HYDRAULIC Heavy Duty Guillotine Shears

General Features

- The entire EU streamlined design, heat treatment frame, high rigidity workbench, optional mechanical

- compensation device for precise bending.

- Hydraulic synchronization control and Estun NC programmable logic controller ensure precise repeatability

- and ease of use.

- The integrated hydraulic system (Bosch Rexroth, Germany) can quickly and automatically switch to a slow bend.

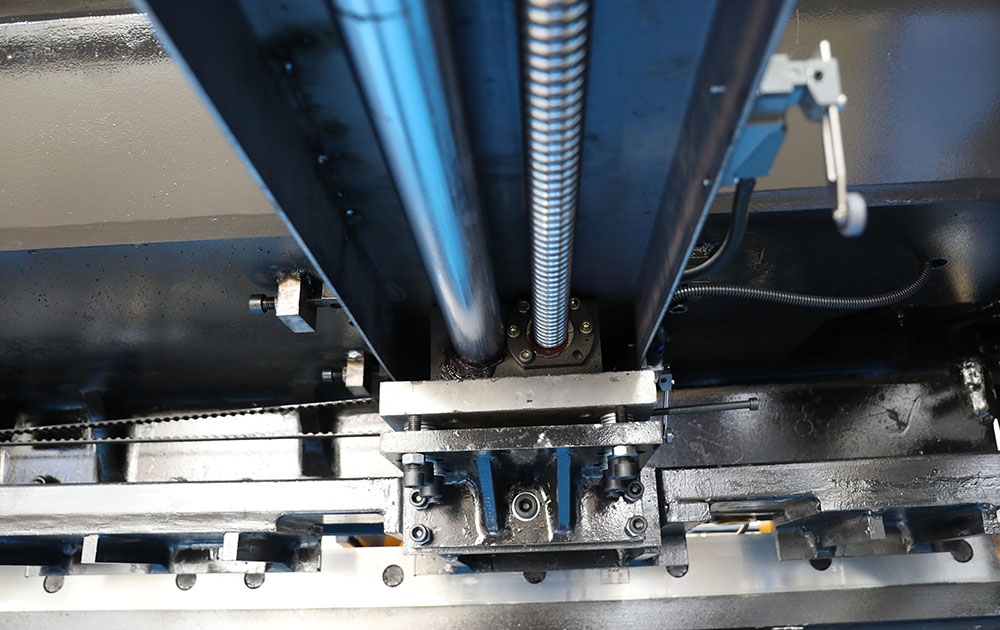

- The X-axis and Y-axis are programmed by the NC E21 system to achieve accurate positioning of the inverter.

- Advanced variable frequency hydraulic control technology, with more stable, and more reliable operation.

- The optimal parameter ratio and optimal core configuration ensure stable performance and convenient operation.

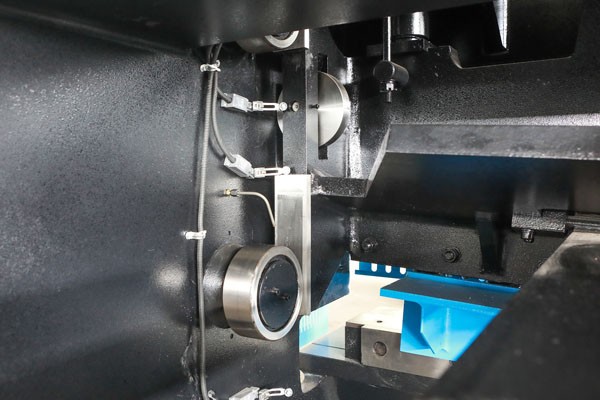

- WC67K series press brake equipped with standard single-axis backgauge system (X-axis) and single-axis bending

- angle system (Y-axis), you can choose to add V-axis compensation function, and select the appropriate mold to

- easily bend the workpiece with complex shapes.

E21 NC Controller From ESTUN

Controller Data

- ESTUN E21 is a simple NC control system designed to replace ESTUN E200 with lower price.

- ESTUN is jointed company by HOLLAND DELEM AND CHINA ESTUN

- ESTUN E21can control X axis working into position accurately

- ESTUN E21 will work better accompany with FREQUENCY

- FREQUENCY TRANSFORMER is not the standard components, optional.

- Can program the software for future usage and has memory

- Can set up different steps in one program

- Timer can control the bending time

- Control X/Y two axis

- The operation manual is available

- The install manual is available

Heavy Duty Shearing Machine Working Video

1. The machine adopts a split installation structure, which has sufficient strength and rigidity. The internal stress is eliminated through high-temperature annealing to ensure the overall accuracy of the machine.

