HYDRAULIC NC Press Brake

General Features

- The entire EU streamlined design, heat treatment frame, high rigidity workbench, optional mechanical

- compensation device for precise bending.

- Hydraulic synchronization control and Estun NC programmable logic controller ensure precise repeatability

- and ease of use.

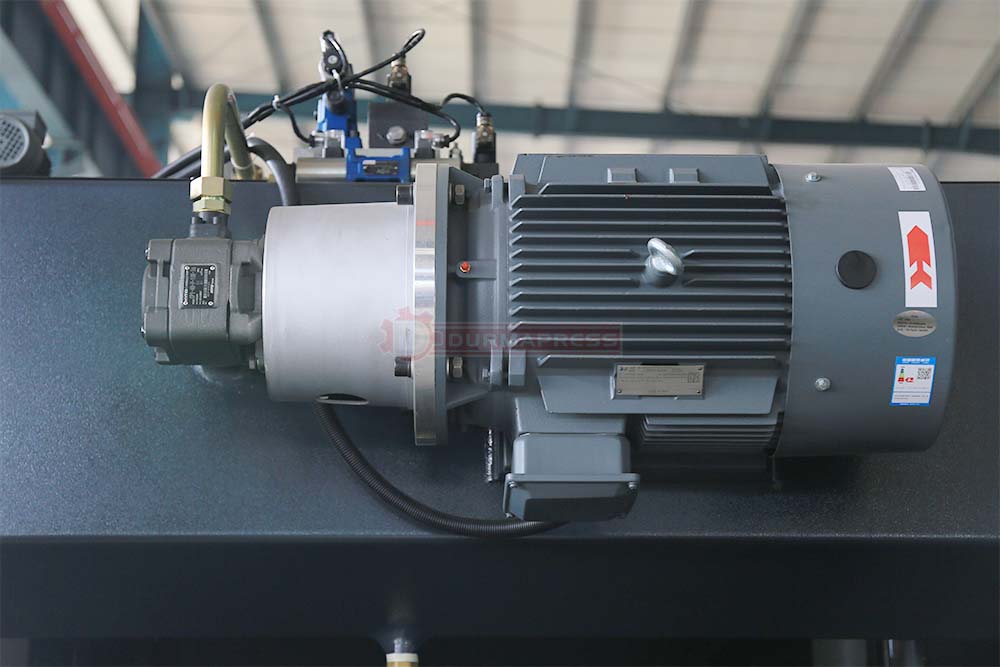

- The integrated hydraulic system (Bosch Rexroth, Germany) can quickly and automatically switch to a slow bend.

- The X-axis and Y-axis are programmed by the NC E21 system to achieve accurate positioning of the inverter.

- Advanced variable frequency hydraulic control technology, with more stable, and more reliable operation.

- The optimal parameter ratio and optimal core configuration ensure stable performance and convenient operation.

- WC67K series press brake equipped with standard single-axis backgauge system (X-axis) and single-axis bending

- angle system (Y-axis), you can choose to add V-axis compensation function, and select the appropriate mold to

- easily bend the workpiece with complex shapes.

E300P NC Controller From ESTUN

Controller Data

Control function, support X,Y,R axis servo axis control, C axis hydraulic/mechanical compensation two modes optional

