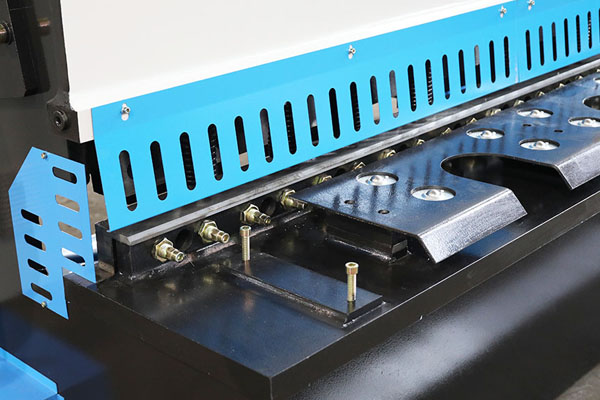

- Manual Knife Clearence

-

- Press Cylinder

-

- Shearing Blade

-

- Foot Pedal

-

- Rexroth Valve

-

- Working Table

-

- Knife adjust

TECHNICAL DATA

| Seri-al NO. | Nome | Numerical value | Unit | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4x1500 | 4x1600 | 4x2500 | 4x3200 | 4x4000 | 4x6000 | 6x2500 | 6x3200 | 6x4000 | 6x6000 | 8x2500 | 8x3200 | 8x4000 | 8x6000 | 10x2500 | 10x3200 | 10x4000 | 10x4000 | |||||||||||||||||||||||

| 1 | Max. Cutting Thickness | 4 | 4 | 4 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | mm | ||||||||||||||||||||

| 2 | Max.Cutting Length | 1500 | 1600 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 4000 | mm | ||||||||||||||||||||

| 3 | Strength of sheared plate | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | N/m㎡ | ||||||||||||||||||||

| 4 | Cutting Angle | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°30 | 1°40 | 1°40 | 1°40 | 1°40 | |||||||||||||||||||||

| 5 | Number of strokes | 44483 | 44483 | 8-14 | 8-14 | 8-14 | 8-14 | 8-14 | 8-12 | 10 | 14 | 14 | 14 | 14 | 10 | 14 | 14 | 14 | 14 | Hits/min | ||||||||||||||||||||

| 6 | Length of Cutter Blade(A) | 1600 | 1600 | 2600 | 3300 | 4100 | 6100 | 2600 | 3300 | 4010 | 6240 | 2600 | 3300 | 4100 | 6100 | 2600 | 3300 | 4100 | 4100 | mm | ||||||||||||||||||||

| 7 | Height of working table above the ground (C) | 800 | 800 | 800 | 800 | 800 | 800 | 10-700 | 10-700 | 10-700 | 10-700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 700 | mm | ||||||||||||||||||||

| 8 | Backgauge Range of X Axis | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | 550 | mm | ||||||||||||||||||||

| 9 | Main Motor | Type | Y132S-4/(B35) | Y132S-4/(B35) | Y132S-4/(B35) | Y132S-4/(B35) | Y132S-4/(B35) | Y132S-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | 132M-4/(B35) | 132M-4/(B35) | 132M-4/(B35) | 132M-4/(B35) | Y180M-4/(B35) | Y180M-4/(B35) | Y180M-4/(B35) | Y180M-4/(B35) | ||||||||||||||||||||

| Power | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 | 11 | KW | |||||||||||||||||||||

| Rotate Speed | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | R/MIN | |||||||||||||||||||||

| 10 | Gear Pump | Type | CP0-10-10R | CP0-10-10R | CP0-10-10R | CP0-10-10R | CP0-10-10R | CP0-10-10R | CP1-25-10R | CP1-25-10R | CP1-25-10R | CP1-25-10R | NBZ-G25F | NBZ-G25F | NBZ-G25F | NBZ-G25F | CP1-32-P-10R | CP1-32-P-10R | CP1-32-P-10R | CP1-32-P-10R | ||||||||||||||||||||

| Norminal Flow | 10 | 10 | 10 | 10 | 10 | 10 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 32 | 32 | 32 | 32 | Ml/r | |||||||||||||||||||||

| Norminal Pressure | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | Mpa | |||||||||||||||||||||

| 11 | Back-gauge motor | Type | YS7134 | YS7134 | YS7134 | YS7134 | YS7134 | YS7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | ||||||||||||||||||||

| Power | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | KW | |||||||||||||||||||||

| Rotate Speed | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | R/min | |||||||||||||||||||||

| 12 | External Dimensions | Comprimento | 2320 | 2320 | 2820 | 3580 | 4630 | 6630 | 3030 | 3730 | 4800 | 6430 | 3050 | 3730 | 4530 | 6630 | 2830 | 3830 | 4630 | 4630 | mm | |||||||||||||||||||

| Width | 1420 | 1420 | 1520 | 1620 | 1850 | 1850 | 1700 | 1700 | 1850 | 2150 | 1700 | 1700 | 1700 | 1850 | 1950 | 1950 | 1950 | 1950 | ||||||||||||||||||||||

| Height | 1500 | 1500 | 1850 | 1900 | 1700 | 1700 | 1620 | 1620 | 1700 | 2600 | 1620 | 1620 | 1620 | 1700 | 1850 | 1850 | 1850 | 1850 | ||||||||||||||||||||||

| 14 | Machine Weight | 2600 | 2600 | 3600 | 4800 | 6600 | 8400 | 4600 | 5600 | 7600 | 14300 | 5500 | 6300 | 8200 | 19000 | 7200 | 7800 | 9200 | 9200 | Kg | ||||||||||||||||||||

| 15 | Power requirement | 380V (-15%,+15%) 50Hz ,3PH | ||||||||||||||||||||||||||||||||||||||