2. Adopt German large floor boring and milling machine, and use one-time processing method for precision processing to ensure processing accuracy.

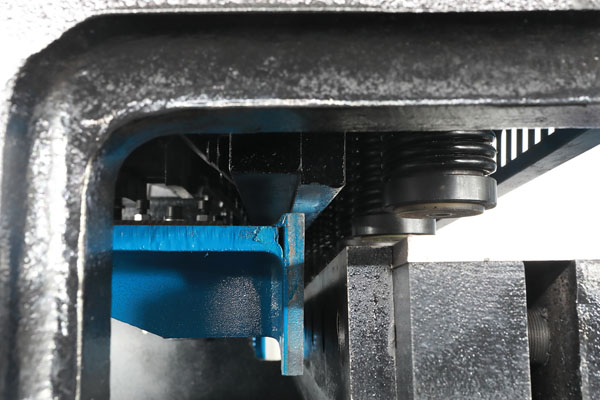

3. Hydraulic brake structure.

4. The hydraulic system adopts an integral logic circuit, controlled by a sequence valve, with smooth movement, low noise and simple maintenance.

5. Using domestic famous brand hydraulic valve to control the movement of the knife board and down.

6. The pressing device adopts an integrated circuit and independent parallel pressing cylinders, and the pressing device is equipped with rubber pads. When the sheet is not flat, it can be freely stretched and compressed on the sheet, and the pressing force can also be adjusted according to the material of the sheet. And the thickness can be adjusted automatically without damaging the board surface.

MAIN COMPONENTS

Estação de ângulo

Estação de tosquia

Estação de perfuração

OTHER COMPONENTS

Technical DATA

Seri-al NO. | Nome | Unidade | 6x3200 | 6x4000 | 8x2500 | 8x3200 | 8x4000 | 8x6000 | 12x2500 | 12x3200 | 12x4000 | 12x6000 | 16x2500 | 16x3200 | 16x4000 | 16x6000 | 20x3200 | 20x6000 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Seri-al NO. | Nome | Unidade | 6x3200 | 6x4000 | 8x2500 | 8x3200 | 8x4000 | 8x6000 | 12x2500 | 12x3200 | 12x4000 | 12x6000 | 16x2500 | 16x3200 | 16x4000 | 16x6000 | 20x3200 | 20x6000 | ||||||||||||||||||

| 1 | Max. Cutting Thickness | mm | 6 | 6 | 8 | 8 | 8 | 8 | 12 | 12 | 12 | 12 | 16 | 16 | 16 | 16 | 20 | 20 | ||||||||||||||||||

| 2 | Max.Cutting Length | mm | 3200 | 4000 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 | 2500 | 3200 | 4000 | 6000 | 3200 | 6000 | ||||||||||||||||||

| 3 | Strength of sheared plate | N/m㎡ | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | ||||||||||||||||||

| 4 | Cutting Angle | ° | 0.5-2.5 | 0.5-2.5 | 0.5-1.5 | 0.5-2.0 | 0.5-2.0 | 0.5-2.5 | 0.5-2.0 | 0.5-2.0 | 0.5-2.0 | 0.5-3.0 | 0.5-2.5 | 0.5-2.0 | 0.5-2.0 | 0.5-3.5 | 0.5-3.5 | 0.5-3.5 | ||||||||||||||||||

| 5 | Number of strokes | Hits/min | 6/12 | 6/12 | 6/12 | 6/12 | 6/12 | 5/8 | 6/10 | 6/10 | 6/10 | 6/10 | 8/12 | 6/10 | 8/12 | 4/8 | 5/8 | 5/8 | ||||||||||||||||||

| 6 | Length of Cutter Blade(A) | mm | 3300 | 4100 | 2600 | 3300 | 3300 | 6150 | 2600 | 3300 | 4100 | 6150 | 2600 | 3300 | 4500 | 6150 | 6150 | 6150 | ||||||||||||||||||

| 7 | Height of working table above the ground (C) | mm | 10-750 | 10-750 | 10-700 | 10-700 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | 10-750 | ||||||||||||||||||

| 8 | Backgauge Range of X Axis | mm | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-600 | 10-600 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | 10-800 | ||||||||||||||||||