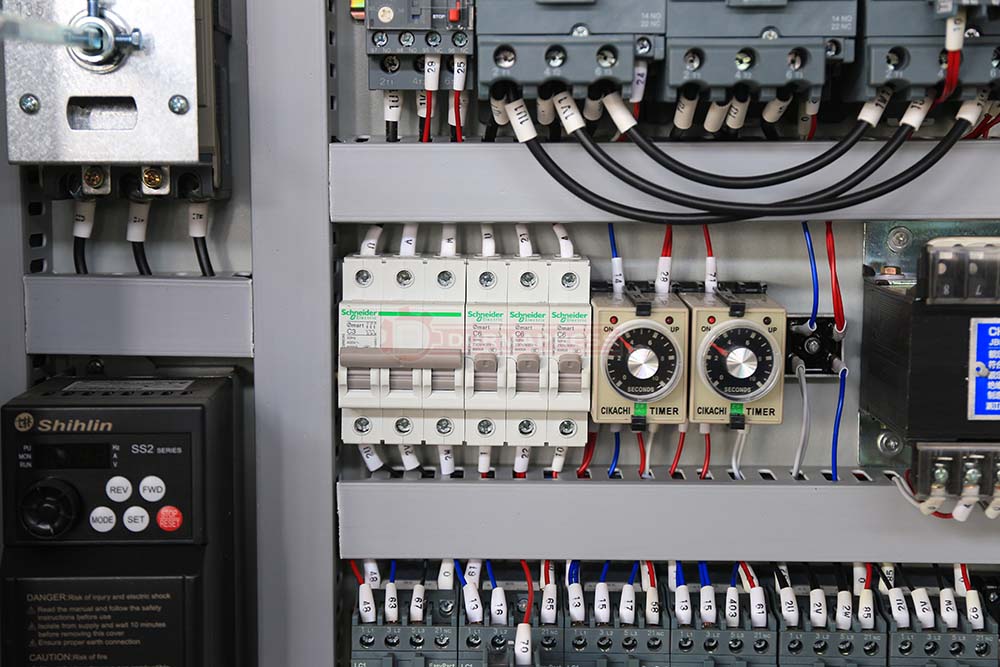

Built-in machine control logic, hydraulic valve group free logic configuration, I/O port free configuration function, simplifies the programming calculation of external line

Accurate Angle function, built-in mold base and material list, improved the calculating precision of

Standard USB interface, which can realize parameter program a key

Online backup and system software upgradeStandard EDS/ProNet servo series, superior performance, stable quality

Safety protection, collision detection and collision avoidance R axis positioning function

Built-in parameters a key to backup and restore function, reduce service costs

Micro switch according to the keypad, stable and reliable, long life

Componentes principais

- E300 CNC controller

- 2 axis control (Y、X )

- Grating ruler

- Germany ECKERLE oil pump

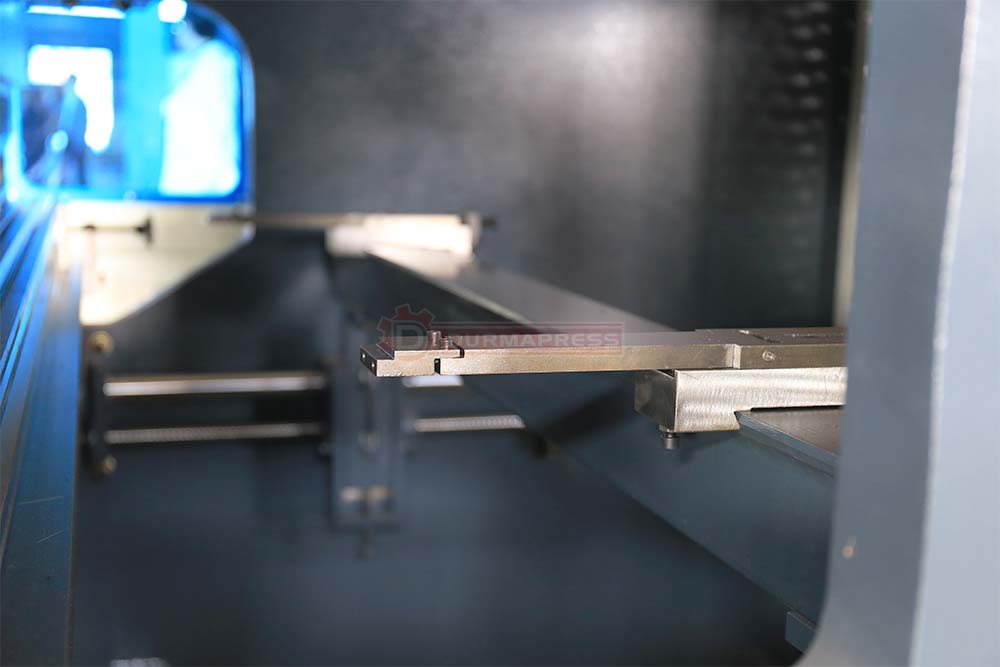

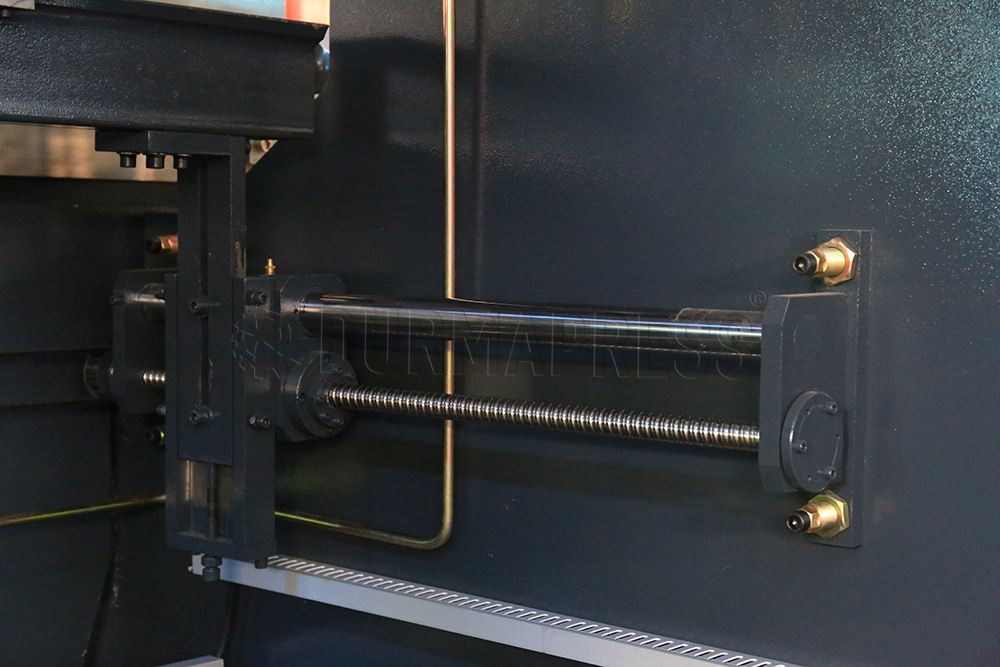

- Ball screw & linear guide -Taiwan PMI Backgauge positioning system

- Manual Movable front support arm X,Y axis

- NC control

- Fast Clamp

- Movable Support Arm with Linear Guide

- Standard type toolings and multi-V die

- Heyan Oil Cylinder (Shanghai)

- Servo Motor

Estrutura da máquina

The foundation of every Durmapress press brake is a solid, mono-block frame which made from high yield steel. Which means our press brakes will perform accurately and reliably year after year.

Every press brake frame is tempered.

We' re so confident in our frames so that we offer a 15-year warranty with our standard machines.

Back Gauge

We using the Taiwan PMI ball screw and linear guide to ensure the moving of X-axis with higher accuracy than using rod. And the backgauge adopt timing belt & wheel mechanism which controlled by servo motor instead of step motor. The height of the backgauge finger can be adjusted manually. Totally there're THREE pcs of backgauge fingers for positioning.