| 9 | Main Motor | Type | Y132M-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | Y132M-4/(B35) | Y160M-4/(B35) | Y180M-4(B35) | Y180M-4/(B35) | Y180M-4/(B35) | Y180M-4/(B35) | Y180L-4/(B35) | Y180M-4/(B35) | Y200L-4/(B35) | Y180L-4/(B35) | Y180L-4/(B35) | Y180L-4/(B35) | Y225M-4/(B35) | ||||||||||||||||||

| Power | KW | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 18.5 | 18.5 | 18.5 | 18.5 | 22 | 22 | 30 | 22 | 22 | 30 | 45 | |||||||||||||||||||

| Rotate Speed | R/MIN | 1440 | 1440 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1440 | 1440 | 1440 | 1440 | |||||||||||||||||||

| 10 | Gear Pump | Type | NBZ3-G25F/CP1-25-P-10R | NBZ3-G25F/CP1-25-P-10R | NBZ3-G25F/CP1-25-P-10R | NBZ3-G25F/CP1-25-P-10R | NBZ3-G25F/CP1-25-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G63F/CP1-63-P-10R | NBZ4-G40F/CP1-40-P-10R | NBZ4-G50F/CP1-50-P-10R | NBZ4-G50F/CP1-50-P-10R | NBZ4-G50F/CP1-50-P-10R | NBZ4-G50F/CP1-50-P-10R | NBZ5-G80F/CP2-80-P-10R | ||||||||||||||||||

| Norminal Flow | Ml/r | 25 | 25 | 25 | 25 | 25 | 40 | 40 | 40 | 40 | 63 | 40 | 63 | 50 | 63 | 63 | 80 | |||||||||||||||||||

| Norminal Pressure | Mpa | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | 31.5 | |||||||||||||||||||

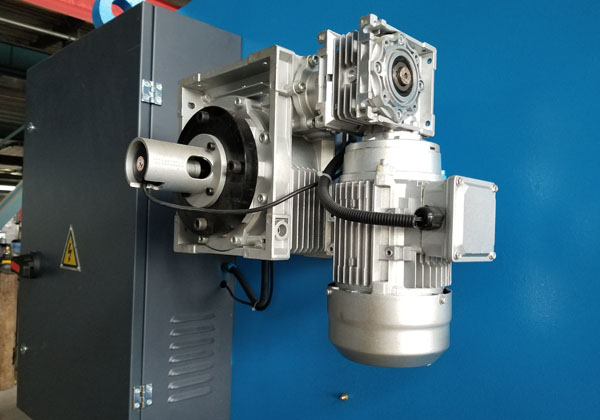

| 11 | Back-gauge motor | Type | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | YS-7134 | ||||||||||||||||||

| Power | KW | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.75 | |||||||||||||||||||

| Rotate Speed | R/min | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | |||||||||||||||||||

| 12 | External Dimensions | Comprimento | mm | 3700 | 4500 | 3000 | 3800 | 4500 | 6500 | 3100 | 3800 | 4500 | 6800 | 3100 | 3900 | 4600 | 6800 | 3900 | 6800 | |||||||||||||||||

| Width | 1800 | 1900 | 1800 | 1800 | 1800 | 2150 | 1900 | 1900 | 1900 | 2200 | 2000 | 2000 | 2000 | 2300 | 2000 | 2550 | ||||||||||||||||||||

| Height | 2000 | 2100 | 2100 | 2100 | 2100 | 2500 | 2300 | 2300 | 2300 | 2500 | 2400 | 2500 | 2400 | 2880 | 2500 | 2950 | ||||||||||||||||||||

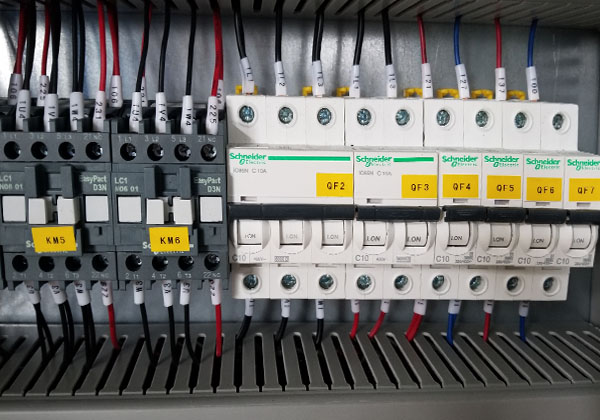

| 13 | Power requirement | 380V (-15%,+15%) 50Hz ,3PH | ||||||||||||||||||||||||||||||||||