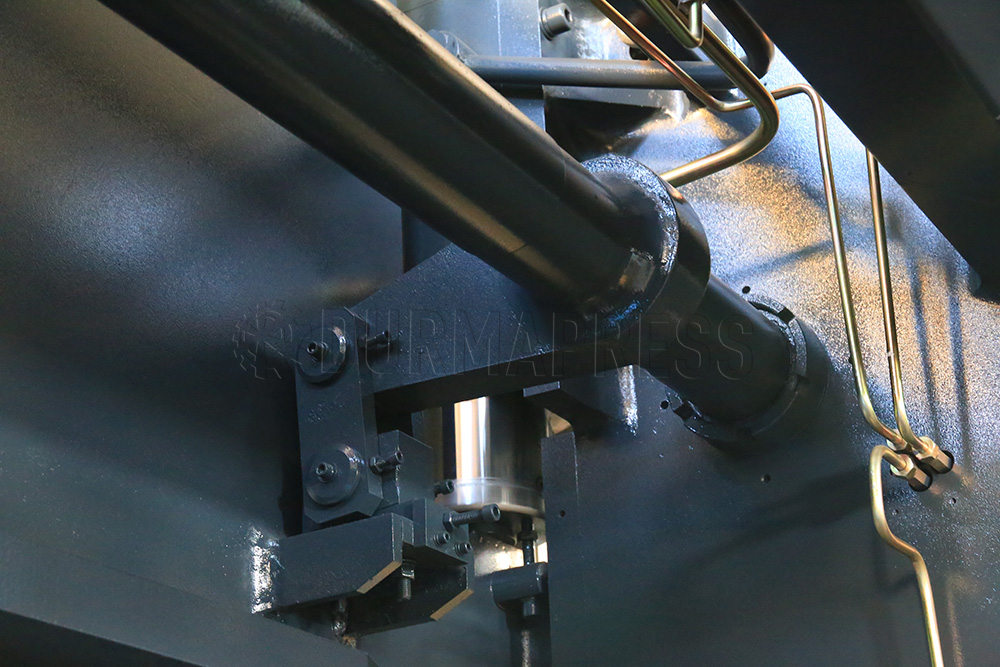

Toshion Bar

The torsion axis bending machine uses a torsion axis to link the left and right swing rods to form a torsion axis forcing a synchronous mechanism to move up and down the cylinders on both sides, so the torsion axis synchronous bending machine is a mechanical forced synchronization method, and the parallelism of the slider cannot be automatically checked Automatic mediation.

Working Video

CNC Hydraulic Press Brake Operations Video

Correct and safe operation of hydraulic bending machine

1. Strictly abide by the safety operation regulations of machine tool workers, and wear labor protection equipment as required.

2. Before using the equipment, check whether the fastening bolts, electric control box, and grounding device are in good condition. Before starting, check whether the motor, switch, circuit and grounding are normal and firm, and check that the control parts and buttons of the equipment are stuck in the correct position. .

3. When the equipment is used in winter when the temperature is lower than 0℃, it should be idle for a certain period of time to keep the oil temperature within the range of 15-60℃.

OTHER COMPONENTS

Dados técnicos

| Type | Nominal Force | Worktable Length | Poles Distance | Throat Depth | Stroke | Max Open Height | Power | Weight | Dimension |

|---|---|---|---|---|---|---|---|---|---|

| Unidade | (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | KGS | L*W*H(mm) |

| 30T/1600 | 300 | 1600 | 1280 | 200 | 80 | 285 | 3 | 1350 | 1600*1000*1600 |

| 35T/2000 | 350 | 2000 | 1480 | 200 | 80 | 285 | 4 | 1650 | 2000*1100*1800 |

| 40T/2200 | 400 | 2200 | 1850 | 230 | 100 | 320 | 5.5 | 2750 | 2200*1200*1910 |

| 40T/2500 | 400 | 2500 | 1850 | 230 | 100 | 320 | 5.5 | 3000 | 2500*1200*1910 |

| 50T/2500 | 500 | 2500 | 1850 | 230 | 100 | 320 | 5.5 | 3400 | 2500*1200*2000 |

| 63T/2500 | 630 | 2500 | 1900 | 250 | 120 | 320 | 5.5 | 4000 | 2500*1300*2210 |

| 63T/3200 | 630 | 3200 | 2500 | 250 | 120 | 320 | 5.5 | 4800 | 3200*1300*2210 |

| 80T/2500 | 800 | 2500 | 1900 | 300 | 120 | 320 | 7.5 | 5700 | 2500*1400*2300 |

| 80T/3200 | 800 | 3200 | 2500 | 320 | 120 | 350 | 7.5 | 6020 | 3200*1500*2300 |

| 80T/4000 | 800 | 4000 | 3000 | 320 | 120 | 350 | 7.5 | 7000 | 4000*1500*2400 |

| 100T/2500 | 1000 | 2500 | 1900 | 320 | 160 | 320 | 7.5 | 6000 | 2500*1600*2400 |

| 100T/3200 | 1000 | 3200 | 2500 | 320 | 160 | 370 | 7.5 | 6800 | 3200*1600*2600 |

| 100T/4000 | 1000 | 4000 | 3000 | 320 | 160 | 370 | 7.5 | 8400 | 4000*1600*2700 |

| 125T/3200 | 1250 | 3200 | 2500 | 320 | 160 | 370 | 7.5 | 7200 | 3200*1600*2600 |

| 125T/4000 | 1250 | 4000 | 3000 | 320 | 160 | 370 | 7.5 | 8800 | 4000*1600*2700 |

| 160T/3200 | 1600 | 3200 | 2500 | 320 | 200 | 460 | 11 | 10500 | 3200*1700*2700 |

| 160T/4000 | 1600 | 4000 | 3000 | 320 | 200 | 460 | 11 | 11500 | 4000*1700*2800 |

| 160T/5000 | 1600 | 5000 | 4000 | 320 | 200 | 460 | 11 | 14000 | 5000*1900*3100 |

| 160T/6000 | 1600 | 6000 | 4940 | 320 | 200 | 460 | 11 | 19500 | 6000*1900*3200 |

| 200T/3200 | 2000 | 3200 | 2500 | 320 | 200 | 460 | 11 | 10250 | 3200*1950*2800 |

| 200T/4000 | 2000 | 4000 | 3000 | 320 | 200 | 460 | 11 | 13600 | 4000*1950*2800 |

| 200T/5000 | 2000 | 5000 | 4000 | 320 | 200 | 460 | 11 | 14500 | 5000*1950*3000 |

| 200T/6000 | 2000 | 6000 | 5000 | 320 | 200 | 460 | 11 | 21000 | 6000*1950*3300 |

| 250T/3200 | 2500 | 3200 | 2500 | 400 | 250 | 590 | 18.5 | 19000 | 3200*2000*3200 |

| 250T/4000 | 2500 | 4000 | 3000 | 400 | 250 | 590 | 18.5 | 20200 | 4000*2000*3400 |

| 250T/5000 | 2500 | 5000 | 4000 | 400 | 250 | 590 | 18.5 | 23500 | 5000*2000*3400 |

| 250T/6000 | 2500 | 6000 | 5000 | 400 | 250 | 590 | 18.5 | 27500 | 6100*2200*3400 |

| 300T/3200 | 3000 | 3200 | 2600 | 400 | 250 | 590 | 22 | 20500 | 3200x2000x3450 |

| 300T/4000 | 3000 | 4000 | 3200 | 400 | 250 | 590 | 22 | 22500 | 4000x2000x3450 |

| 300T/5000 | 3000 | 5000 | 3800 | 400 | 250 | 590 | 22 | 25000 | 5000x2000x3450 |

| 300T/6000 | 3000 | 6000 | 4500 | 400 | 250 | 590 | 22 | 30000 | 6000x2000x3450 |

Write us today

Write us today and our experts are ready to help. You can contact us by the contact form below or write us email or make a phone call!